The Punch and Pull entry tool may be the next evolutionary step in manual breaching kit. It may, in fact, relegate the hallagan (which a lot of folks incorrectly call a “hooligan”) to a much more secondary role.

The Punch and Pull entry tool may be the next evolutionary step in manual breaching kit. It may, in fact, relegate the hallagan (which a lot of folks incorrectly call a “hooligan”) to a much more secondary role.

“A lot of tactical guys are a little iffy at first,†says the Punch & Pull’s designer, “but once they try it and see how well it works they love it. A SWAT team should have more options on an entry than a hallagan, a ram and a damn big hammer.

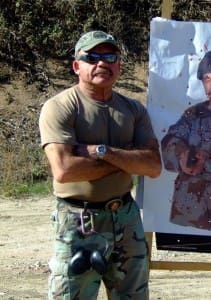

Originally developed in 1996, the Punch & Pull was built by Rick Lopez, a 20+ year veteran of LAPD’s D Platoon (SWAT) and Narcotics Division for use on the fortified doors their narcotics officers were encountering on drug warrants and SWAT operations. Because it causes a lot less collateral damage (and doesn’t leave quite the same amount of wreckage) than other breaching equipment he describes it as more “brass friendlyâ€.

“Its actually pretty simple,†Lopez advises. “It’s usually a two man operation. The guy with the hammer spike sets the hole in the security door, the guy with the Punch & Pull, handling it like a weapon at port arms, comes in at 45 degrees and sets it. “BAM,” it comes open, opening up the inner door for the slam man [ram carrier].†The Punch & Pull remains hooked so it’s not in the way, lying underfoot or encumbering anyone during the immediate entry.

The spike is set by the doorknob to preset the Punch & Pull’s hold. It doesn’t break the deadbolt (most times you can barely bend a deadbolt), it tears the plate open. The plate is much more vulnerable than the rest of the mechanism. That’s what the Punch & Pull busts out. (Lopez prefers to do a door peal on the doorknob side at an angle to pop the door. It puts all the tension around the doorknob.

“You don’t want to hit the center of a door with it,†Lopez warns. “Some guys did that despite being trained not…that puts the torque on the hinges. They wound up with the door right on top of them when it came off.â€

Note: if the target door is more than moderately fortified (like if it’s strongly lagged), the Punch & Pull probably won’t work. “It’s popped some lagged doors before,†Lopez says, “however they were lightly lagged. That’s why proper surveillance and intel gathering is essential prior to ever making the approach. If it’s lagged heavily in the door frame or the floor using welded bolts, you’re going to need to do a vehicle pull.â€

The Punch & Pull is in use by a number of different agencies and units, including the LAPD, Ventura County SO, DEA, FBI and several municipal departments. Rick, who is a former grunt turned ANGLICO Marine, has also provided several to units at Camp Pendleton and taught them how to best employ it.

For more information, check out www.PunchandPull.com. You can also e-mail Rick at punchandpull@hotmail.com or call him at (562) 754-3214. He is on Pacific time.

Some video featuring door peels vs. door pulls, along with some training iterations with the Punch & Pull visit Youtube.

– DR

Tags: Punch & Pull

There is a reason it has been around for 20 years and hasn’t really taken off….it works well in limited situations but is heavy, cumbersom, and takes two/three people to deploy. It is a tool and every tool has its place but a do everything item that it is sold as…no way…just my .02

The Halligan tool which is often incorrectly spelled hallagan…

A T-post driver with captive hook.

I sold commercial hollowmetal steel doors and frames for eight years, and it’s not hard to spec a door to defeat that. A detention grade 12 gauge door and frame propery anchored would do it. Add lightweight fiber reinforced concrete to the first lock core, done. Hi impact resistant.

As part of a tool set for a metro, this could be helpful, but the assumption is that residential grade construction is the target. Up against the now common FEMA hurricane/tornado rated commercial door, not so much. And they’ve been out long before Katrina. I was selling them for personal safety and security vaults to high end homebuilders in the ’90s, and the Midwest is notoriously slow picking up on this.

The wall itself can be even more vulnerable with appropriate deconstructive tools – the real choice is which opening is the quickest and easiest to create. Why spend a half an hour beating your way through a door when you can use a cordless reciprocating saw and create one, or simply unfasten the exterior materials and punch thru the sheetrock, as our more clever B&E engineers figured out long ago?

Keep a good working relationship with former citizens now working commercial construction since their release, and they can point out the weaknesses in construction they would consider.

I can see the use cycle reduced a fair bit if the tip of the P&P were modified to do the “punching” instead of having a separate operation. Maybe if the hook part was “spring loaded” you could punch through the door and hook to it in one motion…

MarkM-That is some great insight, thanks for your post.