During the recent SIG NEXT event in New Hampshire SIG announced that they would not only introduce an MCX SPEAR chambered in 6.8×51, but that they are also increasing the types of 277 FURY cartridges as well as offering a 6.8 ammunition for commercial sale.

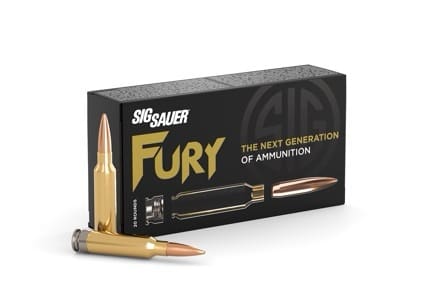

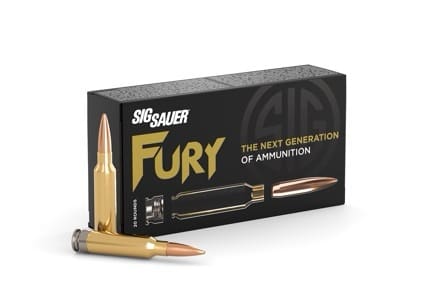

277 FURY / 6.8 x 51mm Ammunition

The cartridge is unlike anything else out there and was developed by SIG Ammunition in 2017 at their plant in Arkansas. The design is 23.5% lighter than the weight of an equivalent energy cartridge (270 WSM) which exceeds the Army’s goal of a 20% weight reduction for the Next Generation Squad Weapon program.

In addition to being lighter, the case is also stronger. It features a unique hybrid case design which is made of two components, a brass body and steel head. Combined, you get more strength in the head where you need it, and a malleable case which works very well in the firing cycle. This allows the cartridge to withstand very high pressures, in excess of 80,000 psi, and right along with it, you get very high velocities.

277 FURY is the SAAMI certified equivalent of the US Army’s new 6.8 x 51mm hybrid-cased cartridge developed for NGSW. The commercial 277 FURY ammunition has been around for a while now and incorporates the 150 grain Nosler AccuBond projectile. It’s a boat tail bullet, featuring a polymer tip, copper-alloy jacket with a lead-alloy core and a thick heel. With this cartridge expect 3,000 FPS from a 16” barrel and an additional 30 FPS for every additional inch of barrel.

SIG Ammunition’s new 113 grain 6.8 ball cartridge from SIG is as close as you are going to get to the new XM1188 solid copper projectile ammunition being procured by the US Army for NGSW. It comes off of the same line and it’s produced to the same specs, meaning, you’ll see the same performance. Expect muzzle velocities above 3200 feet per second from a 16” barrel from this hybrid cartridge.

All told, you’ll have access to 6.8×51 hybrid ball in can (460) or crate (920), 277 SIG Fury Venari Hunting 130gr soft point (non hybrid), and 277 FURY hybrid match 155gr OTM as well as the currently available 277 Accubond and 277 ball (non hybrid).

There are a lot of rumors floating around out there about the NGSW program. One of them is that SIG isn’t delivering enough ammunition to the Army. This isn’t true. In fact, the availability of this commercial ammunition is proof that it isn’t so.

6.8 MCX SPEAR

When the Army adopted SIG new ammunition they also adopted two new weapons to fire it, the XM250 Automatic Rifle which is actually a belt-fed machine gun replacement for the current Squad Automatic Weapon and the XM7 Rifle which will replace the M4 carbine in units like the Infantry and Cav Scouts across the service.

Along with the commercial 277 FURY ammunition, the bolt action SIG CROSS has been available for a couple of years. In addition, you’ll now also have a semi-auto rifle chambered in 277 FURY. They are expanding the caliber selection of the popular MCX SPEAR platform to include 6.8 / 277 FURY in addition to the currently available .308 and 6.5 Creedmoor.

Just like the XM7 version, the 6.8 MCX SPEAR features a 13.3″ barrel so it’s an SBR. However, they are planning to introduce a pistol version now that stabilizing braces are back on the menu as well as a standalone upper for those who already own an MCX SPEAR rifle in .308. As with the 6.8 ammunition, the 6.8 MCX SPEAR is as close as you are going to get to NGSW without joining the Army and being assigned to one of the close combat units receiving the new gear.

Look for these new options soon.

www.sigsauer.com