This is a pretty interesting article from ADS Inc regarding the adoption of LED lighting for use by the military. It’s not something I’d normally consider but they make a good case for its adoption when you start to do the cost-benefit-analysis of life-cycle costs.

Automobile headlights, office ceiling lights, shipboard lights, and flashlights are make up the bulk of LED converted lights used in the US Military today. And just like many emerging technologies widely adopted by the military, commercial and residential LEDs have gained popularity in recent years. Regardless of whether you are a civilian or soldier, the common misconception of LED lighting is that it’s more expensive. This case study provides consolidated research that thoroughly examines and demonstrates the benefits of LEDs over its counterparts.

The biggest initial barrier for the widespread adoption of LED lighting (also known as Solid-State Lighting (SSL)) was a purchase price greater than the equivalent Compact Fluorescent Lamp (CFL) or incandescent bulb. SSLs are defined as a light source that emits solid-state electroluminescence through light-emitting diodes (LEDs) and do not use thermal radiation or fluorescent tubes. (Solid-State Lighting n.d.) Since 2000, the Department of Energy (DOE) has invested heavily in Solid-State Lighting (SSL) R&D projects in order to realize the full potential of LED lighting. Finding ways to optimize the use of LEDs included research and development into the reduction of material costs, greater light output, and remedy of underlying technical challenges. As a result of improved technology, the cost of LED lighting dropped almost 40% between 2011 and 2012. (Top 8 Things You didn’t Know About LEDs n.d.)

Cost Comparison

When researching the cost comparison of LED lighting compared to a CFL or incandescent bulb, the question became:

Does switching to LED lighting actually save money, and if so, when are those cost savings realized?

In Cost Comparison (Table A), the cost and lifespan of a single LED, CFL and incandescent bulb are compared. The top-level benefits of using LEDs over CFLs or incandescent bulbs are clear; LEDs cost more upfront but use less energy and last significantly longer.

The real cost-benefit analysis of purchasing an LED bulb over its counterparts becomes clear around the 5-year mark (see Table B – 1 Ballast). At the 10-year mark, CFL bulbs cost two times the amount and incandescent bulbs are six times the amount of a single LED bulb.

How many people does it take to change a lightbulb?

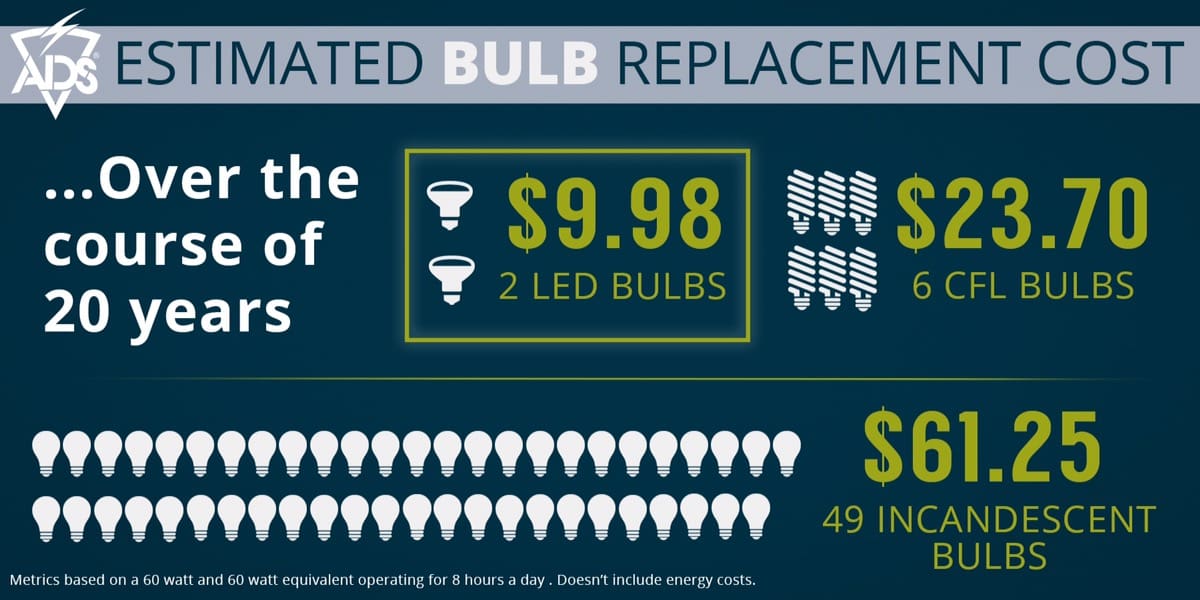

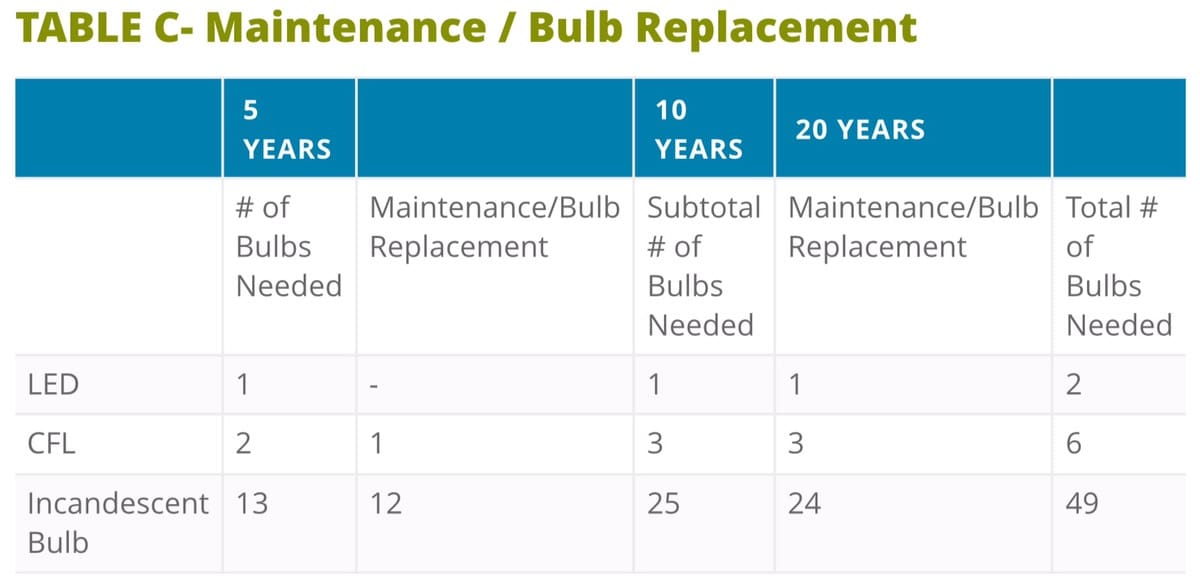

It remains unknown, but what is clear is that LED lighting doesn’t need to be replaced nearly as many times as CFLs or incandescent bulbs. Using Table C – Maintenance/Bulb Replacement, let’s examine changing a CFL or incandescent bulb over the course of 20 years.

You may think to yourself, “Changing a residential light bulb may not require much manpower or preparation.” However, imagine changing a single commercial CFL or incandescent bulb 6 – 49 times over the course of 20 years. Commercial lighting, whether on a ship or in an office, is much more abundant and will require an unwarranted amount of manpower. When lighting requirements are in the thousands, as is with shipboard lighting, changing a lightbulb becomes a man hour intensive exercise.

When you consider the time it takes to replace thousands of commercial bulbs over the course of 20 years, you may be exposing your service men and women to unnecessary risk of injury and countless hours of maintenance that would be better spent on training or fleet operations.

DID YOU KNOWThe U.S. Military has been one of the largest consumers of LEDs sense 1998 (Snyder 2013)

Military Adotion of LEDs

As stated previously, LEDs provide substantial cost, energy, and time savings over CFL and incandescent bulbs. Since the Navy first installed LEDs on ships in 2007, more than 125 ships and submarines – almost half of the current fleet – have been outfitted with more than 500,000 LED products. The Navy’s investment of millions of dollars over the years doesn’t come without a thorough backing in LED research, development and fielding. The Secretary of the Navy (SECNAV) Ray Mabus once stated that reducing just 3% of each vessel’s total energy equates to an annual savings of over $150 million in fuel consumption for the entire Navy fleet. (Shavers n.d.)

According to the Commander of Navy Installations Command (CNIC), energy bills are the single largest cost for Navy installations. Energy costs at one time made up 28% of the Navy’s overall shore budget. It was imperative to reduce these energy costs to free up budget to invest in crucial support training and fleet operations. In 2010, the Chief of Naval Operations (CNO) spearheaded an initiative titled the Navy Shore Energy Program to set specific energy goals geared towards reducing the Navy’s energy costs. The proposed outcome for these goals included reducing the shore energy consumption by 30% in 2015 and by 50% in 2020. (Navy Shore Energy Program n.d.)

Safety and Quality – Added Benefits

In addition to providing cost, energy and time savings, LEDs have been proven to improve performance and safety for our service men and women. Just by reducing the maintenance required, we are mitigating the risk of injury associated with disrupting workflow to replace a bulb. Depending on the mission, having a reliable light source can be critical to safety. Furthermore, the quality of light emitted from an LED creates a “daylight” ambient light that can increase performance and minimize the effects of eye strain, headaches, and migraines associated with traditional fluorescents. Some manufacturers even insist LED lighting can be attributed to changing a person’s mood.

LEDS Lead the Way

ADS is a proud partner and government supplier of Energy Focus, an industry leader in LED technology research and development. Outdated fluorescent technology, whether in a warehouse, on a ship or in an office is proven to cost more, use more energy, require more manpower and strain the eyes. The Energy Focus 2-ft. LED is a direct replacement for these legacy fluorescent lamps, operates with or without a ballast, works with the New Emergency Automatic Lighting System (NEALS), and has a starter that can be removed in either mode of operation. Energy Focus’ technology is the only LED replacement lamp approved by the U.S. Navy for shipboard lighting.

TEST YOUR KNOWLEDGE

Test Your LED Lighting IQ with this QUIZ provided by the Department of Energy.

If you’d like to learn more about LED lighting and other energy efficiency solutions that can save you time and money, contact a knowledgeable ADS Representative at 866-845-3012.

SOURCES

n.d. Navy Shore Energy Program. http://www.cnic.navy.mil/om/base_support/facility_system_investment/Navy_Shore_Energy_Program.html.

Shavers, Lt. j.g. Clyde. n.d. Navy Installations Go T-LED: Replacement of Fluorescent Bulbs. http://www.navy.mil/submit/display.asp?story_id=90427.

Snyder, Tim. 2013. LED Lights Are Now Being Used By The Military. 09 16. http://4wheelonline.com/led-lights-military.231321.0.

n.d. Solid-State Lighting. https://en.wikipedia.org/wiki/Solid-state_lighting.

n.d. The True Cost of Lightbulbs. http://greenlivingideas.com/2015/02/19/the-true-cost-of-light-bulbs-led-cfl-incandescent/.

n.d. Top 8 Things You didn’t Know About LEDs. http://energy.gov/articles/top-8-things-you-didn-t-know-about-leds.

n.d. Wikipedia. https://en.wikipedia.org/wiki/Compact_fluorescent_lamp.

LED light bulbs’ cost effectiveness only holds true if you use quality brands that function for the full lifetime. After trying various brands in my small business, I only trust Philips brand LED bulbs, which have the least failure rate of all the major brands I’ve tried. CREE brand to a much lesser extent. Stay far far away from EcoSmart brand, which has had a 60% failure rate of the bulbs I’ve purchased before ever reaching their min bulb life.

Truth. The race to the bottom applies to LED lighting too. Too many cheap low quality China made brands on the market that doesn’t really improve anything.

Done right it should increase floor brightness while cutting down on consumption.

The issue always left out of these “analyses” is the quality of power being applied to the fixture. I live in a major metropolitan area and LEDs burn out at the same rate as the incandescents.

When power-based burn out rates are included, the LEDs/fluorescents are not nearly as good a deal. As JKATX points out, the original quality of bulb manufacture makes a huge difference; the crap sold by Costco (and others) is ultimately expensive junk.

Another thing always left out is the cost associated with the manufacture _and_ disposal of the bulbs, along with the V/AC use associated with cooling the electronics upstream from the bulb. AC/DC conversion is typically Stupid Inefficient, and you can’t suspend the laws of physics. As a true cost function, LEDs don’t save any money, they simply shift cost.

If they don’t have a chart showing how many Squids it takes to change a lightbulb, they failed miserably….

Those are full-fledged “Infographics.”

And yeah, that would be funny to see…

Great article, thanks for posting this.

A friend owns a swimming pool business with two showrooms in different towns. When they converted over all of their old style lights to LED, they dropped their electric bill by ~$400 a month as compared to previous years. On its face, that seems worth it.

That’s an amazing immediate return on his investment!

Another benefit of LED bulbs is not having to drag out the ladder to get at the PITA fixtures to replace burnt bulbs every month or two.

And who will be sourcing these LEDs ? The ChiComs I’m sure, eh ?

I am a frequent reader and also working on a side business to provide quality sourcing of commercial LED lighting. Would it be appropriate and permissive of me to post a link to the company website?

Go for it

This is great news! I can’t even begin to remember how many broken light bulbs we had in our light sets for the BN Aid Station.