Historically, the evolution of protective head systems has been centered around lighter materials, enhanced protection against expanded and varied threats, improved coverage, fit and comfort, and scalability through shrouds, rail systems and add-on accessories. These critical advancements have led to significantly better protective helmet systems for those on the front lines.

Several years ago, the concept of “active” protection emerged, built on the idea that helmets needed to move from a purely protective productto a solution that increases survivability and lethality. These solutions integrate with modern equipment like hearing enhancement devices, night vision goggles, head-up displays, sensors, emitters, and computation. With the accelerated pace of innovation and the introduction of very new technologies like drones, robots, visual augmentation, advanced weapons platforms, and communicationsystems, etc., the future of head systems is capability-enhancement and integration focused.

Great product design is grounded in end-user feedback. The challenge, however, is that user feedback is inherently subjective, and often related to a ‘feeling’ rather than a quantifiable measure. With little detail beyond “that felt tight,” or “this was comfortable,” or “that felt a little unstable”, it can be difficult to translate subjective feedback into actionable product development decisions. Industry needs new tools in our collective toolbox in order to analyze the operational effectiveness of the warfighter as a system.

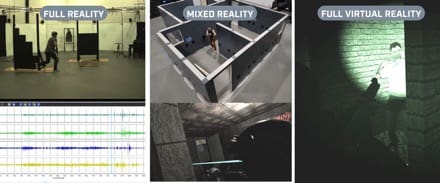

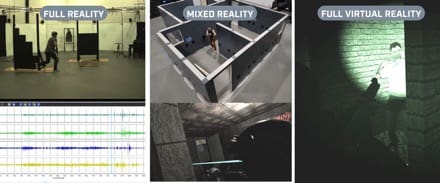

Galvion’s Warfighter Lab was purpose-built in our Portsmouth, New Hampshire headquarters, with state-of-the-art, custom-designed equipment, to measure and record performance under controlled andrepeatable conditions in an operationally immersive environment.Depending on the project, the questions posed, the type of end-user, the environmental conditions required, and the product or system being tested, the Warfighter Lab builds experiment protocols that include layers of simulation ranging from full reality to mixed reality to full virtual reality.

Dr. Martin Fultot, Manager of Galvion’s Warfighter Lab and an Experimental Psychologist explains, “We want to obtain behavioral responses and performance from the user that reliably reflect what would happen in the field. We do that by pushing the boundaries of immersion and suspension of disbelief; by blurring the lines between what is virtual and what is real. The simulated weapon you use is really in your hands, the wall you see is really there, etc. The level of immersion for our simulations is as advanced as we can get, given the current technology, allowing us to tap into deeply ingrained neuromuscular structures and processes to maximize the quality of the data and the validity of our conclusions.”

The Warfighter Lab allows our teams to move from ideation through iterations to implementation quickly and is at the center of new system developments, including Galvion’s Integrated Helmet System (IHS), a customized solution to meet the unique operational requirements of the U.S. Marine Corps (USMC). Galvion collaborated closely with Marines to incorporate real-time feedback, collected through multiple Limited User Evaluations (LUE) events, resulting in a purpose-built helmet system that provides an integrated head protection platform for the Marines.

One of the critical priorities discovered during feedback sessions was the need for superior stability. Marines voiced a willingness to trade comfort for stability and effectiveness, scoring NVG stability as essential. Galvion’s Engineering, Human Factors and Warfighter Labteams collaborated in an iterative development process to refineGalvion’s APEX™ suspension & retention system in order to ensure unmatched stability without compromising comfort. The results included a more robust fitband dial for easy adjustment even when wearing gloves, an improved harness camlock for quick adjustment, and a re-designed nape pad. The Warfighter Lab put the IHS helmet through stability testing under three conditions: helmet only, helmet with NVG, and helmet with NVG and counterbalance. Our internal design experiment demonstrated that overall performance with the helmet (shooting accuracy and speed) did not change, meaning the helmet can easily handle headborne accessories, validating overall stability of the helmet and APEX™ liner system design.

The ability to understand, measure and analyze exactly what new technology offers will be critical in assessing the tipping point between increased operational effectiveness and cognitive overload. How does each new technology impact overall warfighter survivability? Does it truly enhance performance or is it something that we, in theory, believe enhances performance? The Warfighter Lab is designed precisely to answer these new questions by collectingthe quantitative data needed to make product decisions in the era of the hyper-enabled warfighter.

Galvion will be exhibiting at Modern Day Marine Booth #943 (April 30-May 2nd, 2024) and at SOF Week Booth #948 (May 7-9th, 2024)

For more information related to Galvion’s IHS, please click here.