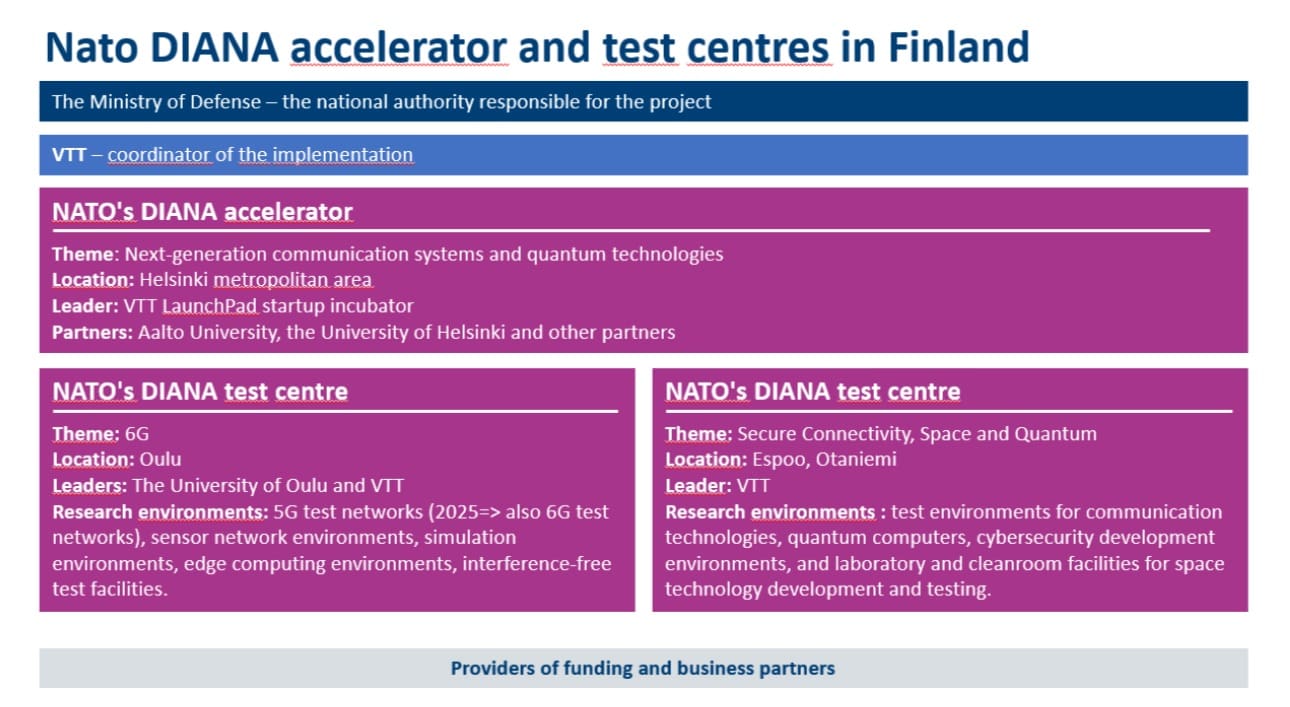

NATO’s DIANA (Defence Innovation Accelerator for the North Atlantic) programme is expanding its network with new sites. Finland is now part of the network since the Board of the DIANA initiative approved a proposal to establish an accelerator and two test centres in Finland. Their mission is to help companies develop technology, innovation and business for the civil and defence sectors.

The preparatory work, which started in spring 2023, was led by the Ministry of Defence and VTT Technical Research Centre of Finland and required input from several operators, has reached its desired conclusion. VTT is setting up a DIANA accelerator in Otaniemi, Espoo, in collaboration with Aalto University and the University of Helsinki. The test centres will be established at the University of Oulu and VTT’s Otaniemi site.

The operations to be established in Finland will build on decades of strong technological expertise and market success. The technology themes of the accelerator and test centres are related to next-generation communication systems, 6G technology, cybersecurity, quantum and space technologies.

“VTT is honoured to be part of the DIANA network and its accelerator and test centre activities. Finland’s world-class expertise helps pioneering companies to develop the deep technologies that will safeguard NATO and its billion inhabitants,” says Sauli Eloranta, Vice President, Defence at VTT.

DIANA accelerator to train companies to operate in the defence sector

VTT is setting up a DIANA accelerator in Otaniemi, Espoo, in collaboration with Aalto University and the University of Helsinki, which will focus on the communication systems and quantum technologies of the future. This will provide a special training programme that will help companies develop deep technologies and innovations for commercial and defence purposes. It will also provide companies with extensive and varied training on how to develop business opportunities in the defence sector.

The accelerator’s services will be specifically targeted at start-ups and SMEs with limited experience in the defence and security sector.

“The long-awaited decision is significant for Finland as it is the first time that Finnish operators will be able to harness their cutting-edge expertise for NATO’s DIANA innovation activities on such a large scale. Our country has a large number of technologically advanced and innovative start-ups and SMEs, which have found it difficult to invest in export in the defence sector. DIANA will support this activity free of charge by using the accelerators to train companies in NATO technical and procurement requirements and by developing company-specific business training programmes. Such a mechanism provides a high-speed lane for companies to enter a difficult but fastest growing industry internationally – I hope Finnish companies will participate as widely as possible,” says Eloranta.

DIANA selects companies for accelerators through its application process. This procedure is called the DIANA challenge programme. The first round of applications for the Finnish DIANA accelerator will be launched in 2024, and it will be open to start-ups developing dual-use solutions in NATO countries.

Test centres provide tools for further technological development

The technology test centres will be established at VTT’s Otaniemi site and the University of Oulu. VTT’s Otaniemi Test Centre will focus on secure connectivity, space and quantum technologies. The test centre at the University of Oulu will offer companies the opportunity to test 6G network technologies.

DIANA test centres are places where companies can strengthen their technological expertise and competitiveness. The research infrastructure and experts provided by the test centres will allow companies to evaluate their own concepts and technologies and get support to develop them. In practice, the test centres will consist of a comprehensive set of existing research facilities and equipment, as well as top-level expertise in the sector. The centres will also support the development of start-ups participating in the accelerator programme.

It will be possible for all companies in NATO countries to purchase the test centre services, regardless of whether or not they belong to a DIANA accelerator.

“Finland has a strong position as a developer of civilian communications systems, thanks to companies like Nokia. DIANA offers a fast track for many companies to enter the NATO defence market,” says Eloranta.

What is NATO’s DIANA initiative?

NATO’s DIANA initiative aims to identify future challenges in the defence and security sector and work with companies to find technological solutions.

“Part of DIANA’s strength is our unique transatlantic network of talent centres and innovation leaders working toward a common purpose. The breadth and diversity of partners in DIANA’s network will accelerate the development and deployment of ground-breaking solutions for defence, security and peace,” says Professor Deeph Chana, Managing Director of DIANA.

The initiative focuses on new technologies such as artificial intelligence, autonomy and quantum technologies, which are dual-use in nature, i.e. they can be commercially exploited in both the civil and defence sectors.

DIANA in brief

• NATO established DIANA to help develop dual-use technologies that meet security and defence challenges. DIANA supports companies working on solutions in key sectors identified by NATO member states.

• To meet the needs of a changing world, NATO is identifying, developing and deploying emerging and disruptive dual-use technologies.

• DIANA is NATO’s innovation accelerator, bringing together innovators from member states to support NATO’s technological leadership, defend its one billion citizens and maintain peace and security.

• DIANA provides companies with training, funding, commercial advice and access to defence expertise and investors. Participating companies are developing dual-use technologies to address major defence and resilience challenges.