Marine Corps Base Quantico, Va. —

Although Marines have never defined themselves by their equipment, maintaining readiness in any clime and place—from the icy reaches of the Arctic to the steamy jungles of the Indo-Pacific—means ensuring that all Marines, whether on the frontlines or providing critical support from behind the scenes, are equipped with the right gear to accomplish the mission whenever they are called to serve.

To better support pregnant Marine Corps officers, Marine Corps Systems Command, in partnership with Marine Force Storage Command’s Consolidated Storage Program (CSP), is expanding the Maternity Uniform Pilot Program (MUPP) from Quantico to include East Coast bases such as Camp Lejeune, New River, Cherry Point, Beaufort, and Albany.

This expansion—driven in response to feedback from Marines across the Corps– ensures easier access to maternity uniforms, promoting both comfort and readiness, while also addressing equity between enlisted Marines and officers.

Enlisted Marines receive a one-time issue of maternity uniforms, while officers have been required to cover the full cost, which can run up to $500. The MUPP allows the Corps to issue and recover maternity uniforms for officers at no cost, easing the financial burden and ensuring all Marines are equipped for duty.

“There are Marine officers across the Corps who will need maternity uniforms, so expanding this program to the East Coast is essential,” said Ana Ayala-Spivey, CSP East Coast Regional Project Officer. “I stressed to the MARCORSYSCOM team that it’s our responsibility to ensure we capture valuable data and feedback from as many Marines as possible. Limiting the program to Quantico wasn’t enough. Expanding it allows us to gather the insights we need while better supporting our officers in maintaining readiness and comfort during pregnancy.”

Since March 2021, the program has already seen significant success at Quantico, where it was first introduced, providing essential support to pregnant officers stationed there.

“I’ve been pregnant twice during my time as a Marine officer, but only had access to the Maternity Uniform Pilot Program once,” recalled Maj. Desiree K. Sanchez, assistant chief of staff (G-4) at Marine Corps Training and Education Command. “The first time, I had to purchase all of my uniforms out of pocket because the program didn’t exist. By the second time I was pregnant, the Corps had made significant improvements, adding adjustable tabs to the shirts and smock for a better fit. Instead of having to buy the updated uniforms, I was able to borrow them here in Quantico through the program, saving me from the expense of buying new items again.”

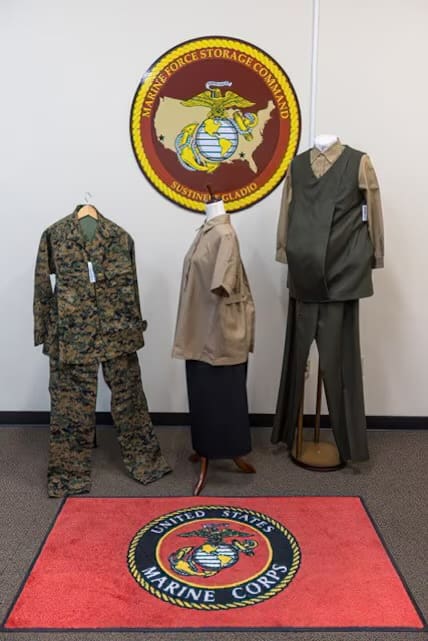

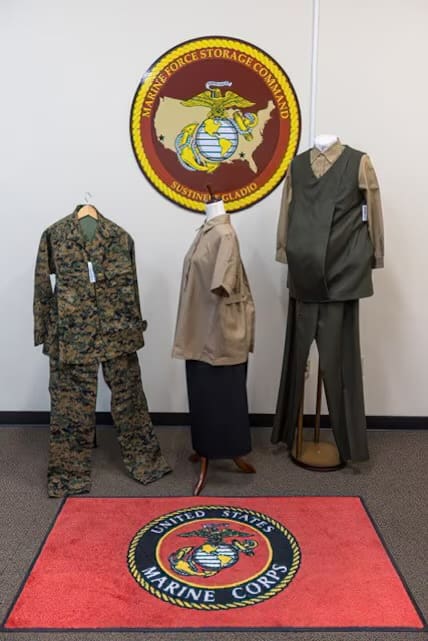

The program provides pregnant Marines with a full set of essential maternity uniforms, including three sets of MARPAT work uniforms (blouses and trousers), one green tunic, two short-sleeve and two long-sleeve service blouses, two service skirts, one pair of service slacks, one blue dress skirt, one pair of blue dress slacks, and three sets of service tapes.

The East Coast expansion improves accessibility for pregnant Marine officers by providing timely access to essential maternity uniforms at key installations, all without adding any extra financial burden to the taxpayer. Besides the financial benefit, this program also addresses the practical challenges pregnant officers have long faced in uniform availability and consistency.

According to Maj. Sanchez, “I was serving at Headquarters Marine Corps as the aide to General Glenn M. Walters, the ACMC at the time, during my first pregnancy. I often found myself discussing the challenges we faced as pregnant officers—having to pay out of pocket for uniforms that were not always available. There were countless times when I couldn’t match my boss in uniform because certain maternity options simply didn’t exist in the Marine Corps inventory. It was a constant reminder of the gaps we had to navigate.”

Ultimately, the MUPP’s expansion to include key East Coast bases serves as a strong signal of the team’s commitment to acting on feedback from the fleet– a critical component of Force Design, the Corps’ strategic blueprint for modernization.

“We actively use the [Interactive Customer Evaluation] program to gather feedback from Marines on improvements or concerns with the maternity uniform,” said Ayala-Spivey. “This input is essential for shaping decisions that affect the readiness and capability of the Future Force. As part of our commitment to Force Design, it’s crucial we recognize that Marines in a maternity status are a vital component of that future. Ensuring they have the right equipment supports both immediate operational readiness and long-term sustainability of the force.”

To participate in the program, pregnant officers can schedule an appointment with East Coast CSP personnel via email or phone, using the POC information available on the CSP site. Participants will then visit their respective Individual Issue Facility (IIF) to try on uniforms based on their pre-pregnancy sizing, with adjustments made as needed throughout the course of their pregnancy.

Although the expansion focuses on East Coast installations, pregnant Marines from other locations—including those OCONUS– can participate by contacting ana.ayala.civ@usmc.mil or william.j.wrightington.civ@usmc.mil.

By Johannes Schmidt, MCSC Office of Public Affairs and Communication | Marine Corps Systems Command