Duane Dwyer is well known for his association with a Strider Knives. His other project is Summit Materials and he has been working on the HIPTiNite material since 2006. Over the years, he’s given me updates on its progress and now, his patents have been granted, it’s being purchased for use in bearings and the first knives are being manufactured. The specialized commercial interest is really picking up. Imagine a knee prosthesis that never wears out from friction in addition to myriad aerospace and gas/oil industry applications. Amazingly, some of the biggest interest is in the F1 circuit.

All of the materials that are PM grades (particle metallurgy) go through a process involving atomization individually and then as a combined material. They are all combined in a process called Hot Isostatic Press (HIP).

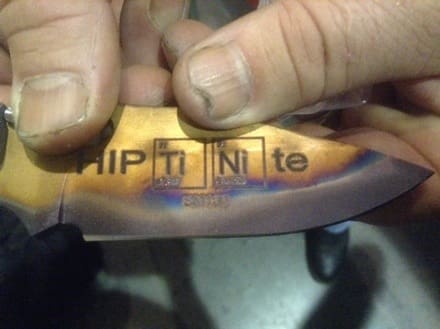

You’ll notice that Summit Materials’ new HIPTiNite material combines this HIP process as well as the atomic symbol for Titanium and Nickel because it’s a binary alloy of nickel and titanium. It’s extremely light and abrasion resistant. That’s right, it’s abrasion resistant. You just don’t normally test metal for abrasion resistance, especially a metal used in knives. In fact, after testing HIPTiNite, NASA had to extend the scale to accommodate the material’s performance. This measurement is called the Model Factor.

It’s the world’s first through-hardenable material to achieve 60HRC+ in a non-ferrous matrix. I asked what it takes to sharpen this material and Duane said, “patience…” He feels that ceramic is the best bet.

Additionally, it has corrosion resistance unmatched by any other hardenable material in history. This includes sea water as well as acids and other corrosives.

Look for a more comprehensive report on this amazing new material next week.