The US military is going through a massive transformation, standing some organizations down while creating entirely new ones while simultaneously fielding new systems.

This can cause some serious headaches for those who have to bed these units and systems down. One of the capabilities that arose during the past 20 years of conflict is expeditionary shelters which are almost as good as permanent structures and will last a decade or more. They offer a great solution for pressing needs. What’s more, they can be acquired using O&M funds.

In addition to storage for new equipment and structures for units, they can be used for rotational forces in forward areas where permanent structures would take years of negotiations and construction to complete.

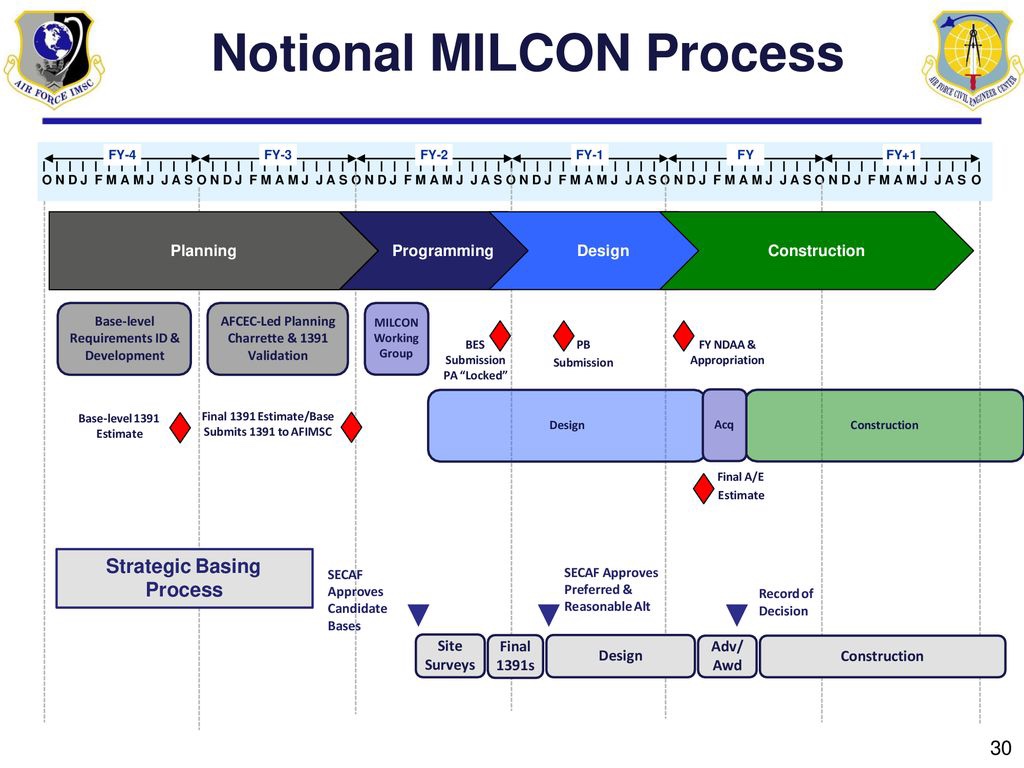

Military Construction or MILCON in DoD jargon is responsible for Facility Planning, Design, Construction, Modernization and Sustainment. It is understandably difficult to pursue because it is a multi-year process involving all phases of construction from establishing a need to finishing up the punch list to disposing of an unneeded facility. New construction must be included in the National Defense Authorization Act to be funded so politicians also get involved. When it involves construction on foreign soil, the complications increase, even if they offer to pay.

As you can see from this Air Force slide depicting a notional MILCON project, it is a minimum of five years until the project is completed. Worse yet, the project may sit on a wishlist for several years before this process starts and it is even considered.

I’ve had my own run-in with the slow process of MILCON. While assigned to the 21 STS at Pope at the turn of the century, we were handed the keys to a brand now Squadron facility. Totally new construction, built specifically for a specific need. The problem was that it was designed for the 23 CCS, a unit that had been moved in the ensuing years between approval and construction from ACC to AFSOC. In the meantime the unit had doubled in size with the addition of Pararescue and enablers and its beefed up its complement of Combat Controllers. This consolidation of Combat Control forces across the Air Force to AFSOC had happened several years prior but the MILCON process is so plodding that it couldn’t keep up with a service in transition.

Since I was the sole support Captain in the Squadron, I was given my marching orders by the commander to start the paperwork for additional MILCON. It would be years, if ever, before relief would come. You can see the building on Hurst St on Pope Field, just to the right of the fuel tanks in the Google Earth image above along with the construction just north of the building which we occupied in 2000.

The image is from this year. I started the paperwork in 2000 and retired in 2006. We sure could have used some of the shelters seen erected in expeditionary environments to house elements of our Squadron and its equipment.

Others are already doing it. Expeditionary shelters started to pop up on several facilities in support of physical fitness training.

They’ve also been used for vehicle inspection and maintenance activities. There is a lot of capability available with multiple types and sizes of shelters as well as associated amenities like flooring, lighting, HVAC and furniture. Additionally, there are storage solutions for use inside the shelters like Spacesaver Storage Solutions.

Types of shelters include rigid wall, expandable, soft sided tent-style, and even shelters based on shipping containers. Need to stand up a full-time Operations Center for distributed operations? There’s a solution for that.

Check with ADS for your next shelter requirement. Their expert team can design a custom solution to meet your specifications, budget, and timeline. Utilizing the speed of other contract vehicles and the experience of industry-leading suppliers, ADS can complete deliver a built-to-order product in a fraction of the time of a standard MILCON project.

I know this is pretty much for ADS and I get it, I have worked with them a lot and they are great but if a unit cannot go to an outside contractor, Force Provider is a really good alternative. They are quick to react, easy to move/setup and quality products.

Eric your personal story was a good share here. It’s incredible that 20 years later the DoD is just getting around to constructing that building. With that in mind, this type of product is a no brainer. Kudos to the group that answered the call and designed that shelter product.

The new construction at the 21 was completed recently. It is still not allowed to be utilized due to proximity to the train tracks and Bragg has rules in regards to that. The bldgs are also sized for the old SQ footprint which was outgrown years ago. So essentially the MILCON was a waste of time and money.

It’s like a broken record. Sad.