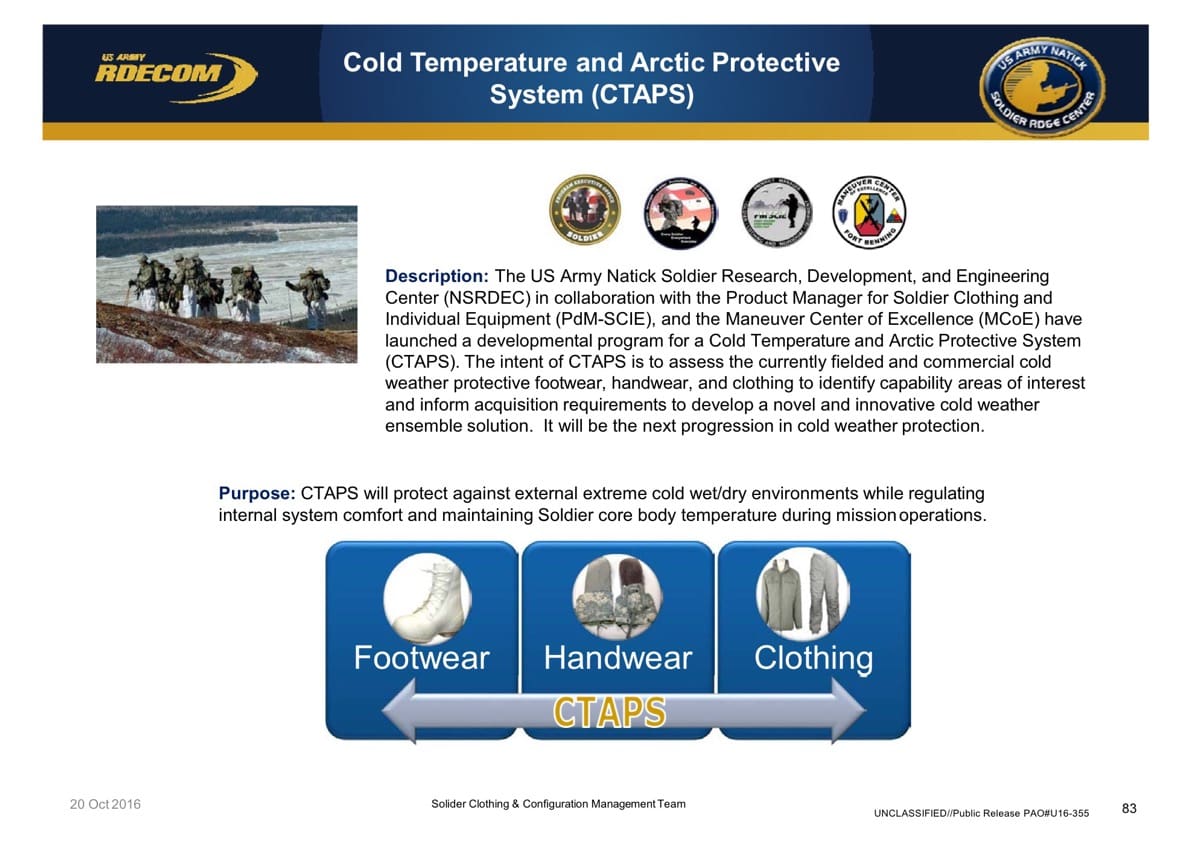

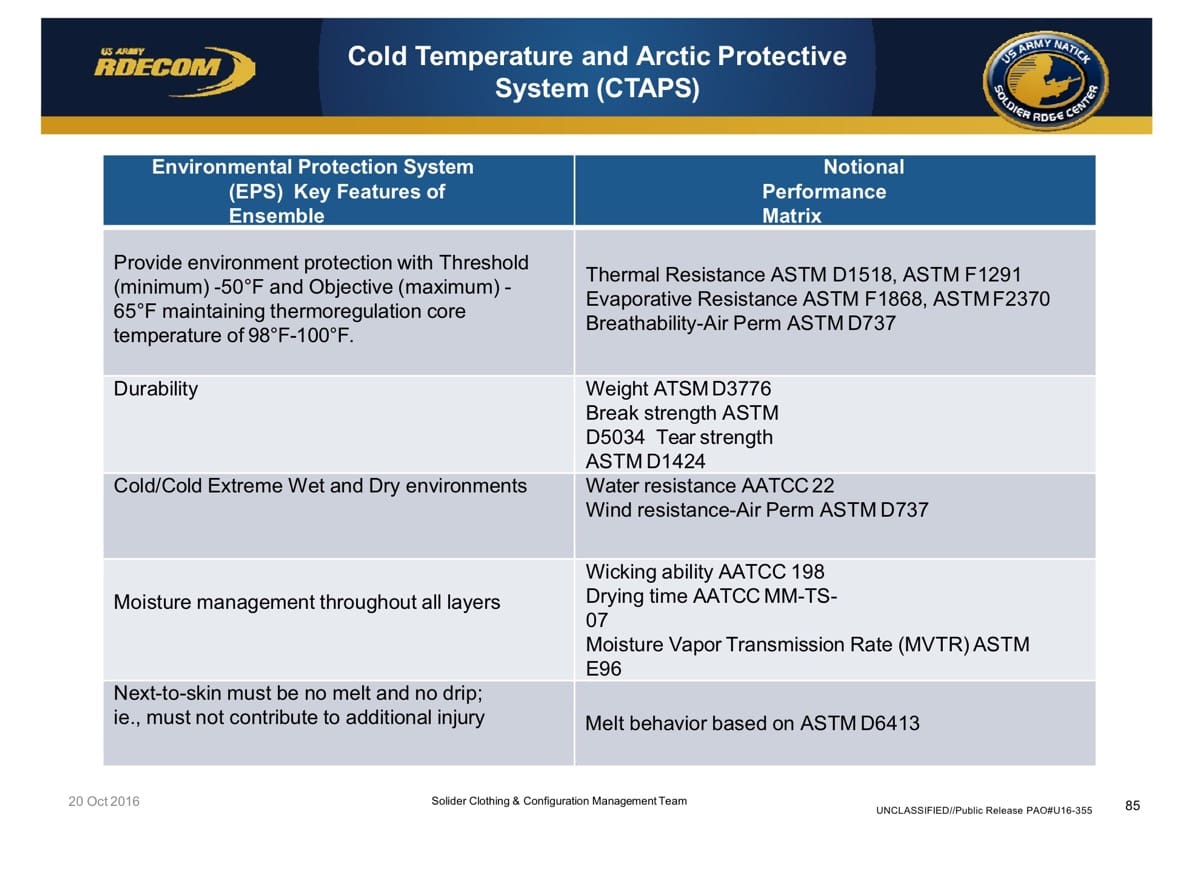

The U.S. Army Natick Soldier Research, Development and Engineering Command (NSRDEC), Natick, MA is conducting a market investigation to identify domestic suppliers and manufacturers of potential sources for materials, individual garment items and complete clothing systems for the development of a Cold Temperature and Arctic Protection System (CTAPS). This RFI will exclude handwear and footwear. The effort will develop a multi-layer system that will provide a minimum of no melt and no drip next-to-skin layers, environmental protection from wind and water, and provide tailorable protection for temperatures spanning a range from 45 Deg F to -65 Deg F in as few garments as possible. Essentially, it’s a replacement for Extended Cold Weather Clothing System (ECWCS) Generation III which is an adaptation of USSOCOM’s Protective Combat Uniform.

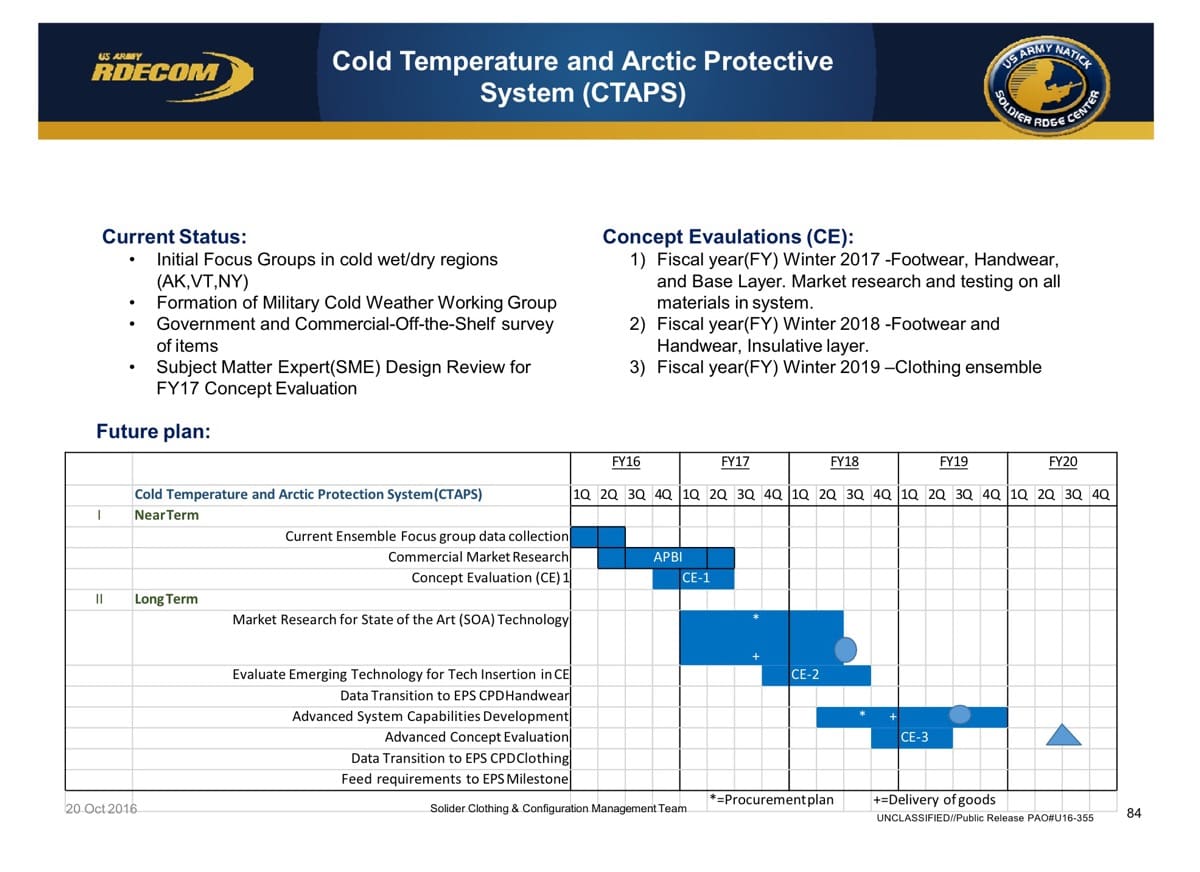

Here are some slides from late last year describing CTAPS. You’ll also notice a reference to “Environmental Protection System,” an overarching program, of which CTAPS is but one component. For example, there will also be a hot/wet aka jungle component of EPS.

According to the RFI, new cold weather materials, end items, and systems should be light weight with better durability, provide high compressibility/good recovery for packing in the ruck, have improved moisture management, and be fast drying while maintaining insulation. The performance of the current seven layer (it’s actually levels not layers, but the RFI refers to them as layers) ECWCS Gen III is the baseline for characteristics and protection upon which materials, individual garments, and complete clothing systems will be compared. The individual garments or layers of the clothing system can be categorized into three areas: base layer (next-to-skin), insulating layer, and outer shell. While flame resistance is not a requirement at this time, materials and items that are flame resistant will be considered. It is also desired to expand no melt/no drip performance beyond the base layers without negatively impacting other performance attributes.

The Government will require 90 days after the 21 April 2017 submission date to make an initial assessment of the proposed technology(s) potential to fulfill CTAPS needs. The Government will integrate selected technologies and designs into test garments for field evaluation in winters 2018 and 2019 to establish operational effectiveness and Soldier acceptance. A test method matrix upon which materials and/or end item garments and systems will be evaluated is attached. Concurrently, NSRDEC will be seeking test methods to better predict operational effectiveness in the field. The Purchase Descriptions of the current ECWCS materials are available upon request. Interested sources may submit any combination of material samples (textiles), end item samples (garments), or complete system samples (ensembles) along with technical information as outlined in item (a) below. The samples will be degraded or destroyed during evaluation and will not be returned to the vendor. If a source chooses to submit samples, no payment will be made by the Government for such samples.

I’m glad to see the government going at the RFI in this fashion. This way they can take a look at best of breed in each category. Unfortunately, when full systems are evaluated against one another, costs are easier to anticipate and control but individual components may be wanting. Natick has been briefing this program since last Summer’s OR and while everyone in industry is excited, there has been some hesitation over the Army’s intent to own the IP for any solution it adopts. This may preclude some of the best solutions from being submitted.

For full details, visit www.fbo.gov.

“This RFI will exclude handwear and footwear. “???

Where is that going to come out….

I figure it has something to do with the fact that they have glove systems from Outdoor Research already which span a pretty large temperature range. No clue on the footwear though.

The footwear portion is currently under evaluation through a separate program, as are the gloves.

Actually the OR glove systems are not Army programs of record. There are multiple purchases out there but the Army has significant issues with gloves and boots.

http://www.watertowndailytimes.com/news03/fort-drum-to-receive-125-million-in-cold-weather-gear-after-being-declared-an-arctic-zone-20170125&template=mwdt

Wont the army just take the IP anyway when they have someone else knock it off for them?

I notice that there’s no mention of any kind of camouflage outer / over-layer.

Is that because the Army thinks that cotton parka shells from the 1950’s are good enough, or because a camo solution is part of a different work stream?

The OR glove suite is an issued package across SOCOM, but big Army doesn’t provide them.

The ECWCS is an excellent all-weather system, I’m curious to see what big Army looks at to replace it, as well as what true advantages there are? I know that SOCOM fielded the new PCU which has three level 3s (fleece, loft, loft with DWR), that might be an option worth looking in to. I can’t help but feel that someone in the Army has experience with cold weather gear, hopefully this takes their input into account come selection time.

The footwear and gloves are being evaluated under separate programs.

The Marines and SOCOM field variants of the OR glove systems, but the Army hasn’t bought in yet. Per my conversations with the PM’s, they are moving that way though.

VB boots are fielded and also available to order through DLA and there is a new boot currently being evaluated to replace or supplement them. The biggest issue with cold weather footwear is that there is a capability gap between the Intermediate Cold/Wet Weather boot and the Extreme Cold Weather boot in the 20*F to -14*F range. Both Natick and the Marines are working to fill this gap, but they need support from industry to do so.

They need to be realistic.

They do, but we all know that that isn’t their strong suit.

How much do you want to bet that the Norwegians, Swedes, and Finns, and all the Alpine countries too, all have decent cold weather and extreme cold weather footwear? Do we really need to reinvent the wheel here?

To make it Berry compllient they do sadly.

Berry means it just has to be made here, from American materials right? Shouldn’t stop a European boot company from being able to set up shop here and make their design in the USA should it?

No, but that’s much easier said than done.

Aren’t there also primaloft booties issued with the marine happy suit? I think the canadians and norwegians use a mukluk style over boot. Maybe that would be an option to cover gaps/ extend ranges of different boots.

Have you looked at “Wiggy’s” (www.wiggys.com)? When I was stationed in Alaska (4 years) we used Wiggy’s sleeping bags and they were excellent. They rolled and compressed very tight; lightweight to carry and I tested it personally at -64 for two days in a row and I stayed warm. No need to reinvent a wheel when the SEALs and Air Force in Alaska are already using them.

They don’t compress well.