Cologne, NJ, October 15, 2013 – Global textile supplier Absecon Industries announced today that it is now providing custom design support for its customers to help develop profitable turn-key product solutions that can be brought to market quickly utilizing Absecon’s’ GRID-HERCULES engineered material. Customer benefits include access to innovative designs, rapid product development, and next-generation materials. Precluding the need for manufacturers to hire their own full-time design team or purchase costly 2D/3D CAD software, workstations, design prototype equipment, and laser cutters which can exceed one-hundred thousand dollars.

Customer demand for the GRID-HERCULES material combined with persistent appeals for technical assistance in deploying this new technology inspired Absecon to further assist customers by making available in-house design and product development team for assistance. Initially only for prototypes and trade show samples, but it became overwhelmingly clear that Absecon customers preferred full-time turn-key product development support.

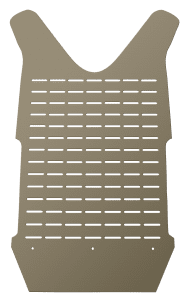

Therefore, beginning January 2014, Absecon Industries will offer bulk laser-cutting, and CAD design services for GRID-HERCULES customers only. Body armor, outdoor equipment, and back-pack designers wishing to employ this new technology, but do not have in-house laser-cutting capabilities, will soon be able to securely upload CAD files to the GRIDHERCULES.COM website for laser cutting and prompt delivery. Likewise, for customers who do not have product designers and product development engineers available, Absecon design engineers can rapidly and cost effectively take a product from a concept sketch to a technical data package. Available services will include 2D/3D pre-production/concept CAD models, drawing flats, pattern creation, laser cutting, collaboration with your staff to build prototypes and capacity to have the initial prototypes built by the Absecon team.

“GRID-HERCULES engineered material represents the cutting edge of textile and polymer technology” said Randolph Taylor, CEO and President of Absecon Industries, “and this service will help guide GRID-HERCULES customers through the complex design and manufacturing process that would otherwise keep them from purchasing our laser-cut engineered material. This new service from Absecon will allow more military and more law enforcement personnel worldwide to access this new technology much sooner.”

For more information on how to become a GRID-HERCULES engineered material customer, contact:

Rusty Burton

Director of Business Development & Sales

Absecon Industries, Ballistics Division

Phone: 865-202-4642

Email: rburton@absecon.com