ABERDEEN PROVING GROUND, Md. — Underbody blasts from improvised explosive devices were the largest cause of injury for U.S. troops in Iraq and Afghanistan This signaled a vital need for an anthropomorphic test device, or ATD, to replicate the response of an underbody blast environment on Soldiers.

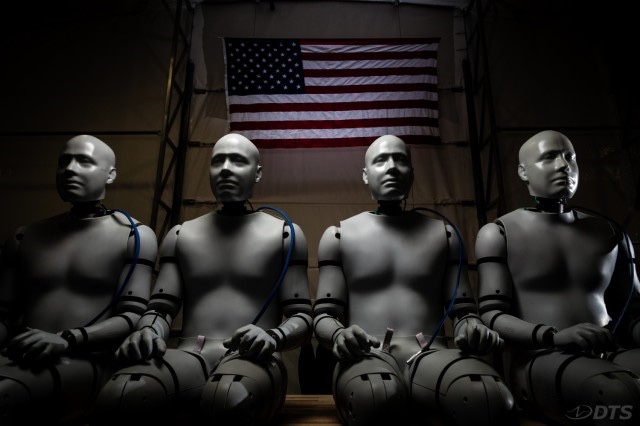

The Warrior Injury Assessment Manikin, coined WIAMan, filled that need. WIAMan is an ATD for military use in underbody blast testing of ground vehicles. Developed by the Instrumentation Management Office at the Program Executive Office Simulation, Training and Instrumentation, WIAMan represents the most human-like surrogate yet to provide insight on improving military ground vehicle systems and identify protection mechanisms that reduce the likelihood and severity of warfighter injuries.

Analytical experts from the U.S. Army Combat Capabilities Development Command, or DEVCOM, ensure that WIAMan output is processed to provide reliable injury assessment and analysis. The DEVCOM Analysis Center, known as DAC, processes this immense amount of data via a software analysis tool known as the Analysis of Manikin Data, or AMANDA. On Feb. 2, AMANDA was accredited by the U.S. Army Test and Evaluation Command for use in live fire test and evaluation — a final stamp of trust in quality and accuracy.

According to Kate Sandora, AMANDA model manager, AMANDA’s most recent release and accreditation is a culmination of a large effort by DAC and its partners, encompassing all WIAMan injury criteria developed over ten years of biomechanics research. The accreditation provides more confidence for the live fire testing community and current users, including DAC, DEVCOM Ground Vehicle Systems Center and the U.S. Army Aberdeen Test Center.

AMANDA is not a single injury model, but an analytic framework composed of multiple types of injury criteria and reference values integrated together. AMANDA processes accelerations, forces and moments recorded by WIAMan and other ATDs as input, comparing the ATD data with associated injury criteria to make predictions of injuries and determine the injury type, location and severity. AMANDA can also read in and process simulated data in lieu of physical testing.

While WIAMan is the hardware subjected to the blast event to record data, AMANDA is the software allowing the collected data to be processed for analysts’ use, pre-loaded with accredited criterion for injury. The resulting analysis has significant impact on Army vehicle design to improve survivability when Soldiers are subjected to an underbody blast environment. Simply put, insight from AMANDA saves lives.

“The WIAMan data acquisition system takes samples from an event at a rate of approximately 200,000 samples a second, and the typical event takes a couple seconds, so we’re talking around 400,000 data samples — an incredible amount of data,” said Jacob Ehlenberger, AMANDA software developer. “When you load that into AMANDA, all subject matter experts have to worry about is looking at the results. AMANDA automates the entire process, bringing complex analysis to the hands of experts so they can focus on their domain of excellence.”

AMANDA also integrates filtering methodology, developed by Aaron Alai, a DAC signal processing scientist, to ensure sensor data does not reflect extraneous noise that could lead to incorrect injury prediction.

“A common misconception is that sensors and data acquisition systems measure only what one intends for them to measure, but in reality, they respond to anything that can influence the measurement pipeline: a litany of sources from electromagnetic noise to mechanical linkage vibrations. So, data must be filtered to glean accurate information,” Alai said. Alai leveraged frequency analysis to come up with a new method of inferring appropriate filters, working with Ehlenberger and other DAC teammates to ensure they are implemented and contextualized properly.

DAC analysts can then more reliably provide injury assessments that inform vehicle evaluation, design and requirements to better protect Soldiers, bypassing time-consuming manual data manipulation.

Sandora and Ehlenberger, who have worked closely with both analysts and developers of the design and standards for WIAMan, commend the experts’ diverse perspectives to make appropriate injury assessment possible. “You have subject matter experts in the field of human vulnerability working in close contact with engineers of high caliber discussing the ATD experience and mechanical response,” Ehlenberger said. “It is such an impressive marriage of distinctly different and invaluable expertise.”

It is through extensive testing and problem-solving from these experts that WIAMan can produce data to feed AMANDA analysis, ultimately enabling the Army to better quantify risk to the warfighter and identify trade-offs during vehicle design. This analysis ensures growing Army knowledge in human vulnerability and automotive design — and soon, even more, as AMANDA will be integrating more WIAMan injury criterion this fiscal year.

By Kaylan Hutchison, DAC Strategic Communications

I am all for Soldier safety and glad we are making some improvements and innovation in that space. I do have to ask, why we also aren’t doing the simple and obvious stuff first. Where are the fleet wide installations of backup cameras and airbags in all tactical vehicles. We just had how many Soldiers die in training vehicle accidents and we all have to train to wear seatbelts, but not a penny toward the two most obvious things to improve Soldier safety for the long term.

Even the most recent tactical vehicle in the Army, the JLTV, would never pass even a low speed IIHS vehicle crash test. Blame fro accidents is instead placed squarely on the Soldier, Drivers, NCOs and Leaders and no one looks at the 1970s era death traps, with no visibility, no cameras, no airbags and unpadded steel edges everywhere that the Army still uses.

I would love to see every US Army vehicle crash tested and those results and video made public.