SSD will be transitioning to a new web server over the next 24 hours. You may experience a disruption in service. We suggest that you clear your cache if the issue persists.

SSD will be transitioning to a new web server over the next 24 hours. You may experience a disruption in service. We suggest that you clear your cache if the issue persists.

We just hit 28,000 active posts on the website. There of been more than those, but some have come down for various reasons over the years?.

Not doing too bad considering we have been publishing daily for just shy of 12 years.?

We have published so many articles

lately pertaining to the COVID-19 Pandemic that we’ve added a category to the site. This facilitates a single link to all of the coverage.

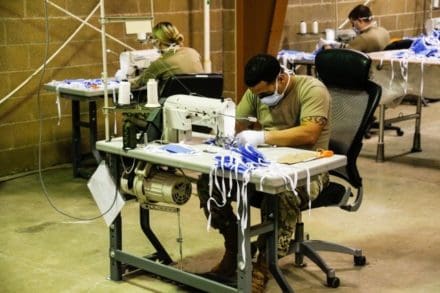

JOINT BASE LEWIS-MCCHORD, Wash. — 1st Special Forces Group (Airborne) medical professionals and logisticians stationed at Joint Base Lewis-McChord, Wash., manufactured personal protective equipment for routine care and protection against the COVID-19 pandemic March 31, 2020.

As the threat of COVID-19 continues to permeate the region, 1st SFG (A) Soldiers adapt to develop solutions to combat the virus and protect the force within both the Special Operations and JBLM communities. The most recent adaptation is the production of personal protective equipment.

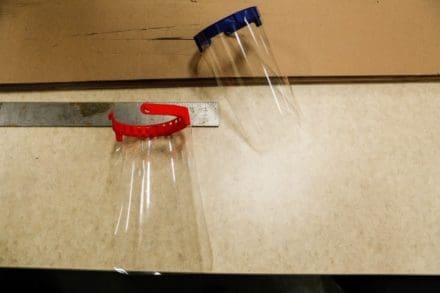

1st SFG (A), Group Support Battalion personnel used their resources and expertise to create prototypes for reusable respirator masks, face shields, and surgical masks for Madigan Army Medical Center and its regional partners.

The 1st SFG (A) riggers repurposed their sewing machines, that are typically used to repair parachutes, to assemble surgical masks.

“The Aerial Delivery Platoon will be able to produce 200 [masks] per day initially, with only five lightweight sewing machines,” said Lt. Col. Christopher S. Jones, 1st SFG (A), GSB commander.

Soldiers will continue to refine the process of producing the masks and improving them with feedback from medical employees.

“We’ll get better by week’s end and be able to produce 1,000 to 1,500 during a normal work week,” Jones added.

The masks will be beneficial immediately to personnel identified by medical professionals.

“The most likely application [of the masks] will be to have a symptomatic patient, one with a cough, sneezing, shortness of breath, wear the mask in order to reduce the amount of respiratory droplets contaminating the environment, helping reduce the likelihood that ill people expose others,” said Col. Rodd E. Marcum, 1st SFG (A) surgeon.

In this period of adjustment for many people, it is important to remember what the priorities are – protecting the force and their families by following medical guidelines.

“Nothing is more important as we work through this unexpected challenge than following the recommendations of public health professionals. Physical or social distancing is critical in reducing the chain of transmission,” said Marcum.

As we continue this fight, Jones expressed pride and confidence in his Soldiers and said he looks forward to witnessing the impact their hard work has on the nation as other forces join the battle against this disease.

“I believe this is a phenomenal effort to help our healthcare professionals and fellow Americans,” said Jones. “We’re collaborating with [Army Special Operations Forces] and conventional forces across the Army to make a difference. The effort in and of itself is a worthwhile exercise in how to innovate to provide solutions, especially as the U.S. military has the best capability in the world.”

Editor’s Note: At the time of publication 1st SFG (A) provided 300 surgical masks to Madigan Army Medical Center.

Story by 1st Special Forces Group Public Affairs Office

Photos by SSG Ryan Hohman, SGT Joe Parrish and SGT Adam Armstrong

It’s Tactical Helmet Health Week at Agilite. As the world leader in tactical helmet covers they’ve decided to to spread helmet damage awareness. Watch the tragic story of Billy and Jennifer:

Not many people know this, but even the most high-end ballistic helmets have vulnerable painted surfaces. When they’re scratched or chipped, it can slowly cause irreparable damage to the ballistic layers underneath and void your helmet.

Don’t risk it! One serious knock and your helmet starts a process that may require you to stop using it several years early, so be responsible.

To celebrate Helmet Health Week, Agilite are doing 2 things this week:

1. A Sale on all helmet covers!

2. They’ve made it super easy to know what cover will definitely fit your helmet type (they cover all common helmets) as well as offering their one-size-fits-all Helmet Bridge option.

agilitegear.com/collections/helmet-covers

Yesterday, I spoke with Scott Jones, the founder of Beyond Clothing who now owns Further Designs. He shared an incredible story with me.

The news of the day remains the COVID-19 pandemic. As scary as it might be, it is awesome to see Americans pivoting their efforts to counter this threat to our health.

The project is home sewer manufacture of filtered masks for use by those who have given up their N95 masks for use by higher risk groups. They’ve created a Facebook Group. Although it was founded by folks in Bellingham, Washington, they encourage others to join and collaborate.

Here is Scott’s story:

I was contacted on Friday afternoon by a friend who is a nurse at a local hospital. She was on the verge of tears fearing that soon she, and her peers, would not have access to any face protection while providing medical care to patients. We are only 90 miles, from Seattle, WA.

I was not behind the idea of simply creating cotton masks, but once the idea of a replaceable micron filter came up, I was on board.

Might as well make em look good, right?

Over the last 48 hours, I have worked with a team of local doctors and nurses, engineers, and others to create the Frontline Mask. As I did at Beyond, I like to be able to create as much versatility in my designs and production as possible. Especially in a dynamic world where items disappear from stores and online overnight. I couldn’t rely on elastic, or a certain fabric, or a certain filter. It had to be able to be ‘plug and play’ by the user, and the mask had to be able to handle the changes.

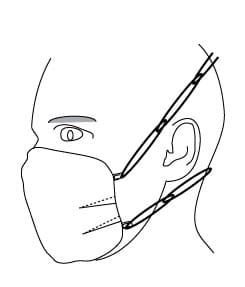

The mask in its current state, is made of 2 layers of tight weave cotton, with a slit on the face side, for the placement of a filter, that fills the entire mask. Filters such as vacuum bags, industrial filter fabric, hepa filters or the like will be able to be chosen, cut in the field and inserted. The cotton mask will be able to handle the changes to the filter requirements. Although Covid-19 is incredibly small, the transmission occurs on large water droplets that are far easier to stop. Although hospitals and doctors offices are not yet allowing this type of mask, we sadly feel that they will need to soon. Even the CDC has mentioned this regarding bandanas.

We also feel that the FrontLine mask will help those who have generously given up their own masks to more at risk medical professionals; dentists, PT, clinic nurses, soldiers, and senior care centers.

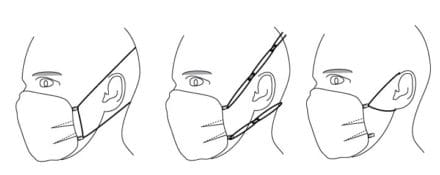

Attachment was also a challenge. To make the mask easily made world wide, but as safe as possible, the attachment to the face had to be dynamic and come with multiple solutions.

Different means of attachment.

The one I find to be most comfortable are daisy chained rubber bands applied to built in anchors in the mask. The nose piece is malleable farm wire, or clothes hanger wire.

The solution is comfortable, air tight around the face, able to go over a N95 mask, and able to handle any filters available.

The Version 1 spec package, patterns and instructional videos are available at fb.com/frontlinemasks or furtherdesigns.com/frontlinemasks and will be continuously enhanced as feedback comes in. We’ve received updates and recommendations for filters from around the US, and recommendations will be listed after further vetting.

If anyone in the Soldier Systems sphere has expertise or recommended items please have them contact me at scott@furtherdesigns.com.

As a business you will most likely feel a pause, but hopefully, this will be a short crisis and our economy can get swiftly back on its feet. As always, SSD stands ready to do what we can to help.

One of my goals when I created Soldier Systems Daily in 2008 was to serve as a resource for industry, both here in the United States as well as abroad.

To this end, we are waving the fees associated with sales announcements and offering them cost-free for the foreseeable future to help your business reach customers.

Just go here and fill out the form to upload your sales ad. We will review and post them to the site as quickly as possible after receiving them.

Additionally, trade shows, where you would normally launch new products, have been delayed or cancelled outright.

SSD is here to support your business, product, and service launches. There has never been a cost associated with this. Feel free to email us press releases in text format with photos less than 2mb each in size (no adobe acrobat versions). If you’re curious, our column width is 440 pixels.

SSD Readers – Keep your eyes on the Sales page for regular updates. We also ask that you support those businesses that support us as advertisers. Many have stood by us since the beginning and they will be focused on their survival during this time.

Let’s all get through this together.

-Eric Graves

Editor

According to the Air Force Enlisted Heritage Research Institute, who shared this photo from May 1967, this is USAF SSgt Barbara J. Snavely who became the first enlisted female NCO to be assigned to US Military Assistance Command, Saigon, Vietnam.

What gets me is the weapon grip in use at the time.