Watertown WI, May 20th, 2022– The Griffin Taper Mount system has been satisfying customers for over a decade with it’s simplistic, robust, and affordable mounting system. A QD system however, offering an active retention system is often times demanded by government customers. A quality QD system should be accurate, robust, reliable, require minimal training, and be free of wear prone metal on metal teeth or ratchets, thereby guaranteeing a longer trouble free service life with minimal maintenance needed. Griffin’s DUAL-LOK™ QD mounting system was designed around these objectives.

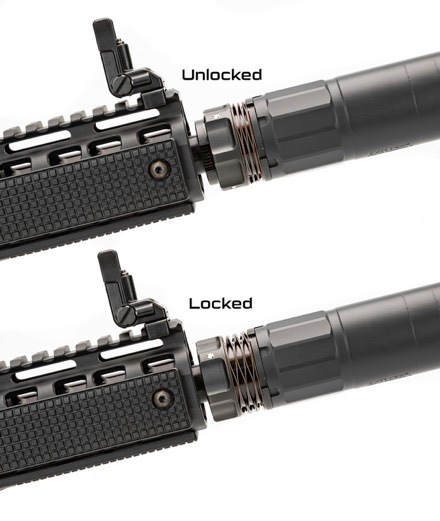

What makes this mounting system unique? It is a combination of desirable mechanical features and performance characteristics in a lightweight, yet compact system. DUAL-LOK™ has great potential for widespread product application. A precision taper interface (one locking feature) between the mount and the device ensures accuracy. An ACME thread, provides speed and ease of attachment. A robust 17-7 Wave spring (718 Inconel on DUAL-LOK™ suppressors) provides a reliable and positive heat resistant spring action to the redundant locking collar (second locking feature). The locking collar is semi permanently installed to the mount via factory pressed splined taper pins. Since the mount has no wear prone metal on metal sliding actions like many other mounts, there is no need for the operator to disassemble the system. This locking ring includes three anti-rotation teeth which ensure the suppressor will not come off inadvertently. The muzzle device integrates 60 machined anti-rotation splines which is doubled by the mount’s two locking positions, hence the double entendre DUAL-LOK™. How is this achieved? The mounts’ two locking positions are machined out of phase of one another by 3 degrees which provides the system with 120 different locations to lock and ensures that when the suppressor is firmly screwed onto the taper a locking spline will be at an ideal location to ensure a rigid and locked suppressor. When the suppressor is firmly attached, only one of the two lock positions will work allowing the spring to push the locking collar rearward over the splines. Every time the operator attaches the suppressor they will articulate the collar to this same locking position.

Substantial efforts are taken in the manufacturing and inspection of the DUAL-LOK™ products to ensure Griffin customers are outfitted with some of the best QD mounting systems in the world.

“I have been studying and designing silencers most of my life, and I am very proud our team for it’s diligence to provide a world class QD mounting system to the market second to none. I spent years, many sleepless nights, dreaming up a system that would check all the boxes and be truly great. We were able to do that. It was a very fun project for me and I am excited to be integrating the DUAL-LOK™ system in several interesting suppressors over the next few years. I have confidence that demanding customers will be well satisfied by this invention.”

– Austin Green, Founder and Engineer

The DUAL-LOK™ system is machined in Griffin’s Watertown Wisconsin facility by freedom loving Americans.

Key points :

• Utility patent pending

• Wear free mounting system, requires no consumable parts

• Taper lock interface ensures security and accuracy

• ACME thread provides speed of attachment

• Locking ring incorporates 3 anti-rotation teeth to eliminate inadvertent loosening

• 120 effective positions ensure a rock-solid suppressor mount and provide extremely low POI shift

• 17-4 stainless steel

• Robust wave spring

• ¾” wrench flats on muzzle devices

• Nitrided black for increased surface hardness, corrosion, and wear resistance

Products Supported :

• 1.375×24 (HUB) DUAL-LOK™ stand-alone mounting system

• DUAL-LOK™ Minimalist muzzle brake

• DUAL-LOK™ Minimalist flash hider

• DUAL-LOK™ 2.25” Stealth Flash Hider

• DUAL-LOK™ Tactical Compensator

• DUAL-LOK™ Titanium Minimalist Brake (6AL4V)

• Suppressors with Integrated DUAL-LOK™ mounts coming soon.

Thread pitches supported:

• 1/2×28 (.22cal & 9mm)

• 5/8×24 (.30cal & .45cal)

• 14x1mm LH (.30cal)

• 18x1mm (.30cal & .338cal)

• 3/4×24 (.30cal & .338cal)

To find out more on Griffin Armament’s entire product line, please visit their website at www.GriffinArmament.com.

So these muzzle devices are backward compatible with existing taper mount devices?