By Aeriel Storey

Army engineers use inkjet printers to replicate explosives samples for testing, training

ABERDEEN PROVING GROUND, Md. — An unlikely fusion of ink, ingenuity and integrated teamwork is applying an existing technology to the challenge of sampling and detecting explosives.

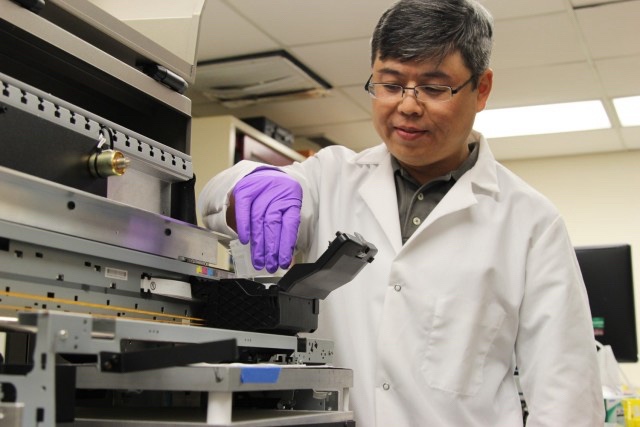

At the U.S. Army Combat Capabilities Development Command Chemical Biological Center, a team of engineers have adapted inkjet printing technology to deposit trace amounts of explosive materials onto surfaces that can be used to test sampling and detection methods.

Since 2010, DEVCOM CBC’s electronics engineers, Raphael Moon and Norman Green, have been working on developing the unique capability by using a commercial off-the-shelf printer that deposits explosive materials on a multitude of surfaces accurately, evenly, and reproducibly.

Their idea to replace the printer’s original ink with explosive materials came from an earlier program that required the use of commercial inkjet printers to replicate detonation patterns. To bring that concept into fruition, a multidisciplinary team consisting of Kevin Hung, Erik Roese, Ashish Tripathi, Erik Emmons and Dr. Jason Guicheteau was established.

“We had to test for about a year before we felt very comfortable trying to print explosives and chemicals correctly,” Moon said of the development process. “The idea of replacing the material in an ink cartridge is simple, but the properties of the chemicals need to be considered for it to work. The ink must have the right viscosity, surface tension and a suitable solvent that maintains the consistency of the ink throughout the printing process that does not damage the printer.”

Precision and accuracy have always been at the forefront of the development process for the system to produce reliable results, allowing for control and accuracy within a microgram. To achieve these results, the team created and tested various ink solutions and engineering options. “We’re really lucky because we’re in an organization where multiple disciplines are all in one building,” said Hung, a software engineer at DEVCOM CBC. “We were able to leverage everybody’s knowledge and experience to contribute to the inkjet project. It was really a team effort.”

Since its inception, the program has demonstrated that the inkjet printer can duplicate samples with high precision, accuracy, scalability, and flexibility for a wide array of various use cases.

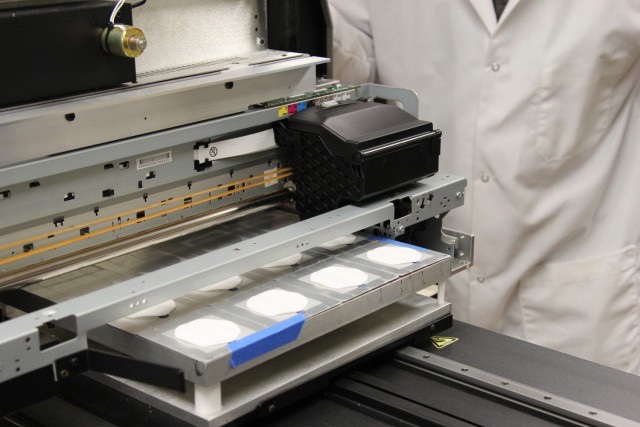

One program that the inkjet printer has been applied to includes the NATO Research Task Group. The program uses trace amounts of explosives to create test and evaluation standards. The program has allowed the team to display the inkjet printer’s ability to print on realistic substrates that would accurately reflect trace detection of explosives in the field.

“We are printing on substrates that replicate materials normally found among debris from detonated devices including car parts, pieces of walls, ceilings, and floors,” said Roese, CBC’s electrical engineer on the project. To print such precise solutions onto objects that vary in size, shape, and curvature is groundbreaking for modern-day printing, and creates a pathway for future developments of systems alike.

At DEVCOM CBC, a team of engineers have adapted inkjet printing technology to deposit trace amounts of explosive materials onto surfaces that can be used to test sampling and detection methods.

These breakthroughs are integral for experimentation and have proved to be applicable in the field. Most recently, the team has been successful in assisting the military on training their working dogs to detect explosives by printing small amounts on sample coupons, as opposed to using traditional bulk quantities. The coupons were buried to simulate sub-surface explosives detection. The test received positive feedback from Soldiers testing in the field and opened more avenues for which the printer could be applied.

The highly customizable system can be used for various projects, requiring in-depth involvement from the inkjet printing team to assist on the specific needs and requirements of the project. “We have developed this system to be accurate and reproducible, so if there are certain parameters that a user needs, we can replicate those requirements for them,” said Hung. “We can also create new inks to mimic instances that users would see in the field.”

The idea has even expanded to include an additional printer, called a nano-plotter, that can be used for smaller, more precise material applications. The team is continuing to pursue projects they can support that allow them to push the boundaries and capabilities of the inkjet printers.