The Malfunction

About a month ago, a Soldier at Fort Knox, Kentucky made a cell phone video showing him attempting to fire his charged Product Improvement Program M4A1 while the selector lever was set halfway between the Semi and Auto detent positions. Naturally, the weapon didn’t fire.

When he rotated the selector lever completely into the detent Auto position, the weapon discharged. The process has been repeated with a weapon from a different manufacturer, but going from Safe to Semi.

As I’m sure you know, it’s not supposed to work that way. Consequently, the Army’s Tank and Automotive Command, responsible for small arms maintenance, issued two separate Safety of Use Messages (18-004 & 18-005), in conjunction with PEO Soldier’s Program Manager for Soldier Weapons to address the issue.

Interestingly, the SOUM directs Soldiers to not attempt to replicate this malfunction during live fire. Of course, they’re going to. It wouldn’t have been discovered if someone hadn’t been messing around in the first place.

Fortunately, no one was injured or killed due to this malfunction. It’s just Joe, doing what Joe does. Except now, Joe videos it.

History

The design for the M16 family of small arms is over 60 years old and the weapon itself has been issued to the US military for well over half-a-century.

In all of that time, we’ve never seen a documented case of this malfunction. Personally, I never considered that a Soldier would fail to rotate the selector lever to a functional, positive detent position. Until someone did it.

The Cause

The malfunction isn’t detected via the standard function check. However, weapons which have the issue will still will work just as they always have, so long as they are used properly. It is also important to note that this issue is not manufacturer specific, having been exhibited in both Colt and FN guns. It may also affect weapons of the other services, so they should heed the SUOMs as well.

When I first heard about it, I immediately suspected out of spec parts. Considering the Army’s efforts to upgrade its M4 and M16 fleets to the M4A1 standard, it’s plausible that they got ahold of some triggers, disconnectors, sears or selector levers that were not manufactured to tolerances called for in the Technical Data Package.

According to Army sources, upon inspection, some of the new ambidextrous selector levers have been manufactured at the edge of the spec. When combined with other parts in the same situation, tolerance stacking has combined to cause the issue. No one specific culprit is to blame.

Apparently, the Army determined that about 10% of the weapons they have inspected possess this defect. I’ve been unable to recreate the phenomenon on any of the weapons (both commercial and govt contract) I’ve had access to over the past few weeks. Still, 10% of issue weapons is an issue which must be dealt with.

TACOM SUOM #18-005 contains a more detailed function check to determine if the weapon will malfunction. Units should perform this check on all M4/16s. It is important to note, even if the issue is present, the weapon is safe to use, so long as it is used properly.

The Fix

The Army is taking additional measures to Using the full range of DOTMLPF analysis the Army considered different ways to mitigate the issue.

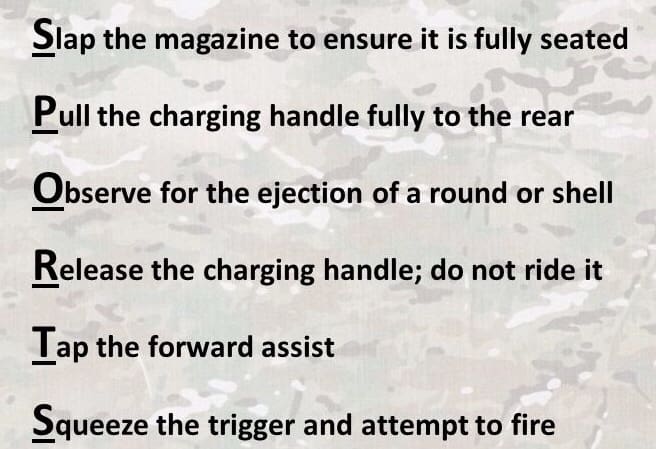

C-SPORTS

One, was to change the Army’s long held immediate action drill from the M4/16, called SPORTS.

Civilians have simplified the procedure to Tap-Rack-Bang, for tap the magazine to ensure it is fully seated, rack the slide to extract the round which didn’t fire and load a new round and bang to fire the weapon.

Due to these misfire, the Army has added a C to the beginning for Check as in check to make sure the weapon is on Semi or Auto.

An Updated Selector Lever

Additionally, the Army has initiated a change to the TDP for the selector lever which adds a chamfer to the face which will force the lever to snap into a fixed detent position rather than remain floating between functional detent positions.

This new version of the ambidextrous selector lever will have the same NSN and units will be authorized to swap out current selector levers for the new one, regardless of whether the malfunction is present.

Although some have called for a hands-on inspection of all of the Army’s M4/16 fleet of almost 1,000,000 weapons by a TACOM team, unit level armorers are more than capable of conduction the function checks and installing the new selector levers. There’s no reason to expend valuable resources on a TACOM inspection team.

Do I dare ask who manufactured the out of spec parts?

Either way, I’m glad they moved on this relatively quick.

sounds like the parts were all in spec – just at the ends of the tolerance bands – so the real blame should be placed on design. tolerance stackups can be a b***h

I can’t remember what company won a contract to make them, but it was some small business place.

“According to Army sources, upon inspection, some of the new ambidextrous selector levers have been manufactured at the edge of the spec”

I’m very interested in knowing who manufactured the parts at the edge of the spec.

Not sure this is the case here, but to cut costs it is common for manufacturers to purposely build parts at the edge of specs. In some cases they do it so there is slightly less machining. In other cases its so that they waste less material (order material on the thin end of the tolerance so they pay for less material).

That’s not how it works. Making something like a full auto safety there’s no cutting costs or saving money by being on one side or another of the “spec”. We make thousands of them, the material cut in the tolerance isnt saving or costing anymore or less. Further I’m curious if these measured out all within the acceptable tolerance of the “spec”. There could be tolerance stacking between all the different parts or even cuts on receivers that led to this but that’s just a guess on my part.

I thought the Army had gotten away from SPORTS as the immediate action drill and went with tap, rack, bang when they came out with TC 3-22.9.

Safety Messages and Alerts Web page (Safety First) has many resources such as Safety of Use Messages (SOUMs), Ground Precautionary Messages (GPMs), Maintenance Advisory Messages (MAMs), and Field Alert messages.

…SOUM not SUOM…

I’m tracking Anderson Arms was the manufacturer for our M4 parts.

I doubt that, unless you can provide the packaging with the CAGE codes on it.

The selectors were awarded to OG Technologies Inc out of New York and Manufacturing Support Industries out of Maryland. The design is the Colt (Canada?)-designed version that was made by Schmid Tool for them but the M4A1 PIP included the TDP for the selector (prints, material, treatment) for bidding.

OG and MSI both make quality products. I wonder if this is a case (like the early B5 contract SOPMODs) where the dimensions were wrong on the prints? A fraction of an inch off and you’ve got problems.

Anyone got a link to the video?