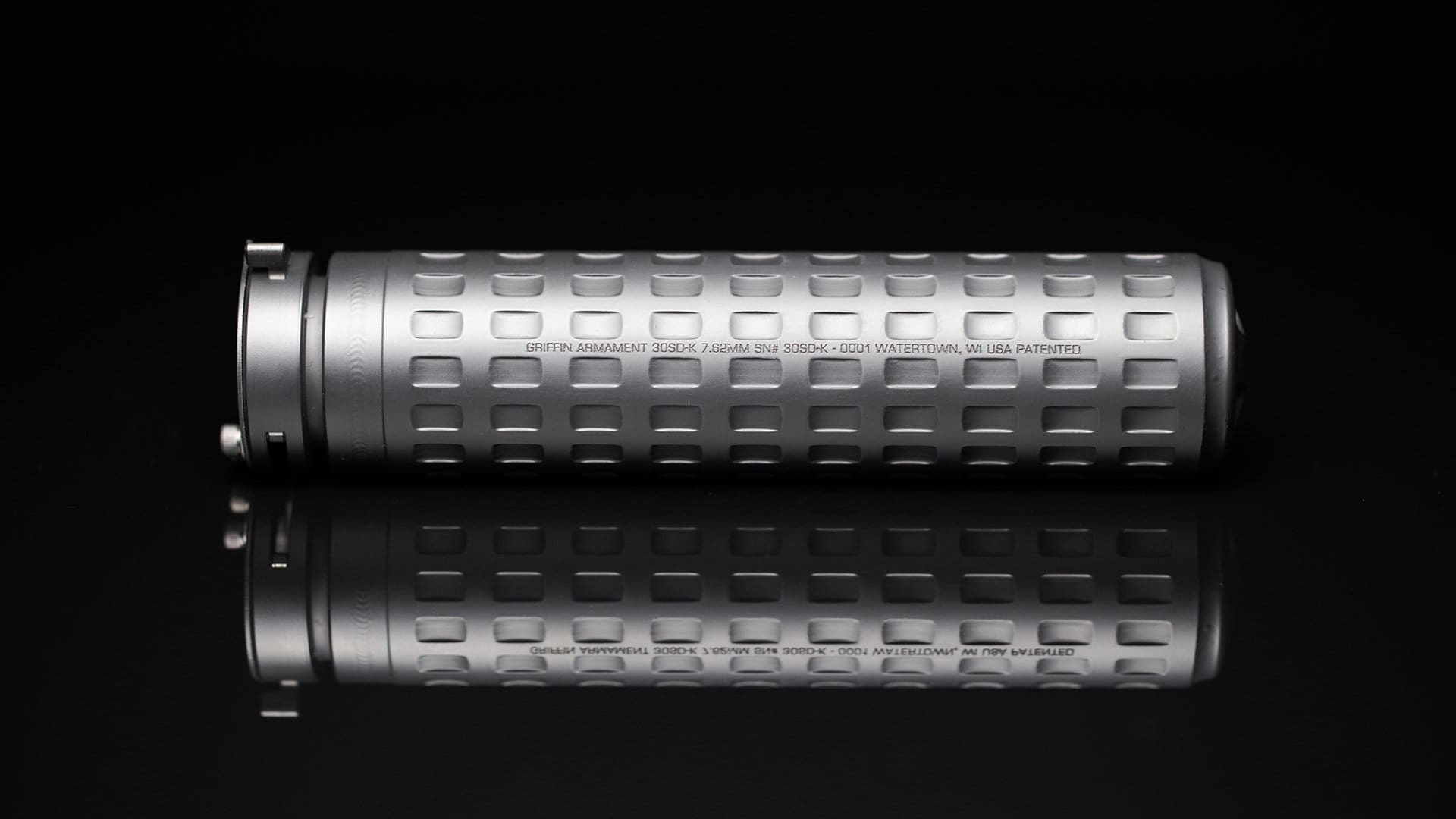

Griffin Armament is proud to introduce the 30SD-K to the GATE-LOK™ product line, a .30 caliber silencer with size and weight specs similar to traditional full size 5.56 NATO suppressors. This new product development stemmed from Griffin’s devotion to its customers and end users who have been requesting a shorter, .30 caliber GATE-LOK™ variant for some time. The 30SD-K was engineered specifically for semi and full auto applications and features Griffin Armament’s patented HEDP baffle technology which optimizes flow and achieves properly balanced blowback and muzzle performance. Signature reduction is not exclusive to sound performance as the 30SD-K also features Griffin’s patented low profile, integrated 3-prong flash hider end cap which further reduces flash signature versus tradition designs.

Austin Green, Griffin Armament’s Founder and Lead Engineer offered this comment when discussing the 30SD-K and the GATE-LOK™ product line:

“I originally developed the GATE-LOK™ interface after encountering shortcomings in other designs that interfaced with NATO style muzzle devices. The goal was for a simple, robust, active retention mount that didn’t incorporate any wear prone geometry, had minimal POI shift, and could be mounted easily with one hand. I believe we have absolutely achieved that with the GATE-LOK™interface. And now with the 30SD-K, Griffin Armament end users have the versatility of a high performance .30 caliber silencer with the size and weight similar to that of a traditional 5.56 can. “

30SD-K Features:

• 17-4 PH Stainless Steel construction

• Hi-Temp Cerakote finish

• 5/8×24 GATE-LOK™ Muzzle Brake included

• Patented HEDP™ baffle stack

• Low profile 3-Prong Flash Hider End Cap

• Compatible with all M4SD and 30SD mounts

• $945 MSRP

30SD-K Specs:

• 6.6” Length

• 17.8oz

• 127dB SPL with .300BLK (Subsonic)

• 136dB SPL with 5.56 NATO

• 138dB SPL with .308WIN

For more information regarding the 30SD-K, other GATE-LOK™ series products, or any of Griffin’s badass kit offerings, visit their website at www.GriffinArmament.com.

Looks like they just bored out an M4SDII. Same size and weight.

Oh look, just like KAC did almost a decade ago. Griffin’s pattern of ‘innovation’ continues!

We had a military unit visit looking for a Paladin suppressor that would accomplish some crazy performance specs on a specific caliber and unique platform. We had 11 days notice and had made 18 prototypes and had a design that would do what they requested when they showed up. That developed baffle system is in the 30SDK. It is not just a bored out M4SD II.

“I originally designed” doesn’t mean “I copied a muzzle device from one company, and I copied a different company’s can; I then mushed them together.”

Dang I misquoted, I meant to say “developed.” I haven’t had my Wheaties yet. I guess Griffin doesn’t eat Wheaties either, so they just copy everyone else.

Only Wheaties from Vero Beach/Titusville. They’re like the Condor of firearms parts.

Isn’t that a SureFire brake? Like exact design?

It’S “iNsPiReD”

But yes. Like most of their products, they are incredibly derivative.

If you took a look at the muzzle device and referenced the surefire patent you would know that what makes the Surefire brake unique is an ak74u esque chamber that comprises the first baffled chamber. The chamber has asymetric ports designed to push the right hand shooters muzzle down and left to compensate for the muzzles relationship to the impact of traditionally high bore axis over the buttplate, and recoil force on the right shoulder of the shooters body which imparts a rotational moment to the shooter. We dont have an ak74u style chamber in the muzzle device and we did not go for assymetric right/left porting because sometimes shooters change shoulders. There is no intellectual property overlap.

Griffin – we put the ‘rattle’ in your battle!

I will pass on ANY and ALL Griffin cans after this last fiasco with customers. Maybe Griffin should be releasing the serial range for affected Recce cans rather than focusing on building another KAC copied suppressor.

The cans which had that issue continued to be functional ( safely suppressing gunfire) and were serviced or are able to be serviced. An assembly welding employee who no longer works for the company was singularly responsible for the existence of that qc problem. Unfortunately companies are organizations comprised of people and sometimes people become undependable or have a lapse in memory or judgement that effects the company.