When I was an E4 and living in the barracks, at least one to two washing machines were always broken due to over use. If I had this opportunity to use 10-20 Services, I would have jumped at the chance. What we are offering the Soldier is a great value at the price.

– Arlyn Slade, Eastern Zone Manager, 10-20 Services

10-20 Services is a company that specializes in the cleaning, retrofit, and repair of technical, tactical, and first responder gear. The 10-20 in their name refers to User and Organization levels in military field manuals, representing their capability to clean and service the gear of both users and full organizations. Originally located exclusively in Lakewood, Washington, since last year they have operated a Fort Bragg support facility in nearby Fayetteville, North Carolina. Just yesterday they added a handy drop-off kiosk at the Ft Bragg mini mall next to clothing sales. It offers the chance to drop off your dirty and damaged field equipment for the same cleaning and repair services offered to USSOCOM’s SPEAR Program. This kiosk offers a 24-hour cycle from drop off to pick up. Pricing is based on a per item menu.

10-20 has been a subcontractor supporting the sustainment of Special Operations individual equipment for many years from their Washington location. Last year’s expansion to Ft Bragg introduced additional cleaning and repair capacity in the direct support of Army operations.

In addition to the kiosk, we had to opportunity to tour their Fayetteville repair and cleaning facility. The facility, an unassuming climate-controlled building located in downtown Fayetteville, houses a full complement of cleaning and repair equipment, much of which is proprietary to 10-20 systems. Their process for processing and treating gear and clothing is a multi-step process which ensures every item is treated appropriately.

First, arrived items are placed into triage and inventoried. Condition is gauged for each individual item, and items are selected for pre-treatment as necessary.

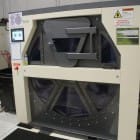

Afterwards, they clean the items using their Advanced Cleaning System. The Advanced Cleaning System consists of a specialized washing machine which utilizes a patented system of hydraulic pressure cleaning combined with a specific blend of environmentally-friendly detergents. Items remain stationary while in the system, allowing 10-20 Systems to wash items such as body armor, eye protection, boots, helmets, sleep systems, holsters, kneepads, and all manner of nylon gear, in addition to traditional garments such as uniforms and coveralls. The entire process is computer controlled, ensuring a consistent, effective cleaning process. Hard goods are disinfected to food grade standard, and the process is completely antimicrobial, removing 99.99% of bacteria, fungus, and viruses from the treated products.

Items are then racked and rolled into a specialized drying room. The room is set at a temperature of 106°F – 109°F and features a series of dehumidifiers which draw and suck moisture away from the gear as opposed of a traditional drying process. This method ensures fully dried gear which can be stored without fear of mildew or odors.

At this point, gear is then repaired in-house to mil-spec standards with Berry compliant materials. Items are then folded, packaged, coded, and labeled into the configuration outlined by the customer.

10-20 Services has contracts in place with SOCOM, US Army and US Marine Corps. Last year, they were also contracted to clean and service the US Army’s IOTV System.

Tags: 10-20 Services

Take that CIF!

Seriously. They ought to sell a shirt that says something like “CIF First-time GO”

Wow, I think this is great, I wish this had been around when CIF had CIF’d me some time in the past. I am sure many soldiers recall maintaining two sets of LBE/LCE, on for the field and one that belonged to the army. Funny story once I was issued all new gear for a short rotation of training, all new in plastic, I used my own LCE. When I turned the still sealed gear into CIF they would not take it. Said it was dusty, in the sealed, airtight plastic.

Final thought the army should provide this service for soldiers for free.

I had a similar experience clearing CIF with new in plastic gear once.

I’ve cleared Bragg twice. The first time it was obnoxious. Things were much more sane the second time. I heard IG did an investigation and caught them doing the sealed plastic nonsense. Word on the street was they got their asses handed to them over that. It is just a rumor but I cold see it happening.

I don’t normally comment, but its interesting to see that was not an isolated FUBAR.

Any plans for them to open an adjacent weapons cleaning kiosk?

this guy…………..

the washing process is sometimes detremental to the effectivness of some items of equipment. So Joe will do bad things to Pass CIF standards, in turn destroying coatings, laminates etc. on his or her kit.

CIF s dont care as long as irt is clean.. so the next Soldier is issued a rain coat with out a water repelent finish, or a sleeping bag with compromised insulation.

It would be interesting to see how these folks cleaning process (Spec.) is a big savings to the user, and Goverment.

They’ve been doing it for a couple of years for the SPEAR program. In fact, they are currently working with the Army to evaluate how their green process affects ballistic inserts.

^^^^^……(starts slow clap)………

You thought that no starch, patch sewing or boot polish would save you cash. MUUUWWAAHHH! Someone has figured out how to be in bed with CIF and BAM! BOHICA to the wallet.