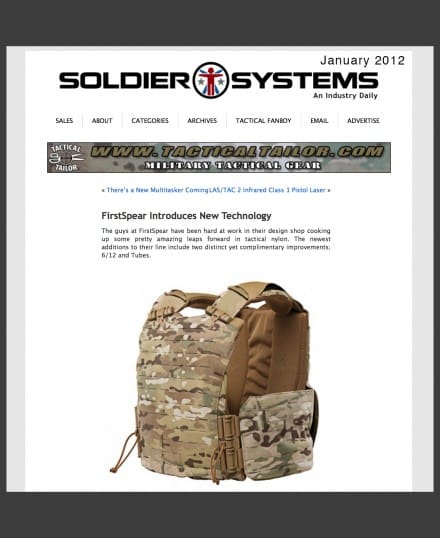

In January 2012 FirstSpear introduced the first production tactical vest with a laser cut MOLLE compatible platform along with Tubes, a new standard for rapidly donning and doffing ballistic protection. Since then the technology has been fielded with assets of the United States Department of Defense, State and Federal Law Enforcement Agencies and early adopters from the international special operations community.

Ronnie Fowlkes, VP Business Development – “Everyone said the technology wouldn’t work when we first released it and thought we were crazy when we said we were discontinuing MOLLE permanently. Now, everyone else is trying to catch up and move this direction.”

Today, we take a look at some of these vests after more than five years of continuous field use.

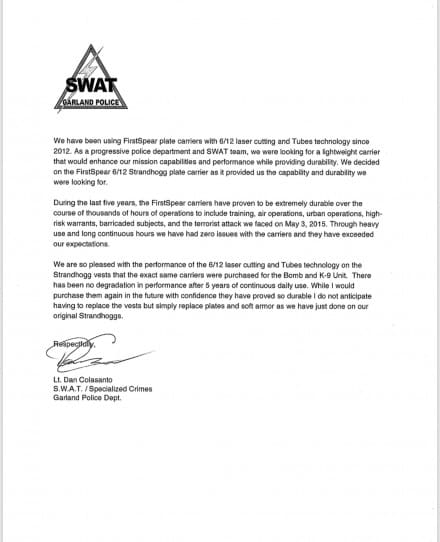

Lieutenant Dan Colasanto heads up the Garland Police Department and SWAT Team and was one of the first teams to test, evaluate, and field the original Strandhögg plate carrier system more than 5 years ago. Those original vests are still in service with the Garland PD today. According to Dan, “Through heavy use and long continuous hours we have had zero issues with the carriers and they have exceeded our expectations.”

We have been FirstSpear customers since the company started. The 6/12 system provides superior performance and durability compared to other carriers I have used in my 25 years of service in law enforcement and 22 years of SWAT. –Lt. Dan Colasanto – Garland Police Department

Tubes single hand operation was a game changer all on its own and the perfect complement to 6/12. When the two technologies are used together they can afford the operator about 40% reduction in weight compared to vests with the same features.

With increased demand from end users and adoption by operators within the US DOD, FirstSpear has agreements in place with industry leading manufacturers and OEM partners to license FirstSpear laser cutting technology and integrate Tubes into systems supporting the warfighter, law enforcement and security professionals. An enormous amount of energy was put forth to bring these disruptive technologies to the front lines and FS welcomes additional equipment manufacturers to expand upon the success of Tubes and laser cutting technology for their own equipment solutions.

Scott Carver, President & CEO – “After years of investment and development in new technology, we’ve demonstrated lighter weight, improved performance, and now real world durability at a level never seen before. In an effort to get this technology to the men and women who need it as rapidly as possible, we are actively working with other domestic manufacturers to help them integrate laser cutting and Tubes in to their vest systems.”

FirstSpear was founded in 2010 by a team of former service members and industry professionals dedicated to building the most advanced load bearing equipment and armor platforms for todays armed professional.

Tags: FirstSpear

While the Tubes buckle is a unique ‘BUCKLE’ it is hardly a release system… each buckle must be manually triggered to release the carrier… very cool in concept but difficult to re engage when loaded down. IMO

I disagree with you sir. We have been using the FS Strandhogg as our primary armor kit since mid 2013. The Tubes release and reassembly is exceptionally efficient. So much so, that we are in an evaluation process to replace our armor kits, and our 34 man team unanimously voted that the only option would be another FS Tubes based system.

From a lowly medical perspective this system is amazing! With one simple gross motor skill set, I can open the carrier and began to access my patients. I wish that the conventional forces would adopt this system to all of our war fighters. As for reengaging the system I find no difference if the system is loaded or not, its still simple and easy to use system. Now if your inference is to a single point “blow-out” style release, no this is not it and I’m grateful for it. I couldn’t tell you how many times my IOTV “released” and I needed an engineering degree and about 30 mins to put it back together. The tubes system with the new upgraded cummerbund is the best system I have seen and worn to date.

In my experience in the military the single action rip cord release was difficult to work with, especially when putting it back together. I am currently using the F/S Tubes system. My gear is fitted with the Tubes system. I no longer have to mess around with Velcro straps to make sure that the weight of my kit is evenly distributed every time I put my kit on.

I was also never a fan of Velcro due to the noise and how quickly it would wear out and fray.

James we assume you have had a chance to try out the Tubes first hand? The muscle memory used everyday to take the vest on and off is the same movement required to ditch your armor during an emergency and even get it back on if possible, all in a few seconds with a very low profile and extremely secure design, purpose built for releasing plate carriers. This video shows how easy it is to manipulate one handed with mags inside the cummerbund.

https://youtu.be/vkDMbq9x9os

Yes I have had the opportunity to use a carrier with the Tubes buckles… while I have not discounted its functionality… it is a buckle… NOT a release system. again my opinion.

james, you are right that it’s not a traditional quick release system, it is a buckle. If someone asks for a one handed (single action) quick release system, then Tubes wouldn’t be it. Crye Precisions release for the JPC 2 also requires 2 actions at minimum, so it seems to be that the one handed (one action) requirement have gone away in circles that used to require it.

The main thing that I don’t like about them is that they take up space in what I consider the important areas of a vest. And that squeaking sound.

Raine made a Tubes cover that fixes the lost MOLLE space issue.

I got to try it at Shot Show and it’s good to go. Bought one from the Kickstarter they did last month for my Strandhogg.

I think you can pre-order now from the same page:

https://www.kickstarter.com/projects/256206016/molle-cover-for-tubestm-cummerbunds-plate-carriers

That squeaking sound was only on the Gen 1 tubes, and i believe they offered a recall and replacement.

Been amazed by your guy’s gear since I was stationed at FLW and drove by in STL. Are you planning on making any more FirstSpear STT carriers for SKD? Love the Strandhogg but its a little outside the budget for a lowly Sapper like me.

We have been using this for our DEA Clandestine Lab Team for about a year now and we are all very pleased with their design. Like Steve T said earlier, the ability to get it unbuckled with a pull of the cord up or down makes it a lot easier to provide care to the chest/torso area without having to cut the vest. We have about 30 of them and I haven’t had a single complaint.

And i know i also had some initial issues with getting the tubes to release, but its only because i initially thought i was skinnier than i actually am. Once i had it sized appropriately, the tubes worked perfectly and the vest remained securely in place. The 6/12 system blows Molle out of the water.

DHSCBPSOG teams are issued these PC’s and love them