By Mathuel Browne, MCSC Office of Public Affairs and Communication

MARINE CORPS BASE QUANTICO, Va. – The Marine Corps is celebrating a decade of keeping Marines safer on the battlefield with the Mine Resistant Ambush Protected family of vehicles.

In 2006, combatant commanders identified the urgent operational need for an increased number of MRAP vehicles in theater to provide better protection against underbody mines, improvised explosive devices, rocket-propelled grenades and small arms fire. MRAP vehicles were already in use by the Army and Marine Corps, but in limited numbers and for specialized missions, such as explosive ordnance disposal and other route clearance work. In response, Marine Corps Systems Command established the MRAP Joint Program Office in 2006, to combine the efforts of Marine Corps, Army, Navy and special operations acquisition expertise. The JPO’s mission was to get the maximum number of vehicles to the operating forces in the shortest period of time.

“The object of the program office was to field vehicles to all the services, U.S. Special Operations Command and coalition partners to ensure the same level of troop protection was provided to the entire joint and combined forces,” said retired Marine Corps Brig. Gen. Michael Brogan, Joint Program Executive Officer for the MRAP vehicle program from 2007 to 2011 and a former commander of Marine Corps Systems Command. “The presence of the MRAP also challenged the enemy, since the insurgents had to increase the size of their explosive devices to have any effect on these more survivable vehicles. The larger devices, and longer time it took to implant them, increased the likelihood that our troops would detect an IED before it detonated.”

The MRAP family of vehicles consists of four vehicle categories that incorporate a “V-shaped” hull, armor plating and a raised chassis designed to provide protection against the three primary kill mechanisms of mines and IEDs: fragmentation, blast overpressure and acceleration.

The Category I MRAP Mine Resistant Utility Vehicle is the smallest version, weighing 7-15 tons, is primarily intended for operations in urban combat environments and can carry up to seven people.

The Category II MRAP Joint Explosive Ordnance Disposal Rapid Response Vehicle, weighing 15-25 tons, is a multi-mission platform used to lead convoys, transport troops, ambulances and utility vehicles. They carry up to 10 people.

The Category III MRAP is designed for mine/IED clearing operations and explosive ordnance disposal. It is the largest of the MRAP family, weighing 22.5 tons and is capable of carrying up to 13 people.

The MRAP-All Terrain Vehicle is the newest variant in the MRAP family. It offers the same level of armored protection as previous MRAPs, but with much better mobility. In Afghanistan, baseline MRAPs struggled with the rocky terrain, creating a need for a more mobile vehicle. The M-ATV is designed to operate in the most extreme conditions which allowed it to maneuver over rubble and rocks. It supports a crew of five, including a gunner and can travel at speeds up to 65 mph with a range of 320 miles.

In 2007, MCSC’s Command Senior Enlisted Leader Sgt. Maj. Gary Smith served as first sergeant for 1st Battalion, 10th Marines in Iraq’s Al Anbar province. He said he remembers his Marines’ excitement when the battalion received their first MRAPs.

“At the time, it was our responsibility to take numerous convoys—up to three to four hours— to various locations to deliver supplies,” Smith said. “Riding in MRAPs gave us the confidence that we did not have in our previous vehicles, that we were safe and able to do our jobs effectively. For our government to jump through so many hoops to get the vehicles to us so quickly improved morale throughout the organization, because the vehicles increased our troop’s survivability.”

The MRAP JPO was able to acquire and field the vehicles at an accelerated rate because then Secretary of Defense Robert Gates established the program as the highest priority Defense Department acquisition program. All options to accelerate the production and fielding of MRAPs were identified, assessed and applied where feasible.

“Originally, we did not know if we could create the vehicles in the numbers we needed,” said Paul Mann, joint program manager for the MRAP JPO from 2006 to 2010. “However, we had permission from Congress to take the risk and at least try.”

In 2006, MCSC was designated as DOD’s lead procuring agency for the MRAP. To fill the urgent need, the command awarded nine separate indefinite delivery, indefinite quantity contracts for 36 initial test vehicles.

“We had confidence that the automotive components were commercially available and functional, but we perceived significant risk in the survivability performance,” said Mann. “So we mitigated the risk by challenging manufacturers to develop and deliver their best MRAP prototype with a sense of urgency and we drove the vehicles and tested their survivability. If they met our requirements, we set out to buy as many as they could produce as fast as possible.”

The contracts required the initial vehicles to be produced within 60 days. In less than the two months given, five vendors produced vehicles that met the joint survivability requirements, production numbers and delivery timelines. Ultimately, seven of the nine companies received low rate initial production orders, and produced a total of 27,774 vehicles under the MRAP JPO.

In 2012, the DOD transitioned the JPO’s responsibilities to the military services and SOCOM. Each service now manages its own fleet of vehicles, with the Marines aligning the MRAP program under Program Executive Office Land Systems in 2013. Today, the DOD continues to use MRAPS for training and with some strategically positioned to meet future contingencies.

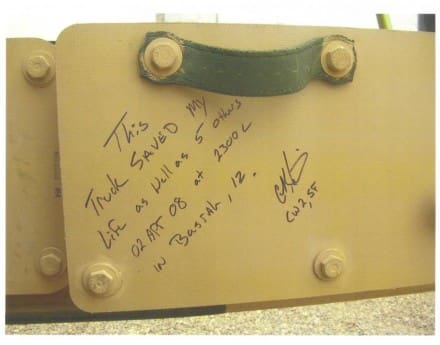

“No recent program has had the impact that MRAP had on the survivability of the force,” Brogan said. “Though we’ll never know exactly how many lives the program touched, we know it did. Acquisition programs come and go, but the contribution of the MRAP program will continue into the future.”

160620-M-IR546-786

The Marine Corps is celebrating a decade of keeping warfighters safer against explosive devices with the Mine Resistant Ambush Protected family of vehicles. MRAP vehicles are designed to provide protection against underbody mines, improvised explosive devices, rocket-propelled grenades and small arms fire. From 2006 to 2012, the MRAP Joint Program Office fielded a total of 27,774 to operating forces in Iraq and Afghanistan. (U.S. Marine Corps photo by Sgt. Lynn Kinney)

The Marine Corps is celebrating a decade of saving countless lives on the battlefield against underbody mines, improvised explosive devices, rocket-propelled grenades and small arms fire with Mine Resistant Ambush Protected family of vehicles. The MRAP Joint Program Office mission was to get the maximum number of vehicles to the operating forces in the shortest period of time. From 2006 to 2012, the JPO fielded a total of 27,774 to operating forces in Iraq and Afghanistan. (U.S. Army courtesy photo)

The MRAP and MATV saved our collective asses on many occasions. Would not have wanted to roll over what we did in a HMMWV, uparmored or not.

Tens of billions spent to defeat/defend against improvised mines, A tactical weapon with strategic impact.

Loved the M-Atv & the Cougar series, the Max-pro was a “little” too top heavy (but, I’ll ride one any day) and the Caiman was pretty freaking good too…

Thanks to all who made them, engineered them and got them to us!