New materials really are at the core of providing truly new garments. Let’s face it, you can only make a combat shirt but so many ways. But when you add in a new fabric, possibilities become realities.

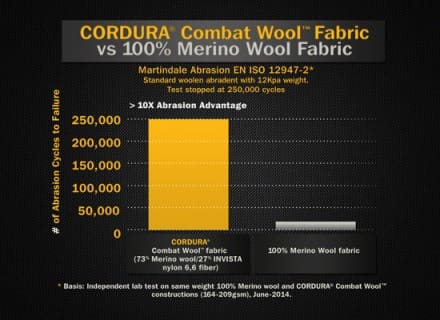

The same CORDURA brand that you know for making texturized nylon used in most of your field equipment has come out with a new fabric called Combat Wool. It consists of a blend of merino wool and nylon, intended to combine the comfort and durability of its base parts. CORDURA claims, through an independent study, that Combat Wool offers 10x better abrasion resistance, 2.1x better tensile resistance, and 1.4x better tear resistance when compared to 100% merino wool fabrics while maintaining the same look and feel. It is currently available in a variety of styles and constructions, including base/mid-layer knits, double face wovens, canvas, ripstop, twills, dobby, and stretch woven fabrics.

www.cordura.com/en/fabric-technology/wool-fabric.html

Tags: Cordura

Ooh this sounds nice! I am however pretty curious about it’s other properties which make wool a great choice, as in thermal properties, heating when wet, how long it takes to dry and if it’s still naturally FR.

Dont worry, only Vikings care for that 😉

Um.. Yea exactly.

So why are non-vikings excited for a highly abrasion resistant wool then?

natural material breathes better and is fr and it kills odor

If they are thinking for combat shirt, its a different story.

Possibly dumb question….but does this also imply greater flame resistance than previous Cordura Nylon products?

I’m glad they’re not being sheepish about making this announcement.

heyyyyyyyoooo

I saw what you did there…

Okay TAD…let’s see some stuff in this. 😉 Very interested in this material.

I hope outfitters make daily wear items with this. I’d like a me durable merino wool cable knit sweater for the office and afterwards. That maybe has a shoulder pocket.

whats old is new again …….. im starting to see wool making a come back in the military which i find kind of interesting…

Wear a 6 month old tech synthetic (where the odor-protective properties have worn off) for 2 days and it will pick up a stink that never washes out.

I have 5-year-old merinos that I wore for weeks at a time downrange that I can wear under a business suit from SLC to Buffalo.

Surprised–and kinda bummed–that there isn’t a sand-colored Merino t-shirt for wear under the ACU…

https://soldiersystems.net/2012/05/07/icebreaker-t-shirt-sale-at-mre/

Icebreaker used to make them, and Mission Ready Equipment sold them (link above). However, it seems they may be extinct now. I have about 5 or 6 I picked up 2.5 years ago, still going strong.

I got a few of those too (LS and SS).

They look fine under OCP but don’t cut it in garrison under a UCP uniform.

We may well be ahead of the curve when the boots and t-shirts change. Hopefully there are other players when that happens.

For the longest time, I only used the clothing items that I was issued. After a long night where my feet got uncomfortably cold I took the leap to wool and have never looked back. Since then, I have yet to have an issue with having cold toes, getting blisters or even smelling after stinking so much. The one thing, like “straps” mentioned, that I would like to find is a proper colored tan shirt in merino. Maybe someday.

It’s been happening for awhile. It’s about numbers at this point.

let me guess uncle sam as always is trying to go cheap or are we talking about the cost of manufacturing

It’s having enough Berry compliant wool.

well ya that could be an issue

Merino is really where it’s at: Icebreaker has been using a similar technology as of this year for some of their garments to limited success. This seems to be much, much more sturdy.

On top of being moisture-wicking and breatheable, Merino is odor-resistant and FR like others have said. I’d love to see some shirts made of this stuff because lightweight merino gets holes in it after relatively light use…

Yes, hopefully it will solve the main problem with Merino (durability) without losing any of the many advantages. If so, would make a great material for combat shirts(torso), socks, gloves, hats, and of course base layers.

You lose on of the greatest properties of wool…being FR.

Not very combat ready…

Yup.

Wool/aramid?

Who wears merino wool for its abrasive resistance. Ill tell you…..no one. They wear it as a base layer for its qualities in odor resistance and warmth and cooling capability. I don’t know what Cordura is trying to accomplish here.

Exactly. Ive used these merino/synthetic blends (one example is ulfrotte) and they are inferior to 100% merino. Merino is for baselayers, If you do like merino outerwear then take a look at mufflon who make the fabric & clothing in germany out of boiled merino (420g/m2) or boiled new wool (700g/m2). That stuff is as rugged as it comes. I have the mufflon luke vest which is my mid layer.

one of my favorite merino garments has a high nylon content (36%) and it blocks wind fantastically and has held up well. Should dry much faster then straight merino as well.

hoping for both woven and knit fabrics, I’d use it for both parts of a combat shirt, and I’d wear the crap out of some woven pants.

I use Merino for SAR and general outdoor stuff constantly. I LOVE it. Fantastic odor management (weeks without a real wash? not an issue!), great comfort, great everything. Baselayers (top, bottom, socks), glove lines and sometimes midlayers (that end up as outerlayers when I remove my shell).

But durability is indeed an issue. It easily gets holes caused by belts or snags. When used as glove liners inside Gore-Tex glove shells, they get holes quickly. So I do appreciate any initiative that will help merino be more durable.

But at what cost? Will this blend reduce the advantages of Merino – things that make it such a fantastic product?