Yesterday, I spoke with Scott Jones, the founder of Beyond Clothing who now owns Further Designs. He shared an incredible story with me.

The news of the day remains the COVID-19 pandemic. As scary as it might be, it is awesome to see Americans pivoting their efforts to counter this threat to our health.

The project is home sewer manufacture of filtered masks for use by those who have given up their N95 masks for use by higher risk groups. They’ve created a Facebook Group. Although it was founded by folks in Bellingham, Washington, they encourage others to join and collaborate.

Here is Scott’s story:

I was contacted on Friday afternoon by a friend who is a nurse at a local hospital. She was on the verge of tears fearing that soon she, and her peers, would not have access to any face protection while providing medical care to patients. We are only 90 miles, from Seattle, WA.

I was not behind the idea of simply creating cotton masks, but once the idea of a replaceable micron filter came up, I was on board.

Might as well make em look good, right?

Over the last 48 hours, I have worked with a team of local doctors and nurses, engineers, and others to create the Frontline Mask. As I did at Beyond, I like to be able to create as much versatility in my designs and production as possible. Especially in a dynamic world where items disappear from stores and online overnight. I couldn’t rely on elastic, or a certain fabric, or a certain filter. It had to be able to be ‘plug and play’ by the user, and the mask had to be able to handle the changes.

The mask in its current state, is made of 2 layers of tight weave cotton, with a slit on the face side, for the placement of a filter, that fills the entire mask. Filters such as vacuum bags, industrial filter fabric, hepa filters or the like will be able to be chosen, cut in the field and inserted. The cotton mask will be able to handle the changes to the filter requirements. Although Covid-19 is incredibly small, the transmission occurs on large water droplets that are far easier to stop. Although hospitals and doctors offices are not yet allowing this type of mask, we sadly feel that they will need to soon. Even the CDC has mentioned this regarding bandanas.

We also feel that the FrontLine mask will help those who have generously given up their own masks to more at risk medical professionals; dentists, PT, clinic nurses, soldiers, and senior care centers.

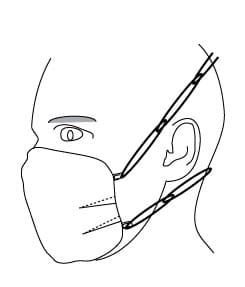

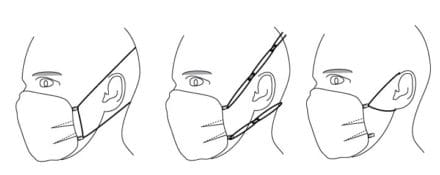

Attachment was also a challenge. To make the mask easily made world wide, but as safe as possible, the attachment to the face had to be dynamic and come with multiple solutions.

Different means of attachment.

The one I find to be most comfortable are daisy chained rubber bands applied to built in anchors in the mask. The nose piece is malleable farm wire, or clothes hanger wire.

The solution is comfortable, air tight around the face, able to go over a N95 mask, and able to handle any filters available.

The Version 1 spec package, patterns and instructional videos are available at fb.com/frontlinemasks or furtherdesigns.com/frontlinemasks and will be continuously enhanced as feedback comes in. We’ve received updates and recommendations for filters from around the US, and recommendations will be listed after further vetting.

If anyone in the Soldier Systems sphere has expertise or recommended items please have them contact me at scott@furtherdesigns.com.