When I see a post on social media about “testing” I have to laugh. Taking a product out in the back yard or to a local range and putting a magazine through it isn’t testing. Neither is coming up with some one-off scenario like shooting a helmet with a threat it wasn’t designed for. Those demonstrations are often entertaining, but testing must be repeatable.

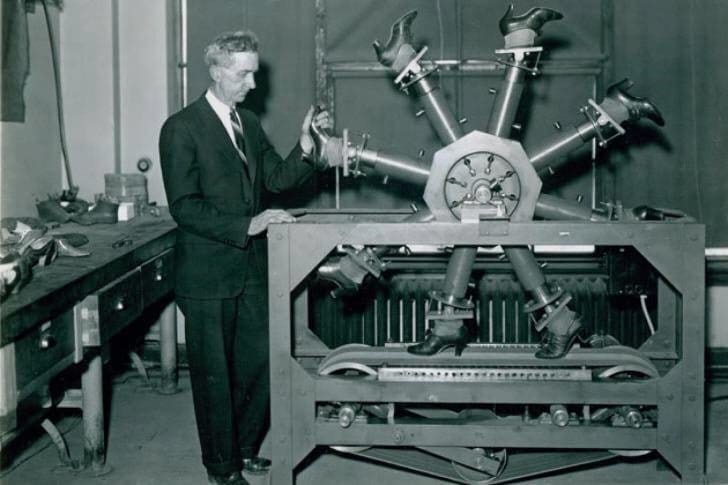

Machine developed at the National Bureau of Standards to test the endurance of women’s shoes, Washington DC, 1945.

Cue up Nancy Sinatra, “These boots were made for walkin’…”

yup. and taking something off the rack out for a weekend isnt ‘gear testing’ either.

i did tesing myself for polartec for a few years, then started running testing projects myself. its really not what people think it is.

Sooo how does one test gear then??? Seems to me using said gear and taking notes on it , is testing……

Testing requires a plan and repetition. Lots and lots of repetition. You can’t draw a real conclusion from a sample of one.

A well thought out protocol that is repeatable and a justifiable sample size that generates meaningful and quantifiable data; not a 4 minute video of Cleatus with a neckbeard saying “Wooooweee, let’s see what she’ll do.”

Using gear and writing notes is just cataloging a singular, anecdotal experience.

Often, what you see on Youtube, even if it’s a well thought out, is not necessarily testing, but a review.

its starts with defining what youre testing. testing what? you dont test ‘a jacket’ say, you test specific properties, of which there are thousands.

then you define what you are testing those properties for, and then what the test conditions are.

example; testing material Xs Y properties under Z conditions.

good tests have controls built in, ie a standard to test against, usually the competitors product or the previous generation.

lab testing is mostly for strict material datum and modelling further tests and expectations for results. you dont just roll out to see what happens on a test, you set up objectives and work on them. theres far too many moving parts to test everything at once.

the bulk of the testing iceberg is endless meetings and paperwork – where most of your alpha male types prove useless. yeah yeah run around the hills, then its twice as long evaluating ticking little boxes and details. id say 1 in 50 wannabe testers cant do this. dont like filling in forms? youll hate testing. its a job, its work, youre getting paid for the useful data part, the running round hills part is just the way you gather it. test versions are usually crappy looking – youre not testing how shit looks. stuff usually has known bugs in it, theres a lot of dumb ideas going around. you wont get cool labels, unless you think having SAMPLE ONLY. NOT FOR SALE stamped on it is cool (actually maybe it is…)

destruction and exhaustion testing is another type. sort of fun watching shit fail, painstaking analyzing the results. that FS ice climbing vid posted a week ago – do that soaked in mud. yeah a 417 works when misted with ice once. keep misting it at -20c till it doesnt then thaw it and repeat. anyone want to watch a 3hr youtube vid of that?

theres a form of reengineering too, where its not the product thats the focus, its the niche that needs addressing and you throw pieces at it to try and get a frankenstein solution thats then made properly (and the proper version then tested). risky but fun. i do a lot of that in very cold environments and have permanent cold injuries as a result. ive also had hyponatremia testing in the heat.

above all is your opinions dont matter – quality of your feedback does. on a good test you dont even know whats being tested. designers dont give a fuck what i think – im not a material designer. the ideal feedback is a bag full of damaged parts, 30 pages of questionnaires and a slide presentation where you answer questions at a stupid level of detail.

you will find most companies dont do much of it, basing their products off existing data with only minimal tweaks from anecdotal opinion. soldiers, guides and recreational users come under that, which doesnt devalue their input, but its not real testing either because the quality of feedback is notoriously low.

baseline is its usually hours of specific use that stuffs based on, and a pro tester gets that more effectively than anyone else. pay more for 500hrs of continuous use and you will get by a certain date to meet schedule. no soldier or climber can do that because they have their real job to do, but they can anecdotally add to the project in their own way.

We all test our purchases, but it isn’t scientific, feedback matters. In the end especially with clothing its what we prefer and feel comfortable in

Providing feedback to a manufacturer isn’t testing.

Your correct SSD but ultimately feedback from the users, assuming you get enough, is vital. Its hard to ‘scientifically’ test certain products like clothing

Actually it isn’t Gerard. Textile scientists, human factors engineers, designers, etc. do it all the time.

Here’s just one little primer for ya:

https://www.astm.org/Standards/textile-standards.html

😉

You need both, end user testing is important as it can point out issues with UIs, comfort, etc. But scientific testing for things like durability and performance are more important.

I will also say that end user testing isn’t sending out an one off thing to a random person. It requires a good sized qualified test group and focused survives to suss out the answers of the user.

^ BINGO!

The only way to test is by having lab and human testing , together. Both with the correct design of experiment, statistical rigor and correct end-user testers( in the right conditions). Anything else is anecdotal at best. Still valuable, but not in the same category as repeatable, well designed, testing protocols.

As a 20+ year experienced functional apparel guy, I can tell you that most manufacturers are not doing it right- mostly due to the cost of fielding 100+ people, in the right conditions.

I identify as a gear tester – therefore I iz wun.

I identify as someone who wants the benefits of:

1. free cool guy stuff

2. identifying as a cool guy

3. justifying bullshit antics and lab coats (thanks Derpadoo… I feel more complete)

Researching official-sounding certification to those ends. I’ll get back to y’all…

Disclaimer: I don’t wear high-heeled anything….

What’s really entertaining is seeing guys who tell others they test shit on here trying to justify their bullshit antics.

I believe Eric once said, “it’s not testing if you aren’t wearing a lab coat.”