Next time you want to run out back with a gun and “test” it, take a gander at this.

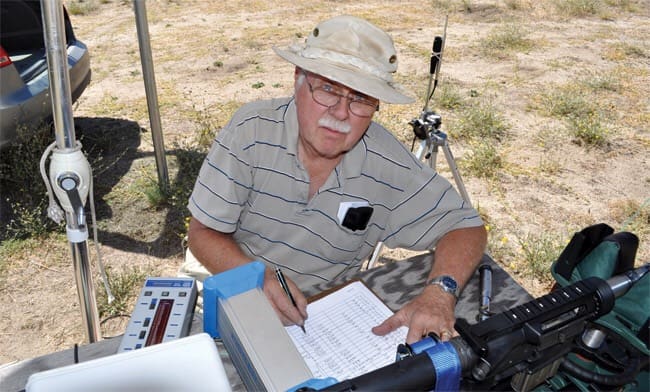

Even though Doc Dater isn’t wearing a lab coat he is do instructing the heart of testing, which is painstaking data collection. Photo from Small Arms Journal.

Small Arms Journal has published a great story entitled “Barrel Length Studies in 5.56 Weapons” where they investigate the effects of bore pressure upon projectile barrel exit of varying barrel lengths. They go into detail on how they prepared the test and how they collected the data as well as the results. A fine piece of work.

That was an excellent article. Its been published in a few places including Surefire Combat Tactics. Probably the most legitimately worthwhile article published in a gun rash in a long time.

I agree completely. I read this a couple of years ago in Combat Tactics. Was a good read and actually informative.

For me- this is a case of Science catching up with “gut feeling”. For all of the advantage gained in Close Quarters by lopping off the barrel, the loss of reliability and lethality- renders the exchange a poor one.

This coupled with the intense discomfort of being beside a fellow assaulter blasting away with a Mk. 18 inside a structure….or God forbid at night without a suppressor fixed…..

I would trade my little blaster for an M4 and its 4 additional inches.

What loss of reliability are you referring to by using a SBR? This study is pretty much demonstrates That you should not be using 855 in any thing shorter than a 20 inch barrel. Use 262, 318, or even 255 if you aren’t worried about anything past 100 yards. And why are you worried about discomfort if you are being issued a MK18, you probably getting Peltors at the least, and rifle shots are going to be the least of the problems once breaching occurs.

We have found the failure rate from the locking lugs back through the hammer spring to be accelerated in the Mk 18 (when putting a lot of rounds through it.) I have always assumed it was the short gas system at fault.

Yes…I do wear Peltors….

I wasn’t referring to the sound. The blast wave of unburned powder feels like a mild TBI if you are close.

Thanks for the intel, post breach/entry…I’ll make a note of it…

*(Short meaning the compromised system in place for the short barrrel -)

The gas bore had to be opened and the rings reduced by a number(?)

Okay, I have been issued a MK18MOD1 for about 6 years now. Have yet to see in any of the the issues you have mentioned rise up. At around what round court do these problems start rising up? I am honestly curious cause it is my job to liaison between our unit armorers and us when deployed or on the road. The biggest problem we have is shooting out our barrels. I have yet to see any mass bolt failure rates, or hammer springs being need to replaced. And what type of flash hider/suppressor or you using to get a mild TBI feeling from.

Longhighwayhome@gmail.com

It appears this data was gained through testing DI rifles. I wonder how much data overlay there would be if compared to Op-Rod (piston) rifles.

These were single shot deals so that none of the gas would be lost.

I’m sure I’m answering my own question here..

I understand that this was done not only to show the harm of short barrels but the increase chance of damage to suppressors, due to higher pressures incurred when running one.. or at least running a silencer on a shorter rifle than it was designed to be used on.

But leaving out the pressure loss from the mechanics of the gas-impingement system, kinda seems like leaving out some important data…

Their data shows a 17,040psi @7inches, which could be the pressure on would experience with the use of a suppressor, but what is that pressure with a functioning gas-system?.. less?..

I understand that even if it’s 17,000psi instead of 17,040psi that doesn’t make it any better..

It was the only part of the test that had me scratching my head.. they loved to point out how STONER built it a certain way.. Well I’m sure STONER designed it to be used with a functioning gas system as well, and to leave it out kinda skews the data..

Piston or DI, it bleeds off a small percent of the pressure, which hotter loads would replenish.

What needs to be pointed out is that this is based on the M855 cartridge. Stating that less than a 14.5 barrel won’t produce optimal lethality is should be expected. Developing a different load for 10.5 barrels is highly indicated, and the first thing to do is not use a military FMJ steel penetrator bullet. If it’s not going to fragment and just poke a hole under 2.400 fps, don’t use it. Use a bronze hollow point designed to expand at much lower speeds, and a powder that isn’t still burning when the bullet exits the muzzle.

If the cartridge and round are a matched set, then the 10.5 needs it’s own complementary load developed instead of complaining the wrong one won’t work well.

So, a heavier Barnes bullet and who’s powder? A little handloading and the answer would be pretty easily derived.

That’s all well and good but most guys who actually shoot pepole get issued ammo from their agency and don’t have the option to hand load.

And this is why agencies should be issuing a round optimized for a SBR if that is what guys are carrying. The MK 318 in use by SOCOM comes to mind as such an example although a LE agency should probably look for a HP round with better expansion.

The m193 is 55grains, ss109 or m855 is 62grains

This explains why M855 is essentially obsolete as a general purpose cartridge, and is nearly the worst option for modern weapons employing barrel lengths under 20″.

I am curious how the M855A1 performs given similar parameters for testing

Doc Dater stated that, “M855 bullets traveling below 2,500 fps when impacting a target will not produce a lethal wound channel.” I don’t think a 20 inch barrel will give you 2500 fps at 200 yards. What does that say about taking back the infantry half-kilometer?

Anyone have any similar articles re SBRs and velocity but with a can mounted- (kind of a blast chambers vs. barrel length).