Groundbreaking technology expands production capacity in response to firearm industry demand

MENOMONEE FALLS, Wis. (February 25, 2021) – Vortakt Barrel Works announced today that it is adding a fully automated manufacturing cell to expand its barrel blank production capacity, further improving the level of support offered to OEM firearm manufacturers.

“The market for firearms has seen incredible growth throughout 2020 and into 2021. Vortakt’s close working relationship with our sister division UNISIG allows us to rapidly expand our production volume to meet market demands. Adding this new automation cell is just the next step in our continued march toward unparalleled manufacturing excellence.” said Chad Weister, Division Manager of Vortakt Barrel Works.

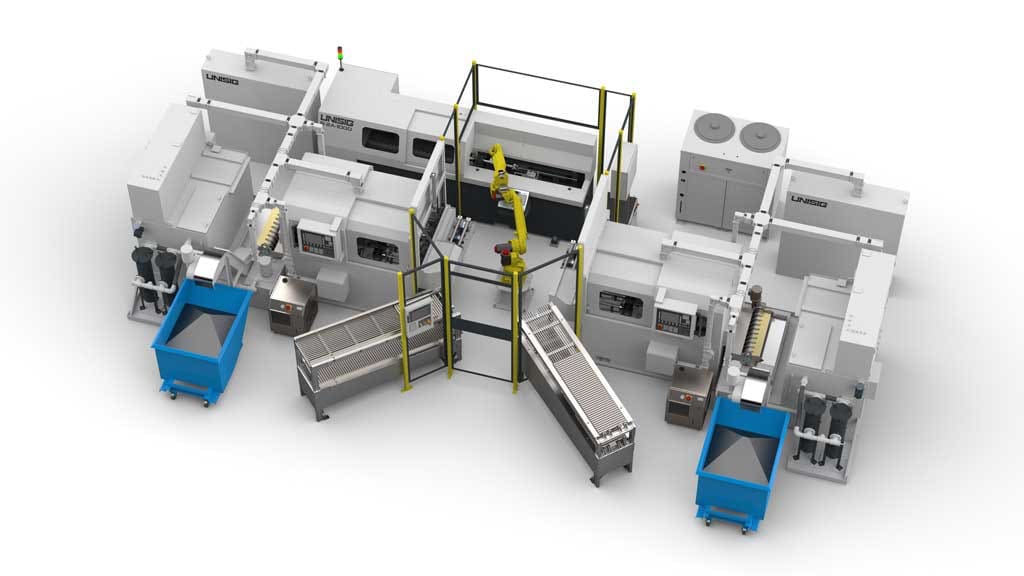

The manufacturing cell is designed to improve upon the barrel blank manufacturing process and incorporates the following machines:

• Two UNISIG UNI-10-4-2i-450-CR Gundrills, each with 2 spindles to drill and ream barrel blanks, enabling all 4 spindles to run simultaneously.

• One UNISIG R-2A-1000 Button Rifling machine designed to function in tandem with the gun drilling and reaming operations.

• A Fanuc M-20iA Robot to transfer blanks from a drop-in feeder through each operation with engineered precision while also handling rifling tool exchange between each barrel blank, eliminating the need for any manual material handling.

With robotic automation driving the production process, the new manufacturing cell will be able to manufacture thirty barrels each hour, for a total capacity exceeding 3,600 barrels per week. The cell is designed to accommodate the most popular pistol and AR-15 barrel designs currently on the market.

For more information on Vortakt’s new fully automated manufacturing cell, visit vortakt.com/automated-manufacturing-cell.