MATBOCK was in search of a lightweight material that was not only strong, but durable and would outperform existing materials. After 2.5 years of searching and failing to yield acceptable results, MATBOCK decided to develop their own blend.

In keeping with their motto of “Lighter Faster Warriors”, they had to ensure that the material was going to be lighter than anything else on the market so they started looking at fiber based materials. This led them to test materials such as Tyvek®; however, it was not strong enough. In keeping with that same mentality they started researching sail cloth or dyneema based materials and ultimately Ghost was born in an alloy type laminate allowing for the strengths of many different materials to shine through. After years of testing on and off the battlefield, Ghost has met the demanding requirements.

Traditional manufacturing methods of nylon do not work well with Ghost, leading MATBOCK to continually test, develop and improve their methods for construction. At nearly half the weight of alternative fabrics, and nearly 4 times stronger, they are excited to finally bring this capability to the tactical gear market. MATBOCK would never put a piece of gear in the field that did not meet their own rigorous standards as it is their own brothers, friends, and teammates depending on it.

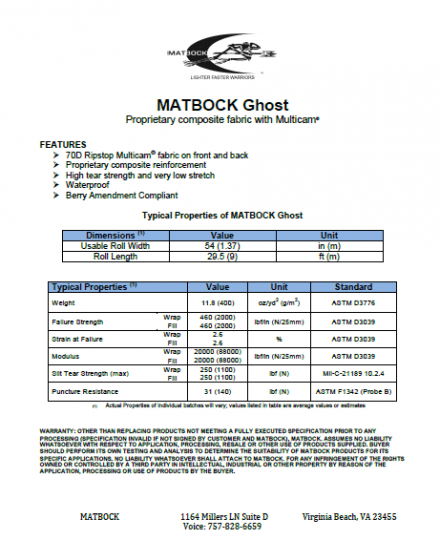

Below you can find the Spec Sheet for Ghost.

Tags: MATBOCK

I’ve also tested Tyvek as a solution. Thought I was onto something but nope lol.

Great to see further strives in material.

Two quick things, I was wondering if they were going to sell the fabric? and I think the zip code might be wrong on the first page of the PDF?

1) Yes, but on a case by case basis. Please email us – admin@matbock.com

2) Thanks and we will fix that. 23451 is the correct zip code.

Thanks for the info, I’m always running into people/customers looks for stuff made new materials.

Cuben tech started bonding 10D nylons and playing with epsilon (30D) an cuben fiber a few years back. had a few minor issues but seems they have nailed it. MMI got in on the market early, selling pencotte paterns in this ‘ghost technology. Just ahead of its time back then, i guess. Their 500D version makes an AWESOME waterproof pack that weighs nothing. Now owned by Dyneema, i believe they now do all the laminates in house (or at least own the old cuben tech facility), and this new double sided version is nice! They have also bonded Event membrane with dyneema and a nylon outer shell, makes a pretty tough ultra light set of rain gear. and now with the black dyneema on the market, you can find a full dyneema outer shell on the cuben tech laminates. Pretty interesting stuff.

Wow! Finally I got my answer. So I’m not like “a pig looking at a wristwatch” as someone described my comment on your magazine pouch. Matbock’s .pdf says exactly what I said (70D nylon ripstop) + mysterious reinforcement.

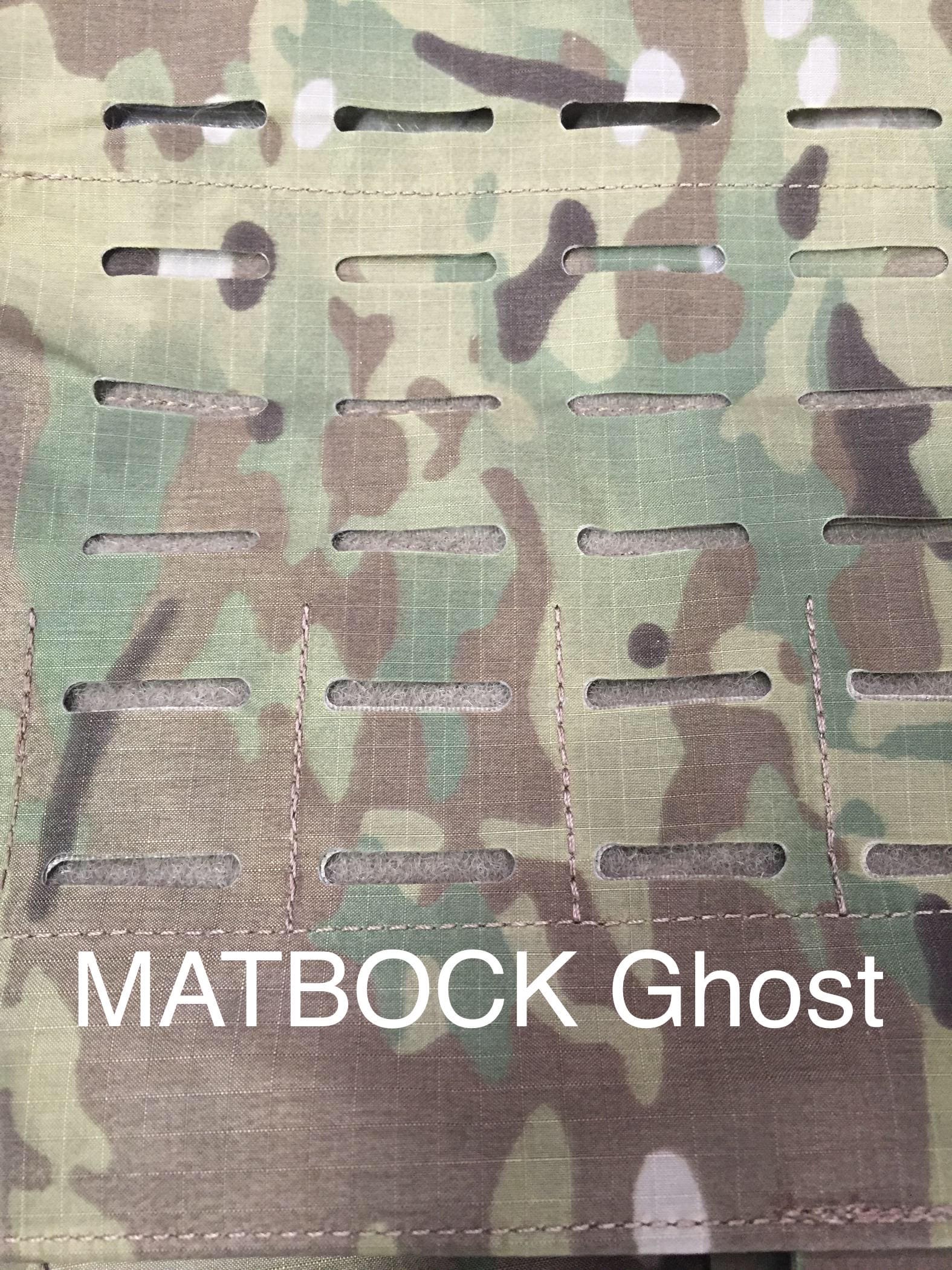

@Matbock, how do you think to solve the problem about fluffs of the holes?

In this image the holes seem to be better defined than the images on your website.

No, you’re still looking at that wristwatch but you’re concentrating on the band rather than the watch. The secret sauce here is the composite. The 70D is just a face fabric, like a paint job because the material that does all of the heavy lifting doesn’t print well and tends to have a bit of a sheen.