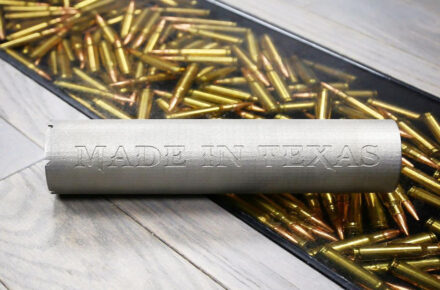

The SINTER is a monolithic 3D-printed 6Al-4V Titanium silencer from Radical Firearms.

The manufacturer advises,

“This Radical Firearms suppressor is 8 inches long, 16 ounces, and rated up to 300 WM. If you thought it couldn’t get any better, it does! The Sinter’s full titanium construction means you get durability without any added weight.

It’s not just about the insides for the Sinter titanium suppressor, but it also has to do with its unique aesthetic appearance.

The honeycomb exterior is intended to help dissipate the heat due to its increased surface area, helping the Sinter cool down faster. This is a wonderful feature since the Sinter can withstand higher rates of fire!

With its muzzle brake taper mount design, you’ll also be able to mount your silencer onto your host firearm and be ready to rumble in no time at all.”

Sinter Silencer Specs

The SINTER is one of the lightest, most durable suppressors on the market to date. Tested on everything from .22 WMR to 300 WM, all calibers are hearing safe. The internal design creates a robust superstructure unachievable through traditional manufacturing methods. Constructed wholly of Titanium 6Al-4V, the SINTER has a high strength-to-weight ratio creating a durable and the lightest weight commercially available suppressor for everyday use. – Radical Firearms

“From the slim-lined profile of our RPR rail to the multi-functional MHR hybrid rail, we’ve got you covered. Whether it’s unsuppressed down to integrally suppressed, Radical Firearms has multiple options available. Pictured from top to bottom: • 16″ 5.56 RPR rifle • 15″ 5.56 MHR rifle • 5.56 integrally suppressed rifle • Sinter Titanium 3D printed suppressor.” RF

Sinter Spec Sheet: Sinter Spec Sheet

16 ounces? Pass

Well, here in Denmark, I can buy a suppressor for 200$, that includes getting the barrel threaded.

But, dunno why, but stuff like this itches something inside, guess it’s my inner gear whore – do want.

Although it’s heavy as fuck, and by that defeats the purpose of 3D printing.

I’m glad you can buy suppressors so cheaply and easily; it must really soothe the burn of having to pay so much for the licensing to be allowed the rifle it goes on.

While the suppressor may be heavy, it is a technological leap forward. It’s also bringing this type of manufacturing closer to the average person. While sintering technology is still quite expensive it is not as expensive as getting, tooling, maintaining, and running a CNC vertical mill. I’m hopeful as sintering technology continues to grow, improve, and cheapens that we’ll be printing cans (that we will of course Form 1 with the BATFE) in no time.