Othermaterials has developed a new fabric technology which combines different materials, including polyolefin, to offer variable insulation.

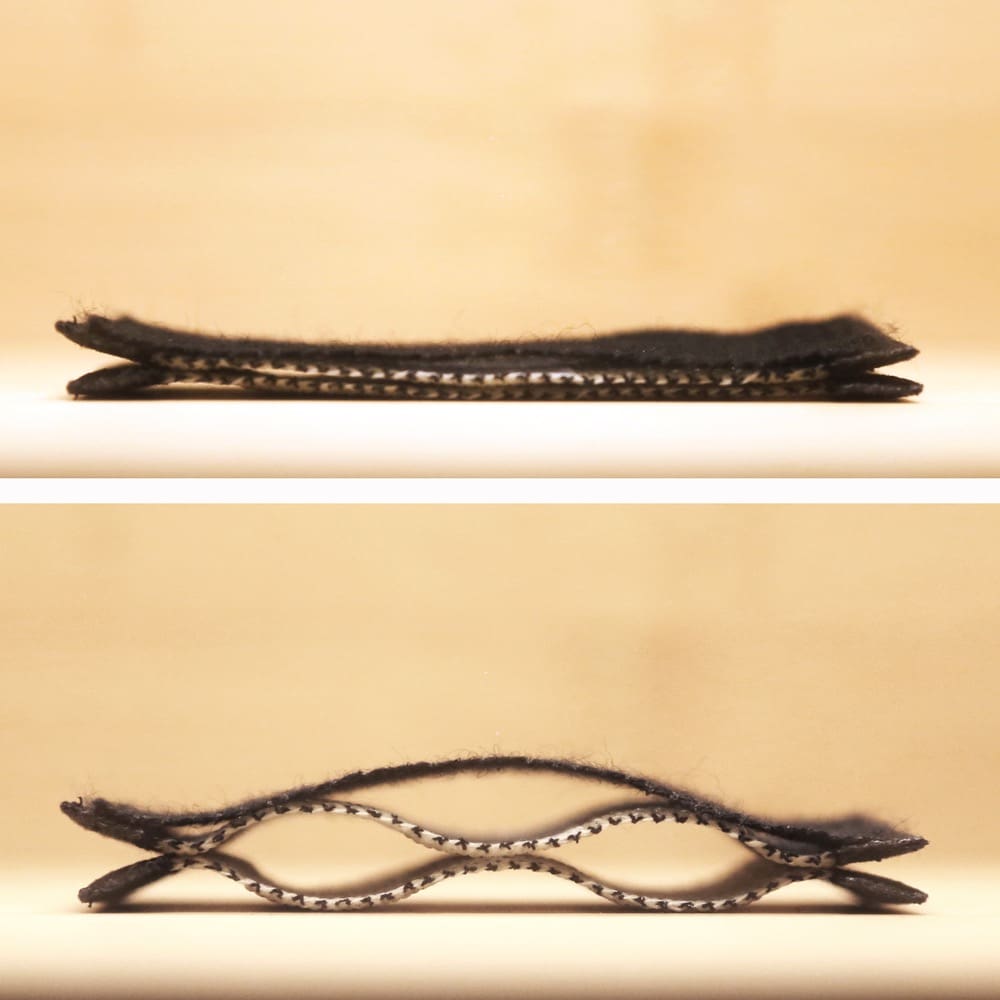

Previous attempts at so-called phase change materials have concentrated on regulating the size of pores in the fabric relative to temperature. But with Othermaterials, they use a “biomorph actuator” which relies on combining materials that react differently depending on the temperature. In this case, when stacked, they produce a curve; the lower the temperature, the more the curve. This can used as a structure to create air pockets for the purpose of insulation. According to the company, early prototypes have demonstrated a more than doubling of the material’s thickness with a temperature change of 10 Deg C.

Othermaterials developed this technology under an award from ARPA-e and is concentrating on convincing business owners of the material’s worth in regards to savings in hearing and cooling costs. However, I’m much more interested in its potential for outdoor and military clothing. The obvious application is outerwear, but it may also work for sleep systems as well as for protecting patients under field medical care.

Learn more at materialcomforts.com.

Tags: Othermaterials

This is extremely interesting to me since it is a passive system. We already have products from companies like Klymit which allow you to inflate your jacket for insulation, but the passive nature of this setup is unique.

What is the durability of a fabric which is designed to fluctuate shape like this? Do you think there would be issues caused by a user’s body heat keeping the fabric from adjusting shape?

This is incredible!

However, I’m wondering how the inner layers would behave after they gradually get warmer under body head & moisture. Wouldn’t it auto decrease the thickness of the material, thus reducing the barrier’s width?

Probably, but with the right development this could be tuned so that it always provides the right amount of insulation – when you start heating up, it decreases its effectiveness until an equilibrium is established in a comfortable range.

This really could be a game changer with the right development.

“This really could be a game changer with the right development.”

You’re not kidding. No more insulation layers, just one layer that expands or contracts depending on outside temperature and activity level.

All you would need to add is a water proof.

Reminds me of Nitinol.

I love Nitinol. I still have a bunch of wires around the office that I play with.

If this stuff is fairly resistant to “body juices”,like sweat and skin oils, it will be excellent. I understand that Kevlar deteriorates after prolonged contact with these substances.