The Problem:

The Silencerco Octane/Omega 9K piston and fixed mounts are not compatible with conventional tools and cannot be adequately tightened or loosened by hand. This is also true about the Dead Air Wolf-9SD and Ghost suppressors. In the case of the 13.5mmX1LH fixed and piston mounts, the barrel thread is left-handed and the suppressor body attaches to the mount with a right-hand thread. Rocksett can be used to solve this, but that makes frequent changing of the different mounts a challenge.

I recommend against doing a 3-lug mount arrangement, as the mechanism takes up blast chamber volume, which makes the suppressor considerably louder than with a direct-thread mount, which is what I recommend for the MPX. However, people usually say they use a 3-lug to prevent loosening of the suppressor from the weapon, which can happen with a direct-thread mount if adequate torque is not applied.

I would only use the piston system for pistols and not use a piston with a fixed barrel spacer on an MPX, as this arrangement is also louder than a direct thread mount, but you have no choice but to use a piston mount on a pistol.

The Solution:

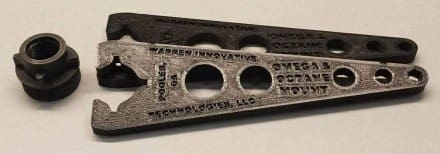

I have 3D modeled and 3D printed a wrench that interfaces with the Octane/Omega 9K direct thread/piston mounts. Silencerco does not make a wrench for these. I also now have one for the Dead Air Wolf-9SD and Ghost suppressors. My wrench is a high-strength PLA polymer material that will break if way too much torque is applied, but if you torque it on with the wrench without a lot of Rocksett, it should torque back off without problems (a very small amount of Rocksett is fine). This wrench is critical for torqueing to the left onto the barrel and then for isolating the mount from the right-hand torque applied to install the suppressor body to the mount.

Easily transitioning between piston and fixed mounts is now possible for the Octane/Omega 9K.

For ordering details, visit facebook.com

Strange, why don’t you just laser cut it in carbon steel?

I didn’t make it out of steel because I didn’t want to damage the finish on the mounts. I looked into laser cutting aluminum but the expert to whom I spoke about it said the small wrench features would cause heat overloading and cause bad results from melting.

The 3D printed product prevents finish damage while allowing adequate torquing for installation and removal. It also allows embedded text without additional laser engraving.

Where does one insert a torque wrench?

Since the suppressor mounts for which these wrenches were designed were apparently intended to be hand-tightened, as no tools were provided by the manufacturers, our tools were designed to impart more torque than bare hands can provide while at the same time not damaging the mount’s finish. Interfacing with a torque wrench was not considered in its design.