We received this note from? Forward Thinking Solutions regarding their 3D Printer File For Valve Covers for 3M Masks.

The Cover-Inhalation Port, Gen 4 (CIP-Gen4) is a bayonet cap that will shut off one of the two inhalation ports on the 3M 6000 series half face respirators. Given current circumstances affecting the world, PPE, and especially respirators have quickly become high need items that are in limited supply. While there are better gas masks and tactical respirators, the 3M 6000 series half face respirators are extremely common and many people already own one in their workshop. Made from silicone, these 3M respirators are far more comfortable than the sharp-edged N95 Particulate Respirators we see cutting into the faces of the hard working health care specialists and first responders on the front lines of the pandemic. The 3M 6000 series masks are first and foremost designed for comfort, protection and breathability. But due to their dual filter cartridge design, they’re not ideal for someone who may need to shoulder a rifle. The mask’s filter cartridge on the shooter’s dominant side always impedes a natural presentation of the rifle’s optics.

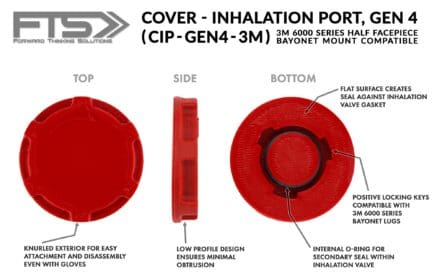

The goal of the CIP was to block one of the two inhalation ports securely, while also being minimalist in profile. We certainly weren’t the first to conceive of an inhalation valve cover. 3M makes a port cover (part number 6880) but they are limited in availability. Others have put out their own versions of a 3D printable port cover, however many of the ones we‘ve seen are not as low profile as we desired.

The CIP-Gen4 is the forth revision of our current design and features:

• Knurled outer perimeter to aid in installation and removal

• Low profile design

• 3M filters are always sold in pairs. Using just one filter cartridge means you can make your filter cartridge supply last longer

• Inner plug* with an o-ring for additional sealing

*The CIP inner plug’s o-ring is optional. Once the CIP is locked down into the mask’s inhalation valve’s bayonet interface the flat bottom face of the CIP forms a seal with the inhalation gasket. The o-ring just provides a secondary seal and therefore additional protection (Note: the CIP’s o-ring is optional, but the orange OEM 3M inhalation-port-gasket ring MUST be used). O-ring size is dash 112 (we’ve been using nitrile o-rings, silicone are probably fine also). You can size up or down if you find the fit with the o-ring to be loose or too tight. We’ve seen slight tolerance variations on the 3M 6000 series mask over various years of production.

FTS has uploaded the CIP’s 3D design on Thingiverse, free for anyone to download and 3D print. If someone doesn’t have a 3D printer they can have a 3rd party company like Shapeways 3D print it for them. When printing the CIP it is highly recommended it is printed using an antimicrobial filament. If printed with a filament material like PETG it’s recommended to wash it occasionally with soap+water (or just dunk it in alcohol) and then allow to dry to ensure any bacteria build up is eliminated. If 3D printed on a SLS type printer be aware that those printers leave considerable nylon dust in the recesses of the printed part and will require thorough cleaning to ensure that’s not particulate you’re inhaling. For obvious reasons, you shouldn’t print these with carbon fiber filament or any other material harmful if inhaled.

As with any PPE, you will need to test it throughly first each time prior to use to ensure an appropriate seal and function is present.

All our best to the first responders fighting hard everyday for the rest of us.

Thank you. Truly.