When it comes to SOF clothing systems, Polartec has been there since the beginning, providing fleece and baselayer fabrics for the Lightweight Environmental Protection and later, Protective Combat Uniform programs. Although initially SOCOM selected commercial off the shelf fabrics for their environmental clothing, eventually they sought out specially engineered materials.

Enter Polartec Alpha.

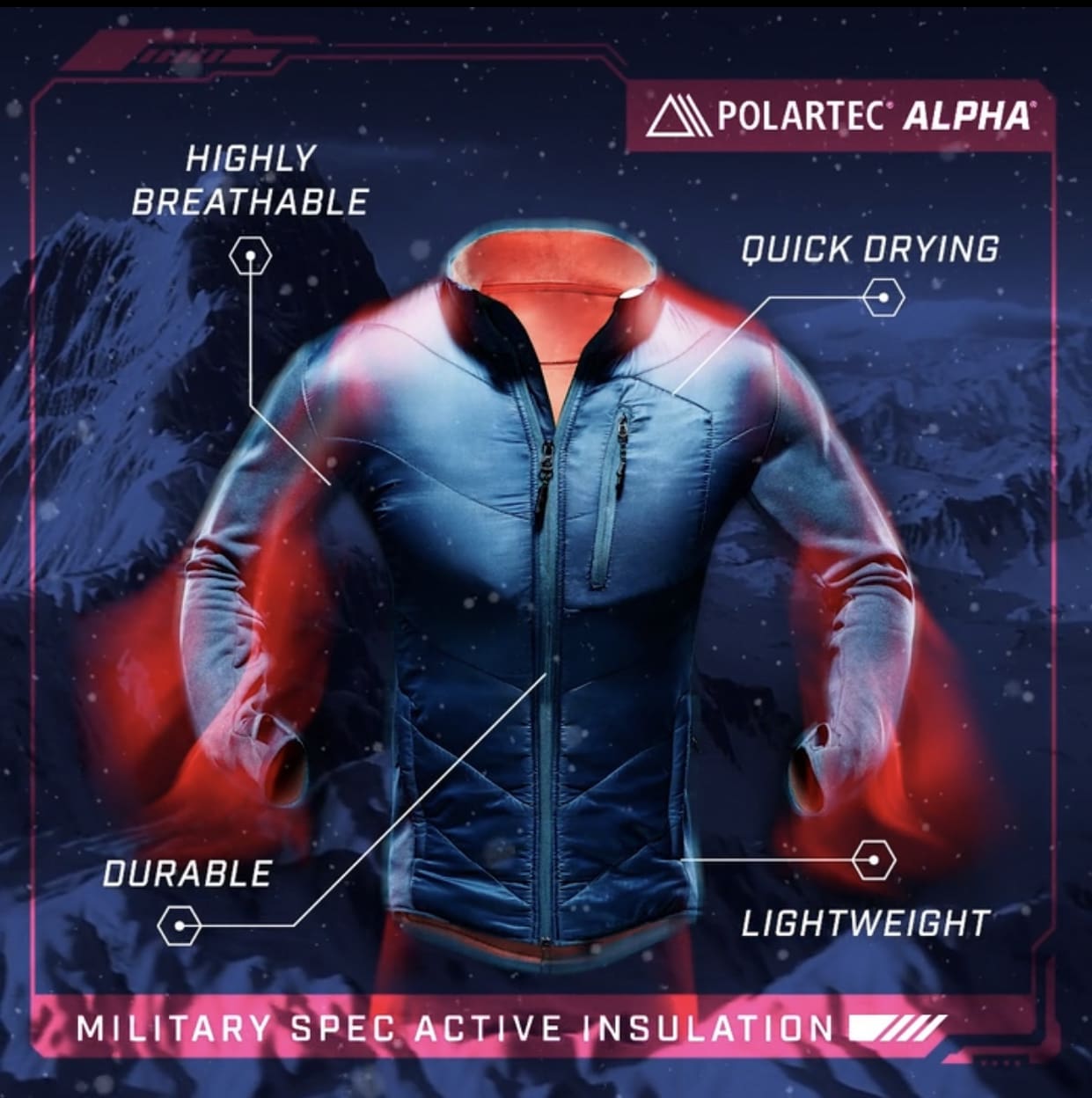

Polartec worked to develop an insulation technology that was not only warm, wind-resistant, durable, lightweight, quick-drying and packabe, but also breathable. The current product was not at all breathable, and breathability had become essential to SOF operating in cold mountainous regions with intense stop and go activity. By 2012 Polartec Alpha debuted, and through extensive lab and field testing in extreme environments––including cold weather combat training in Kodiak, Alaska, during which operators fully submerged themselves and then walked themselves dry––the SOF Protective Combat Uniform Level 3A Jacket became standard issue for every Special Forces Operator. It’s still in deployment today.

The hybrid product design of Polartec Alpha combines the performance attributes of base layers, insulation, and outerwear in a single garment.

But you don’t have to be a SOF Operator to use Polartec Alpha. Both it and Polartec Alpha Direct are now also used by consumer brands across the apparel market. In fact, SSD advertiser Beyond utilizes it in their A3 Alpha Sweater as well as other garments.

Light and compressible, the sweater relies on Alpha Insulation to transfer moisture away from the body to keep you dry and warm, while the DWR treated nylon ripstop shell protects you from wind and rain.

Read the entire Polartec Alpha story here.

Find the MTHD APHELION HYBRID FLEECE FULL-ZIP jacket featured in the Polartec Alpha ad @tacticaldistributors.com, brand page: MTHD

I worked with Polartec back when this was coming out (and still called strata) and it was a near revolution, based off new milling tech for making fabric. Took years tho for the fabrics they sandwiched it with tho to make speed. Only the last 3-4 years where its fully seeing potential. For a long time it was just treated like single filament insulation.