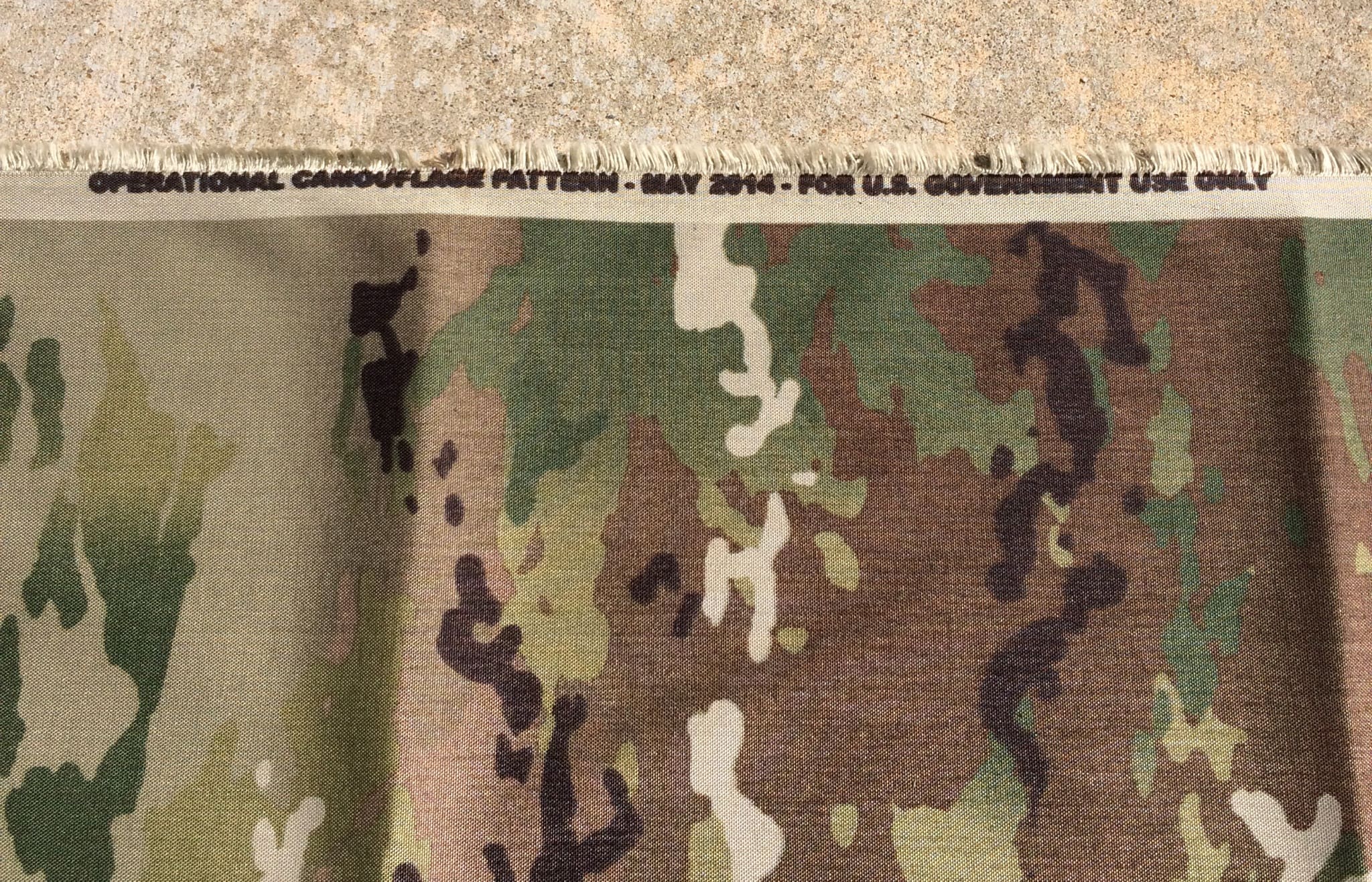

From the outset, I have to say that technically, the Army is just looking for a new fabric, as there has been no talk (at least publicly) about developing a specialized uniform layout for tropical environments. However, in addition to a new jungle boot that we talked about last week, Natick has released a Sources Sought Notice entitled, “Light Weight Tropical Uniform“. This is excellent news.

To read the meat and potatoes of what the Army is looking for, see it here at RFITropWeight.

This is an interesting move as it is an admission that the current fabric used in the ACU, a 50/50 NYCO or nylon/cotton blend adopted for the Enhanced Hot Weather Battle Dress Uniform in the early 90s isn’t really much of a tropical weight fabric. Prior to this, Hot Weather BDUs were made from a 100% ripstop cotton fabric. This came about as the Army “rediscovered” the need for a tropical weight version of the BDU during the invasion of Grenada in 1983. The Army had begun fielding the Woodland camouflaged BDU, made from a heavy, 50/50 nylon/cotton twill in 1981. Designed for use in central Europe, they were too hot for hot weather use. However, the comfortable, quick drying, 50/50 NYCO poplin fabric of the HWBDU was to be replaced within a decade.

By the early 90s, a serious garrison mentality had taken hold in the US Army. Soldier were starching their HWBDUs and the process was wearing them out rather quickly, with fraying at the cuffs and collars in as little as six months. Instead of telling Soldiers to stop starching a uniform fabric optimized for tropical environments, the Army introduced a new fabric that would be more durable when starched and pressed under high heat. Unfortunately, this 50/50 NYCO fabric compromise fabric isn’t so great in the hot weather environments the uniform was intended for. The nylon content lowers breathability, making the fabric feel warmer. Operational capability was abandoned in favor of looking good in garrison. When the ACU came along, the Army incorporated that same 50/50 NYCO poplin fabric. Now that the Pacific Pivot is in, and the Army is scrambling to recreate capabilities like the jungle boot that it had abandoned years ago, it has dawned on somebody that they can find a better fabric solution and I am glad.

Granted, the Universal Camouflage Pattern is an issue in the jungle and Woodland EHWBDUs are will in use by some Army SOF and students at the new US Army Jungle School in Hawaii. Hopefully, the Army will work out a solution for this dilemma. But, we can always look back to a simple solution fielded during the Viet Nam War.

I’ve called it “The Greatest Uniform Ever Fielded By The US Army” and in my opinion, the OG-107 Jungle Fatigue in 100% ripstop cotton remains just that.

In fact, this uniform, as well as the ERDL camouflaged variant, continued to be worn well into the late 80s by Special operations Forces.

Rightfully so, the Army is looking, at a minimum (threshold), for a no-drip, no-melt solution fabric story. Naturally, if the star’s aligned (object) they’d like a full FR solution, although this is probably overkill considering the operational environment.

If you’ve got something that you think will work, the Army needs to hear from you by 1200EST on 08 May 2014. They’ll also need 5 yards of fabric (any color) and a the usual slew of technical data. Make sure you read the details in the amendments. The Army is going to use this data to help scope an actual requirement, making this is a very important part if the process.

With so much development in the textile industry over the past 10 years, here’s to hoping that the Army identifies a fabric optimized for use in hot-wet environments.