October 2017

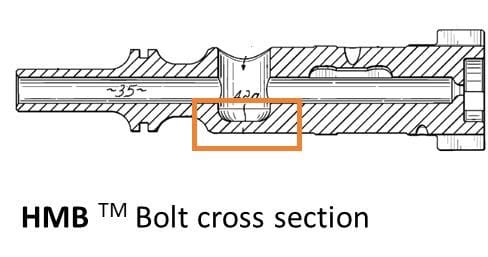

Mt. Orab, Ohio – HM Defense announces the release of its all-new HMB Bolt, an enhanced durability bolt for M16, AR-10 and AR-15 rifles. The HMB Bolt corrects a natural weak point in existing Mil-Spec M16, AR-10 & AR-15 bolts where the cam pin hole passes through the bolt. Under extensive use, including the stress of combat, a standard Mil-Spec bolt can fail at the cam pin hole location.

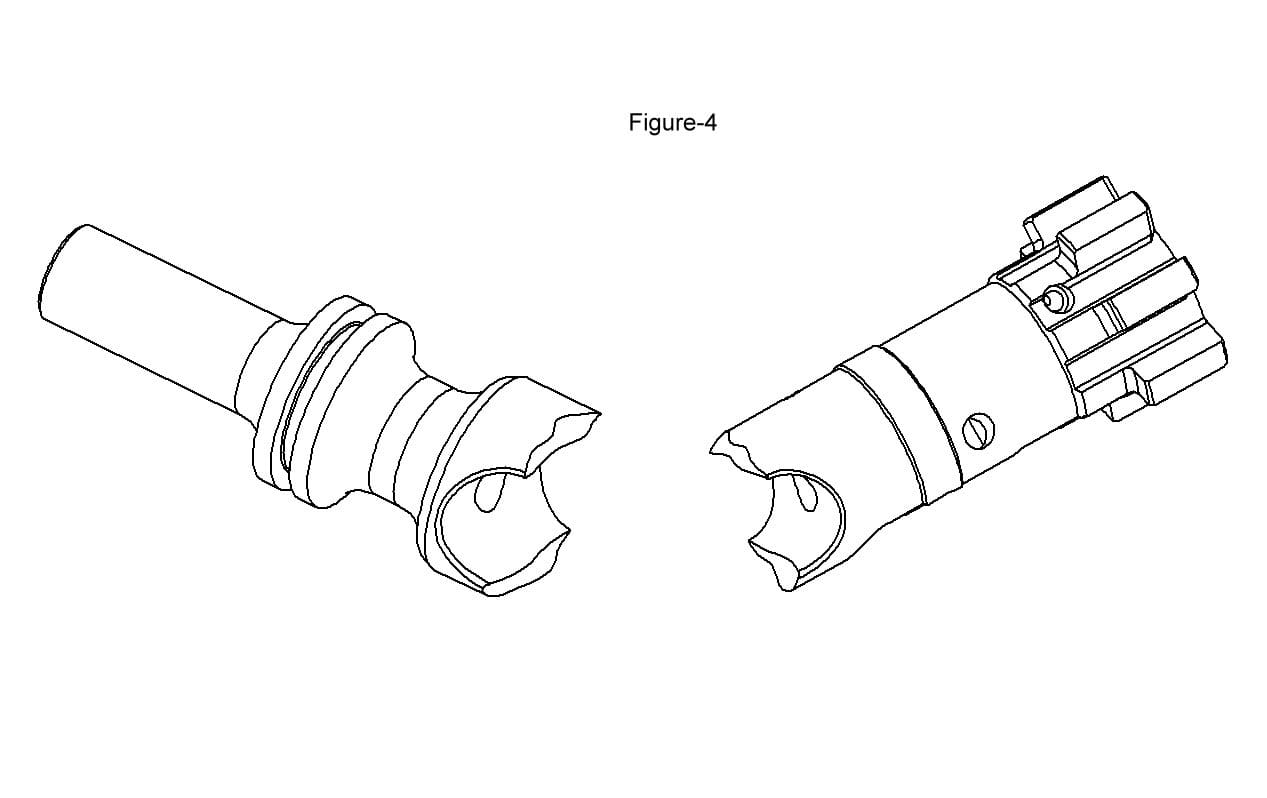

The HMB Bolt by HM Defense eliminates the pass-through cam pin hole and replaces it with a cam pin socket and tapered cam pin design. This new patent-pending design eliminates the natural weak point of Mil-Spec bolts by significantly increasing the amount of metal (and strength) at the cam pin location. The result – No more broken bolts!

“The HMB Bolt design provides a substantial improvement in long-term durability over the existing Mil-Spec bolt,” said Clay Barker, General Manager at HM Defense. “Every M16 and AR rifle can benefit from our new HMB Bolt design.”

Additionally, the HMB Bolt reduces contact between cam pin and firing pin, enabling smoother operation of firing pin, bolt lugs and aft gas rings. The new cam pin socket also retains lubrication for extended operations.

The HMB Bolt is 100% compatible with Mil-Spec M16 & AR-15 BCGs and can be installed as a drop-in bolt replacement in any existing M16 or AR-15 rifle. The HMB Bolt will be standard on all HM Defense HM15 rifles and available as an HM Defense bolt replacement kit or in a complete. HMB Bolt Carrier Group starting in September 2017.

For more information on the HMBTM Bolt and other HM Defense technologies, please visit www.hmdefense.com

Tags: HM Defense

Yawn… Lets revisit these in a couple of years if HM is still in business.

They won’t be… not with this product, at least.

Did a little FEA after speaking to my friend and long-time gunsmith about this; the reduction of bearing surface on the cam pin is just going to make the cam pin fail (faster). Yeah, the bolt might not split, but trading one total failure for another isn’t a good deal.

If anyone doubts this, just pull apart a short-barreled AR and look at the cam pin wear and tell me you think removing more of the bearing surface is a good idea.

Not sure how much of a load the cam below the firing pin takes. Almost all of the wear on my cam pins is above the firing pin. Interesting idea though. Every bolt I have broken has been in the lug area (Grendel and Beowulf bolts)

For my education, does anyone know why there is a cutout ahead of the gas rings? I thought the tail up to the rings formed the front part of the piston. Why isn’t the bolt body straight up to the cam hole like the HK bolts?

A little clarification on my question. Why is there a smaller diameter “waist” ahead of the gas rings?

In simplest terms this is where the gas port ends under the gas key. It provides an area for the expansion of gas. On an AR18 and 416 bolt, which are piston driven of course, the “waist” doesn’t exist.

Not quite correct, the boat tail of the bolt is where the gas port ends. http://oi45.tinypic.com/15p01fk.jpg

Negative… You’re on the wrong end. Who knows what the waist area is for. Debris clearance, weight, whatever you want it to be for…

The cam takes quite a big load. Cam pin lash can be a problem if your barrel has a larger than customary gas port or you’re running suppressed.

The spec for the cam pin diameter and the hole in the bolt are nearly the same. To speed production and reduce returns, most manufacturers make the hole in the bolt to big and the pin to small.

When the pin is too small and the hole too large, the unlocking force isn’t lateral to rotation of the bolt and the pin rocks in the bolt hole. This leads to impact between the carrier and cam pin.

I doubt this design will prove to be anything more than a gimmick.

I’ve used an M16A2-M4A4 for 16 years as well as being a marksmanship instructor and aboard Wilcox range at Camp Pendleton amongst 500 Shooters on many occasions. I’ve never seen or even heard of a broken Mil-Spec bolt.

Depending on the price, I’m pretty pumped to try them. Just broke two of these a couple months ago. Granted, by the time the bolts broke, several other internal parts were reaching their life cycle.

I’m having marketing flashbacks to the Sharps Reliabolt.

poor design. they must have outsourced this engineering shit to India.

So let’s make the cam pin even weaker to strengthen the bolt.

Y’know…

Working inside the envelope of existing design that is the AR15 family of weapons, I’m really not too hepped up on trying stuff like this. You want a stronger bolt in that area, without compromising the cam pin strength, well… You need a bigger bolt. Which means you need a bigger carrier, which means… Well, you basically need a whole new gun, to balance everything else out in the design.

Question I’ve got for anyone out there with experience in other weapons that actually see high use, and which use the Johnson-style rotating bolt: Do the bolt fail in similar fashion, or is this unique to the AR-15 series? I’m thinking of the SA80, and the various other non-Stoner impingement designs like the Daewoo K2 and the Taiwanese piston guns. Be interesting to know, that.

I honestly think this is addressing a non-existent problem that would be better dealt with by either sticking with milspec bolts in the first place, or paying some actual attention to the replacement schedules for your parts on high-use guns.