Fenton, MO – FirstSpear, manufacturer of military and law enforcement load bearing equipment, armor platform technology, and performance technical apparel has released its revolutionary Tubes™ Rapid Release Technology for individual and commercial sale. The Tubes were originally released on flagship FS plate carriers like the Strandhögg and Assaulter Armor Carrier. Early adopters within the Special Operations community and Law Enforcement proved early on that FirstSpear’s Tube system significantly enhances the capabilities of the operator while reducing the overall weight of their personal protective equipment.

“We put a tremendous amount of R&D into developing the next generation of personal protective equipment, and the Tubes system is one of the most significant results of that effort. Now that the system has proven itself with the most demanding users, we are proud to make the technology more readily available.” CEO, Scott Carver –FirstSpear.

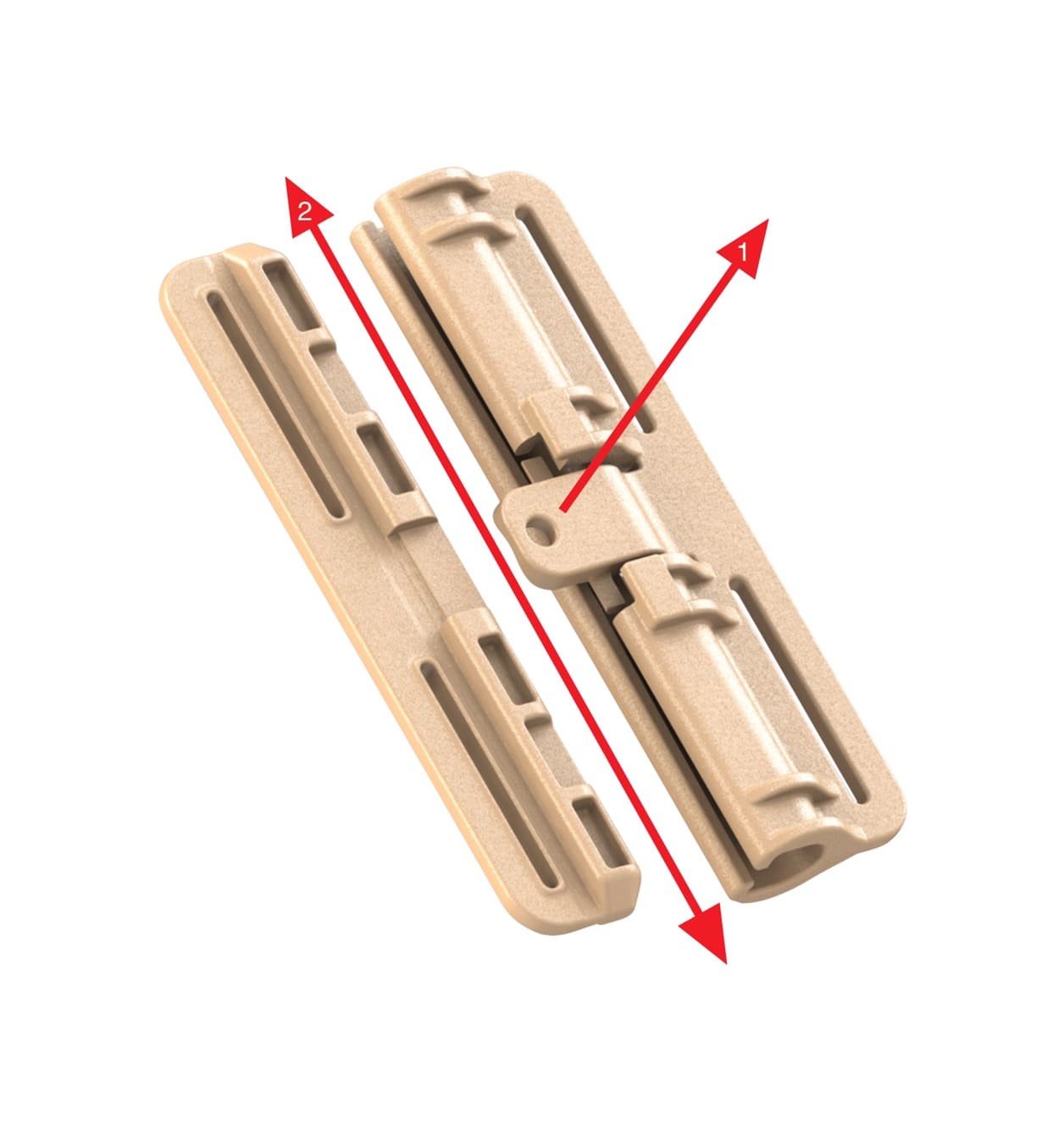

Tubes are available in 2” and 4” configurations and feature one of the fastest most secure single-handed PPE closure systems available on the market. Older style body armor carriers have closures that utilize either a heavy hook and loop flap system that quickly wears out and collects dirt and grime or a release buckle that is clumsy and unable to provide a stable platform while under load. Most releasable armor carriers use a complex cable system which is virtually impossible to put back together quickly, creates a single failure point, and if not routed properly can be disastrous.

The Tubes provide a recognized and proven solution for military / Law Enforcement equipment manufacturers that cuts significant weight and bulk from the front of the carrier and meets many of the latest industry requirements. Tubes are BERRY compliant, constructed from IR signature suppressive materials, have exceeded mil-spec testing standards, and are currently being fielded to the most demanding users for land, maritime, combat diving, and airborne operations.

The single hand operation is not only easy to learn, but the muscle memory of putting the vest on and taking it off each day is the exact same movement performed during an emergency to release the carrier. The Tubes also ensure the cummerbund sets in the same place every time, avoiding misalignment and the risk of improper armor placement of the cummerbund. In addition, the system speeds up casualty assessment, transport, and decontamination protocol in a chem/bio environment.

“Patrol officers now have the ability to quickly throw on level IV plates during a crisis, and if you’ve got a casualty in the field, a medic can easily get your armor off, patch you up and get your armor back on in seconds. Anyone who has ever worn a plate carrier can appreciate the ease and security of the Tubes.” VP Business Development, Ronnie Fowlkes – FirstSpear.

The Tubes are now available to approved equipment manufactures and Tube Kits will be ready for individual sale coming soon. Available in Black, Tan 499, Coyote 498, and Foliage in 2” and 4” sizes. Contact FirstSpear to incorporate the industry leading Tubes Technology in your next project.

Tags: FirstSpear

Is there a particular department or individual we should contact in regards to this? I’ve sent several emails to First Spear in the past about incorporating Tubes into designs, but they have all gone unanswered.

you would have to pry my first spear vest out of my cold dead hands before I would mess with my old eagle carrier again. I have seen Safariland and Tyr are already using the tubes this is a great evolution for the industry, good work FS

Problem with the tubes is that 3″ gap between platebag and cummerbund. That is critical real estate for easy to reach / quick grab items. Innovative buckle but the gap is something to be desired.

Its less gap then any other buckle on the market, not sure what you are expecting. You can always use velcro, but this is the best option if you don’t like the fuzzy stuff.

Lots of FS designs incorporate a pocket right under the tube gap to use this real estate as well.

I bridged this gap with a MOLLE pouch; weaved it with some gutted 550-cord and secured it with a barrel-lock and knot. This has negated use of my forward-left release, but I just get into my carrier from the right side and I now have use of valuable real-estate at my 10 o’clock.

They build them into their designs… it is pretty hard to get them for other competitive companies… they are also no as easy to reassemble when under tension IMO

REALLY would like to see these finally expanding out to other quality companies after all these years. The AAC and similar designs are pretty much bang on the money as they are but you never know what other manufacturers might come up with.

If Vel Sys and FS could get together and build something with the placard compatibility up front (as I’ve mentioned to them many a time) I’d be a happy camper for sure.