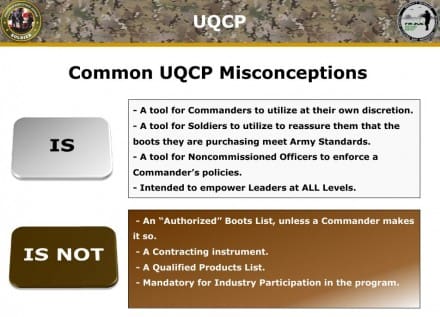

We’ve mentioned that the new Army program called Uniform Quality Control Program (UQCP) would be implemented during the transition to Coyote boots this Summer. Last week, the Army hosted an industry day to explain the program to boot manufacturers and field questions. Authorized by Army Regulation 670-1 dated 2 February 2012, UQCP is meant to certify optional purchase combat boots. Essentially, the Army wants to test commercially available boots because they want to ensure that Soldiers are getting quality boots. All boots submitted for evaluation with have to meet the Optional Combat Boot Product Description (PD) which spells out how they must be made. Specifically, this program will help guide AAFES buyers as they decide which boots to sell at Clothing Sales, but it may also be of use to private military outfitters when selling boots off post. Additionally, small unit leaders may choose to leverage the program to determine if their Soldiers are wearing built-to-spec boots.

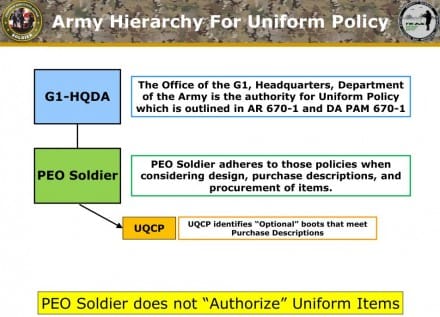

There is a lot of uncertainty over how this program will be implemented. So, up front, it’s important to understand, this isn’t some plot from PEO Soldier to tell you what you can and can’t wear. PEO Soldier does not “authorize” uniform items. Rather, such authorizations stem from Army Regulations. PEO Soldier’s role is simply to manage the program due to their expertise with military footwear.

This slide from PEO Soldier is very important. It shows the intent of the program and while it was envisioned for all of the right reasons, it will assuredly be used as an exclusionary tool by some leaders simply because it is there. As it currently stands, UQCP is very limited, only applying to Berry Compliant boots that fit into the same category as issue Combat Boots. It does not apply to foreign made boots or footwear in a wide variety of specialty categories. Unfortunately, if improperly applied by leaders, there is a good chance that Soldiers in some organizations will not be allowed to wear any of those alternative boot options.

Here are a few facts for you:

-UQCP does NOT apply to existing Desert Tan boots that you wear with UCP. Those boots will most likely be authorized until 2018.

-UQCP does NOT apply to foreign made, NON-Berry compliant boots.

-UQCP currently does NOT apply to these additional categories of boots: Waterproof Boots; Insulated and Cold Weather Boots; Flame Resistant Boots; Safety Toe Boots; Puncture Resistant Sole Boots (Jungle); and Anti-Microbial Lined Boots. Additional categories may be added in the future.

-The initial run is open 2 March 2015 thru 1 May 2015. They don’t plan to open up new submissions again until 1 September, 2015.

-All manufacturer certs for boots submitted by the deadline will be announced at the same time so as to not give one company advantage over another.

-The period of certification will not exceed three years.

-The program is new; expect headaches.

To me, the marking of the UQCP compliant boots is the weakest link in the program. There is no plan to mark or tag approved boots identifying them as UQCP approved. This puts the boot industry at somewhat of a disadvantage because there are going to be boots out there that ‘look’ right but aren’t. Instead, The Army has informed industry:

“End items must include an internal label containing the manufacturer’s product number for the item.” Therefore, product numbers will be required on the internal tag of

all UQCP certified boots. Those product numbers will be listed on the PEO Soldier website in order to allow Soldiers and AAFES buyers to verify the certification of those boots.

Now, I know there are going to be some small unit leaders out there that will have Soldiers take their boots off so that they can compare this number with the ones on the website (which, based on all previous experience with other commodities, will not be kept current). You already know who they are. These are the same folks who stare at your junk, the whole time, when conducting urinalysis.

For many Soldiers, narrow use of the UQCP list will assuredly limit wear of commercially produced boots which many prefer due to alternative fit, materials and styles. For several years, all issue boots have been manufactured on a standard last. The benefit of this situation is that boots will fit the same regardless of manufacturer. The downside is that, for some at least, no issue boot will fit properly due to the common last.

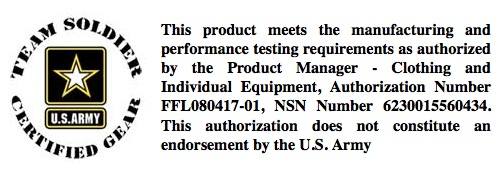

Something similar to UQCP has been attempted, and abandoned, in the past. Way back in 2008, PEO Soldier came up with this great idea called ‘Team Soldier Certified Gear‘ that would have had industry paying the Army to ‘certify’ Soldier Systems items like gloves, eyepro and flashlights. They would then pay the Army a royalty to claim that the item was certified. Sounded like an awesome idea at the time; didn’t last.

In the end, all UQCP does, is provide verification that Berry Compliant, commercially produced Combat Boots meet Army Standards. That’s all. Most of those companies already manufacture contract footwear so they know how to do it and their contract boots are already subjected to these standards. What’s more, UQCP doesn’t cover many of the types of boots that Soldiers will wear (foreign made and specialty) like the mountain boots above which, while issued, are also available commercially. Instead, industry will jump through hoops to satisfy yet even more bureaucracy, that won’t do much for the Soldier, in the long run.

So what boots are those in the image?

If you read the story you’d know that they were issue mountain boots.

Sorry, what I meant to say is who is the manufacturer of those mountain boots, as it says its issued but is also sold commercially.

The ones pictured are by Bates.

Thank you..

bellville actually

All this has shown me is that the Government is a bloated mess to the point of endangering people’s lives just to satisfy some bureaucrat’s need for power.

How freakin’ sad.

Calm down Sparky, you’ll still be able to wear your sneaker-boots while playing Call of Duty.

They release this….before they even release the definitive timeline for the uniform the boots will go with? Nevertheless I thank SSD for their in-depth coverage of all this.

They had to announce this in order to get industry to participate.

*By they, I mean the Army.

Thanks SSD. It’s always good to know what and how stuff works behind the scenes.

SSD have they indicated that there will be any other significant changes to the boots? I mean they always picture the Mountain Combat Boots which are 6in tall. Are they planning on going with a 6″ boot or stick with an 8″?

8-10″

Good, I don’t know why but I like the 8″ boots better.

I think I’m more excited that they used OCP on the background of the PPT!

No, that looks like OCP to me. They’re switching to OCP remember? OCP is out and OCP is in now!

So, if I am reading correctly (admittedly a rare achievement) “Quality” within the world of UQCP simply means it was tested to see that the item meets the 670-1 specs for construction and appearance. This has nothing to do with the common usage of “quality,” as you and I would understand it. It doesn’t sound to me like this will have any bearing on the questions “will it fall apart,” or “will it make me a foot casualty.”

Correct.

This here is Pulitzer-caliber reporting:

“Now, I know there are going to be some small unit leaders out there that will have Soldiers take their boots off so that they can compare this number with the ones on the website (which, based on all previous experience with other commodities, will not be kept current). You already know who they are. These are the same folks who stare at your junk, the whole time, when conducting urinalysis. “

I just call em like I see em.