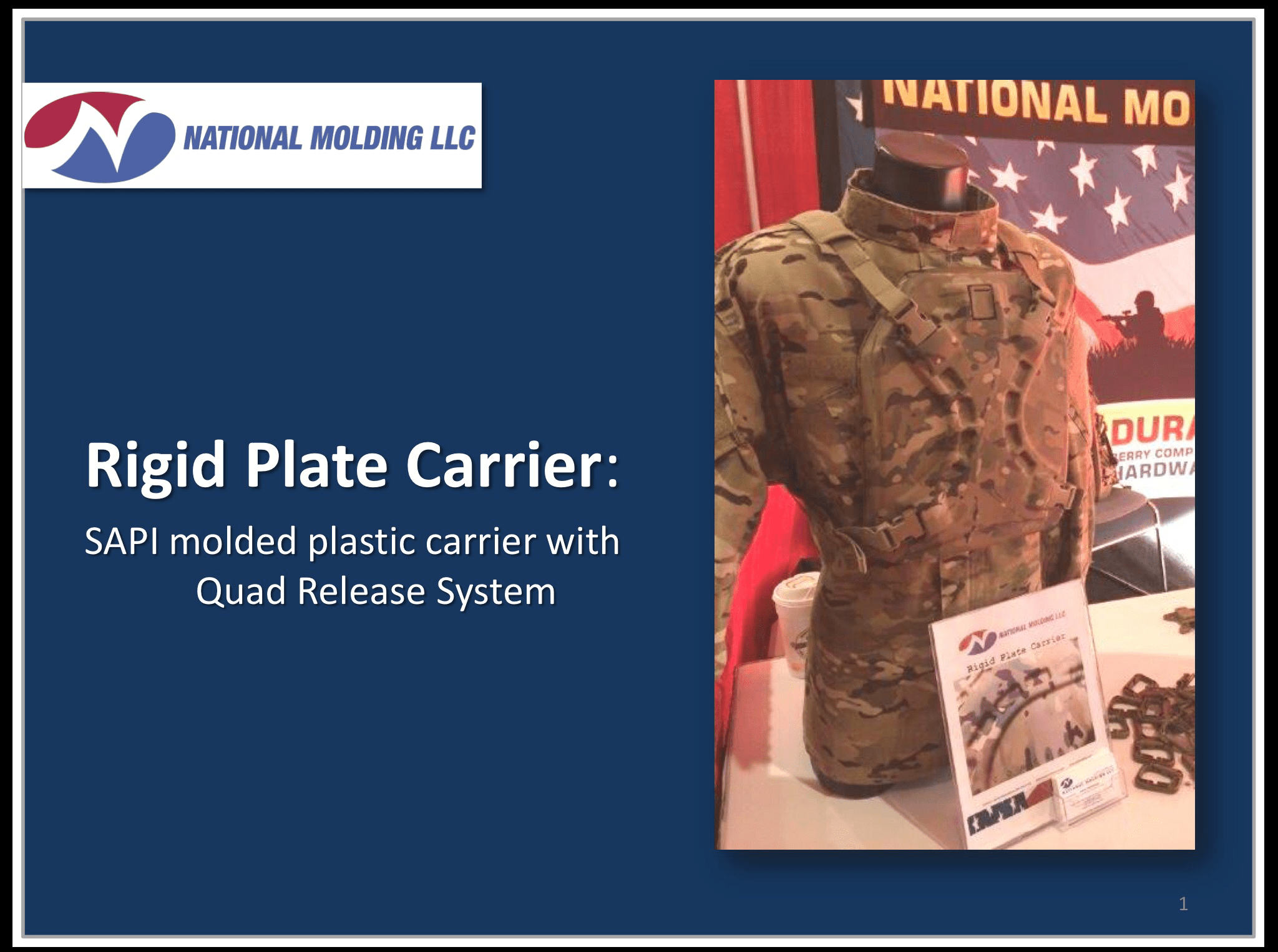

We first showed you National Molding’s Rigid Plate Carrier during last year’s Modern Day Marine Expo. Since then, they’ve continued to refine their design and begun to garner some interest in the technology.

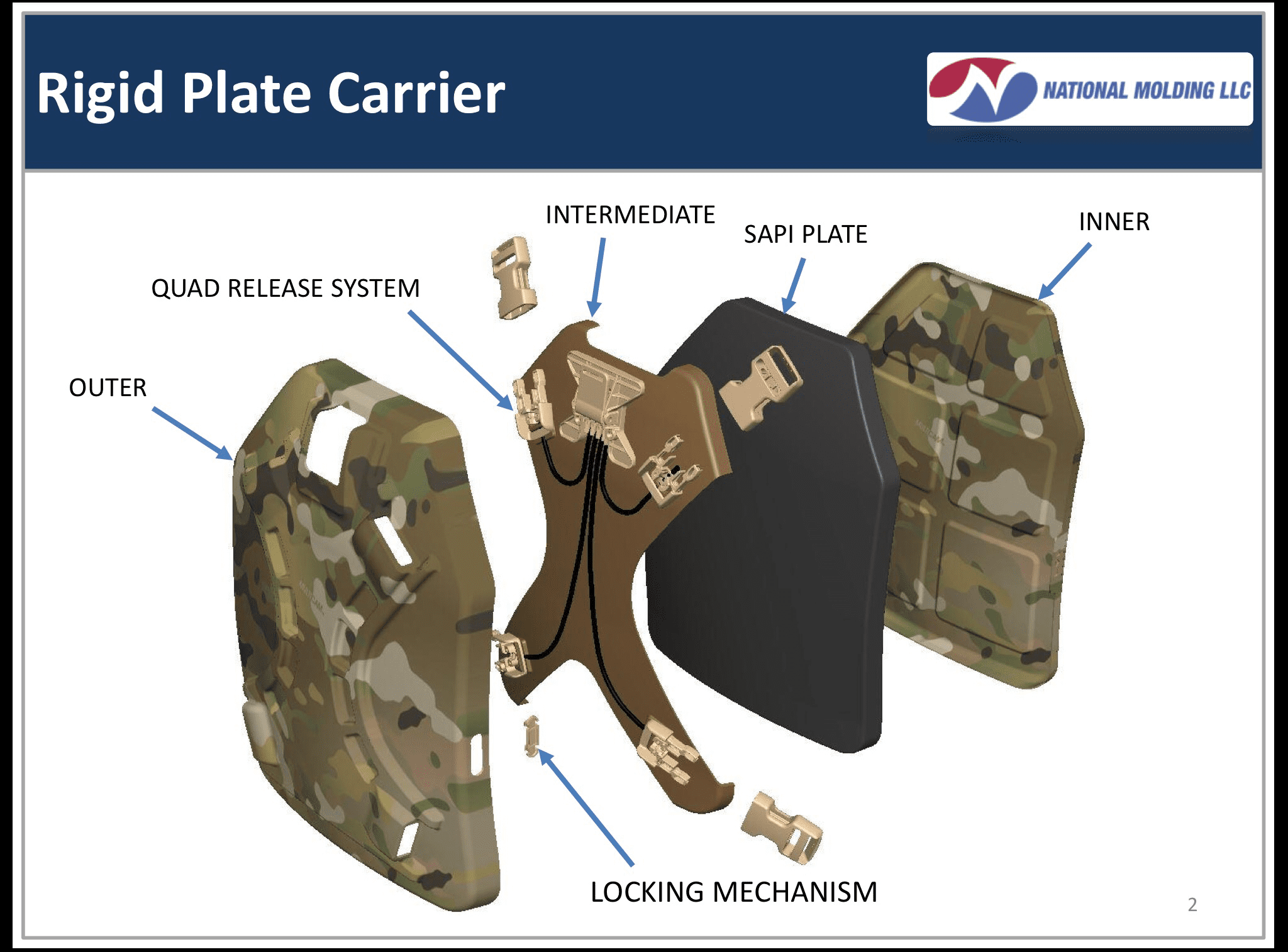

Below, you can see the components of the RPC which encapsulates the plate. The plate can be removed for inspection or replacement. You can also see that the RPC incorporates National Molding’s Quad Release.

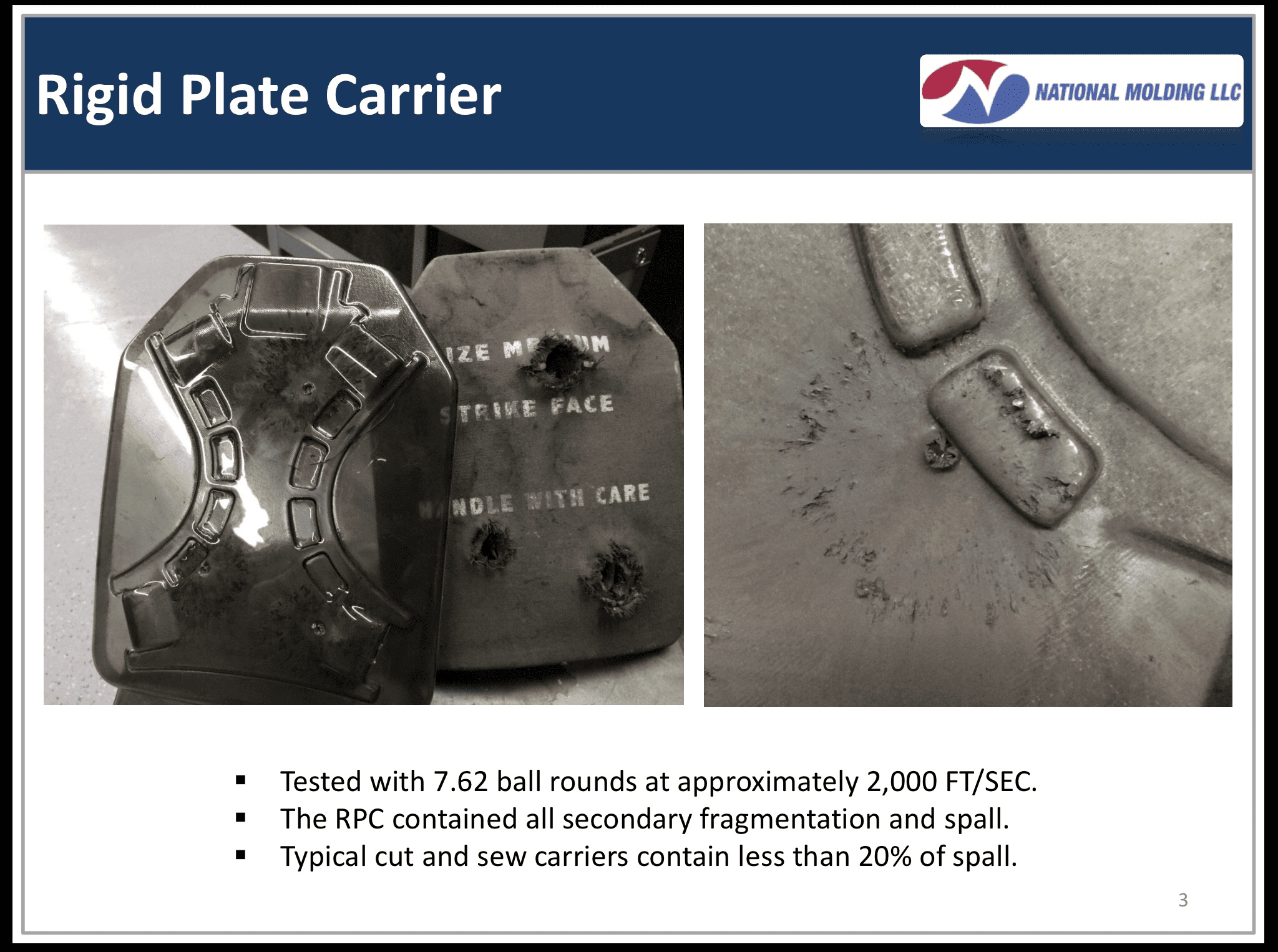

Finally, this photo depicts a translucent RPC panel, used in ballistic testing. They have demonstrated rather promising containment of projectile spall.

Tags: National Molding

Coat the outside in a FROGS low IR signature velcro to allow for attachment of chest rigs and unit patches and they will sell thousands.

* FR

looks like my trash can lid. Im sure its just as loud too.

This Plate Carrier is awesome! I have seen one close up!

I fail to see the value proposition here. Unless you use plates that spall like crazy, then you might want it…

most SAPI plates that are military issued have spall issues… the cut and sew carrier captures some… this captures all of it… and it keeps the integrity of the plate in tack… most plates end up cracked from impacts other than ballistic. dropped on the floor and in and out of vehicles bangs them up pretty good… this helps keep them in one piece.

Looks intersting. Does anyone had a chance to play with it?

Uh….what happens if the quick release system gets hit or one of the buckles gets hit…the thing goes and falls off your chest?

That’s the same buckle as on the IOTV.

nope… the others will release when the trigger is pulled and the damaged cable will not… the cable damage will not trigger the buckle

The armor encasements strike me as a solution in search of a problem.

Any chance that release mechanism should sit on 5x PALS-mount pads and be marketed as a retrofit upgrade? That’s the coolest thing I’ve seen since Tubes.

tubes are definitely cool but they simply take to the place of a side release buckle… single point release… on top of that they are difficult to re assemble under load… but definitely cool!

Looks like a solution to a problem that doesn’t exist… I really don’t understand what kind of warfighter would need a plate but no load carrying capability.

Your average dude carries a lot. Hydration, communications, signalling devices, ammunition, tools, etc. These requirements are probably never going to change for the foreseeable future. The load has been distilled we can make things incrementally lighter, but these things take time. The need for MOLLE/PALs/some sort of attachment system is not going to disappear.

I’m curious why you think there’s no way to carry a load with this?

aside from the fact you can attach additional load carriage to the carrier, what would stop a person from throwing a chest rig, LBE, battle belt, and/or pack on? MOLLE is great and all but it’s not the only way to bring more stuff to the dance.

While you are right, you can throw on a chest rig/lbe/battle belt etc… but now you are just adding more weight. I’m old school military and ounces equal pounds. Not going to carry/wear something bc it looks cool to just bulk up even more. The same train of thought applies to people who buy MLOK rails to just put on a picatinny rail adapter. Just buy a pic rail and call it a day….

And with things like hypalon chest rigs you can add all of those pouches with almost no weight disadvantage, but you have the advantage of being modular and the option to carry that same equipment without the armor.

In any case it’s a moot point because you can attach load carriage directly to the carrier OR put those systems over top.

the load carriage cover for both front and back will be unveiled at AUSA… a basic molle platform or mission specific cavers can be built. will give load bearing capability without going over board …

Depending on how much this Nat’l Molding Plate carrier, weighs – this could be quite a boon for the average or above-average War-fighter. Think various ‘carriage systems’ could be built or adapted for this rig at a later date. In spite of the detractors, think this is a really cool concept that could go well beyond the ‘proof-of-concept’ distance and become a very popular standardized plate-carrier rig in many Spec-War communities… Think my only concern would be comfort. Wearing this rig fourteen/fifteen hours a day, it would have to be comfortable and ergonomic.

Think it would also be a good idea to have the latitude of fastening a cummerbund for side-plate carriers to this Carrier. Although this plate carrier has the purported ability to absorb a hundred percent of the incidental spall that will almost invariably result from a bullet strike, I have to wonder about the carriers ability to help an Operator survive the substantial obverse deformation of several 7.62 bullet strikes(kinetic). Regardless, this seems like a great idea that’s definitely is worthy of further evolutionary development. Great idea, National Molding!! Thank you for this post, SSD!!!

There will be several load carriage covers from mission specific to a basic Molle platform… The one big feature that is often overlooked it the fact that the plate is protected from drops and other accidental impacts. Most damaged plates that are turned back in are from Non ballistic or frag impacts but rather general physical abuse… so this system should help to keep the plates in good shape.