The Düsseldorf-based technology group Rheinmetall is expanding its portfolio with an acquisition in the field of uncrewed systems. Rheinmetall has now signed a contract in Zagreb to buy a majority stake of Croatian uncrewed ground system solution provider DOK-ING. Rheinmetall is acquiring 51% of the company, which was founded in 1991, Vjekoslav Majeti?, the founder and previous sole owner of the company, will retain the remaining shares (49%). Rheinmetall’s entry into DOK-ING is subject to approval by the relevant regulatory authorities. Both parties have agreed not to disclose the purchase price.

Following the completion of the transaction, DOK-ING will continue to operate from its headquarters in Zagreb, with the existing management team remaining in place to ensure strategic continuity and operational stability, an arrangement aligned with and endorsed by Rheinmetall.

In the presence of Ivan Anuši?, Croatia’s Deputy Prime Minister and Minister of Defence, the contract was signed today by Vjekoslav Majeti?, founder of DOK-ING and the CEO of Rheinmetall’s Vehicle Systems Europe division, Dr Björn Bernhard.

Dr Björn Bernhard said, “The combination of Rheinmetall’s expertise in tactical vehicles and DOK-ING’s capabilities in uncrewed systems will create a strong market position for us with considerable potential for the future. At the same time, we are establishing a foothold in Croatia, being an EU and NATO member, and we will be gaining access to this highly interesting customer country”.

“Our competence centre for uncrewed and autonomous systems for military applications is now being established in Croatia. With this new set-up, it is our goal to obtain a strong market position in the segment of uncrewed combat support and armoured military engineering systems. We do see the potential for significant growth in this market and believe that we are entering the global market at the proper time with our new products. This is underlined by ongoing and planned procurement projects in many other countries”, as Dr Björn Bernhard continues.

DOK-ING has a strong market position in uncrewed solutions for mine clearance and operations in hazardous and high-risk environments in civil and military domain. Since its foundation, the company has delivered around 500 platforms to customers in over 40 countries. At present, DOK-ING’s mine clearance solutions are highly effective in Ukraine.

Already in October of 2024, the two companies agreed on a partnership, which initially focussed on jointly developing uncrewed ground systems for mobility, countermobility (mine clearing and laying) and combat support operations. A notable aspect of the partnership between Rheinmetall and DOK-ING is its entirely European origin and value creation.

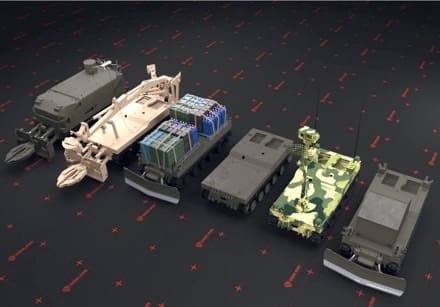

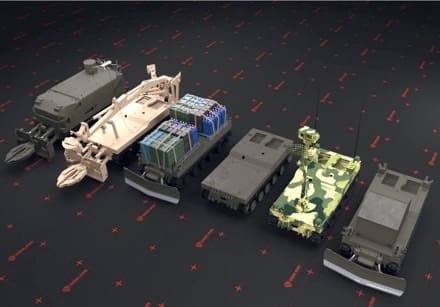

These activities are based on DOK-ING’s newly developed Komodo, a modular heavy duty hybrid uncrewed platform, which has a payload capacity of over 8,5 tonnes. Rheinmetall is contributing with various capability modules and equipment kits, including those for direct and indirect fire, mine clearing and laying, autonomous capability and logistics.

Dr Björn Bernhard said: “DOK-ING and Rheinmetall are two leading European suppliers in their very special field, and by joining forces, we can realise challenging projects. Together, we are aiming at setting new standards and hence, pave the way for uncrewed ground systems (UGS) which are ready for mass production and deployment”.

Vjekoslav Majeti?, founder of DOK-ING said: “This partnership with Rheinmetall marks the next phase in DOK-ING’s development. Over more than three decades, we have built strong technological capabilities and established a solid international presence in demanding markets. We have now reached a stage where further value creation and production scaling require a partner with substantial industrial capacity, system integration expertise and global market access“.

„DOK-ING’s development, engineering excellence and core competencies will remain in Croatia. By joining forces with Rheinmetall, we are creating the conditions to expand production capacity, accelerate the development of next-generation uncrewed specialised systems, and strengthen our long-term competitiveness“, Majeti? added. „This strategic step positions DOK-ING for sustainable growth and reinforces Croatia’s role within the European defence and technology landscape.”

In the new constellation, DOK-ING and Rheinmetall plan to develop a variety of solutions for combat and combat support operations. This includes a project for an uncrewed armed support system (known as ‘Wingman’) to be used with battle tanks and infantry fighting vehicles for reconnaissance and fire support purposes. These systems will also be used alongside existing Rheinmetall products, such as the Panther KF51 Main Battle Tank, the Büffel/Buffalo recovery tank, and the Kodiak armoured engineer vehicle.

Rheinmetall AG is an integrated technology group, with its headquarters in Düsseldorf. Founded in 1889, it is a leading international systems house for the defence industry and operates within land, air, sea and space domains. A focus on sustainability is an integral part of Rheinmetall’s strategy. With around 44,000 employees at about 180 sites worldwide, the company has been listed on the DAX 40 since March 2023 and generated sales of €9.8 billion in the 2024 financial year.

DOK-ING is a technology-driven company specialising in the development and manufacture of advanced uncrewed systems designed for operations in hazardous and high-risk environments. Its core portfolio includes remotely operated and progressively autonomous platforms supporting humanitarian and military demining, military engineering operations, CBRN response, and the protection of critical infrastructure. The company’s solutions are based on modular and scalable architectures, enabling rapid mission-specific configuration for mine clearance, IED disposal, route clearance, firefighting, and other complex operational requirements. With a strong commitment to safety, reliability, and operational excellence, DOK-ING delivers field-proven systems that enhance force protection and reduce human exposure to risk, serving armed forces, civil protection authorities, and specialised security operators worldwide.