In order to tell you about clothing brand Rock Face, I’ve got to first tell you about their parent company, Coville.

Founded in the heart of the Carolinas, Coville is an amalgamation of three companies. Up until the 1980s, the region was known as textile country and even today, it’s home to much of what little we have left of the industry. Coville remains an instrumental component in the Berry compliant supply chain.

Founded in 1976 by Henry Jordan, much of Coville’s company’s assets, now owned by a private, family interest, come from its later purchase of Alandale Knitting, which itself was founded by Alan Gutschmit in 1966. Gutschmit was a veritable genius in the knitting game, amassing 13 patents for machinery which remain the standard, even today. Founded in 1975, Carolina Apparel Group rounds out Coville’s capability as their cut and sew facility. Together, they work on each other’s strengths.

All together, these three companies bring over 125 years of experience in the textile industry. What’s more, they are all located with 30 miles of one another, offering a vertically integrated company with expertise in material and product development, fabric knitting, and garment construction.

But Coville is not an island. It works closely with as many as 20 other vendors and suppliers in the area to provide Made in USA materials, value added services, and finished goods.

Don Trexler, CEO of Coville, related that their suppliers are critical to their success. In particular, he mentioned yarn producers Pharr Yarns, Shuford Mills, Parkdake Mills, Beal Manufacturing and Frontier Yarns as well as fabric finishers Gentry Mills and Southfork Industries, as key affiliates. With these suppliers so close by, issues can be fixed very quickly and wait times and transportation costs are cut.

Rock Face was founded in 2003 as a long underwear brand for sale in such outlets as JC Penney and Tractor Supply Co. At around the same time, Coville started manufacturing performance FR garments for the US military in response to the threat of IEDs to our deployed troops. Not long ago, they decided to expand Rock Face’s offerings by leveraging the lifesaving technologies they’d developed over the past 15 years. Additionally, these new products result in brand focus on the tactical market’s military and law enforcement end user.

While Coville provides various services to other companies in the textile industry, including the production of finished goods, the concentration of Rock Face on the tactical customer was an instrumental part of Trexler’s strategy to maintain a more consistent demand on Coville’s various capabilities, keeping machines running and employees on the job. Scott Wilson expanded on this, “We are a manufacturer that has a brand.”

Rock Face offers both FR and Performance garments, bringing design and materials to the equation. They have control over the comfort and properties of their garments. For instance, they integrate moisture wicking and odor control into the fabric and can tweak the level of air permeability and how quickly it will dry. All of that adds up to sustained comfort. Trexler said, “It’s a superior product from a hand and construction standpoint. On top of that, Rock Face offers a lower price point.”

Don Trexler related that he also wanted to recognize key players at Coville who have made Rock Face happen, Scott Willis, Nicole Vineyard, Morgan Richardson, and Tyler Henson.

Now that I’ve explained what makes Rock Face tick, on to the product. They offer two distinct lines which share garment design and an emphasis on performance characteristics. The difference is that the Flame Resistant line adds FR properties to the mix.

• 4.5-ounce climaGuardTM fabric blend

• Innovative Spinning Technology

• New fiber blend creates an athletic fit with high stretch & recovery

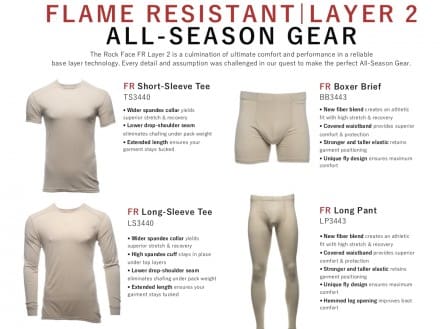

Layer 2 – All Season

• 5.5-ounce climaGuard fabric blend

• Innovative Spinning Technology

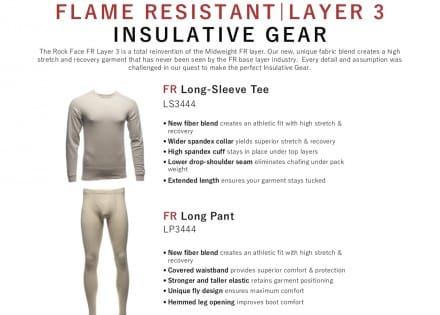

Layer 3 – Insulative

• 8.5-ounce climaGuardTM fabric

• Innovative Spinning Technology

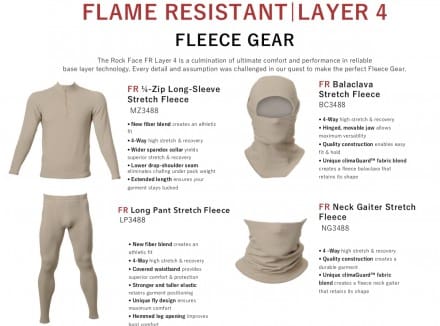

Layer 4 – Fleece

• 10-ounce climaGuardTM fabric blend

• Innovative Spinning Technology

• 5-ounce climaGuard fabric blend

• New fiber blend creates an athletic fit with stretch & recovery

Cold Weather

• 6.5 ounce fabric blend

• French Terry construction offers ultimate insulation values

• Pick Resistant due to nylon facing

• 4-Way High Stretch & Recovery

All of the garments are constructed with true flat seams to ensure comfort. These high-density seams also last longer. Additionally, everything is available in sizes XS-3X meaning it will support a full uniform program. Across the board, everything from the fiber to the packaging is Made in the USA!

Both lines share a color palette consisting of Sand, Tan 499, Coyote, Black, Navy, Foliage Green and Marine Olive Drab. Additionally, they will provide custom colors upon request. Naturally, minimums apply. Don’t take this color card as gospel. I’ve seen the garments in person and Coville works diligently with dye houses to match industry standards.

Since soft launching the line at SHOT Show, several military and LE Agencies have adopted Rock Face products. Even now, Rock Face is expanding their availability to military customers, with placement in LCI stores on 40 military bases.

Feel free to contact Nvineyard@rockfaceusa.com or learn more at rockfaceusa.com

looks like maybe tan and coyote color swatches are swapped.

Reading IS fundamental. Although I disagree with your assessment, I did state not to get worked up over the color chart.

reading – you mean this part? “Don’t take this color card as gospel. I’ve seen the garments in person and Coville works diligently with dye houses to match industry standards.” Lighting, paper inks, approximation all can have an impact on 499 vice 498. The yarn product is what matters for the final product.

No word on the fiber composition used.

Contact them.