Oregon-based USIA (Under Sea Industrial Apparel) and Virginia-based NanoSonic, Inc have combined their manufacturing and technical expertise to transition NanoSonic’s HybridSil FR technology to dry and wet suit ensembles. Developed under a Small Business Innovative Research grant, the diver armor equipped dry and wet suits will be initially available for the military and public safety sectors, and as many next-generation defense technologies have in the past, may transition to the commercial and recreational diving communities.

Oregon-based USIA (Under Sea Industrial Apparel) and Virginia-based NanoSonic, Inc have combined their manufacturing and technical expertise to transition NanoSonic’s HybridSil FR technology to dry and wet suit ensembles. Developed under a Small Business Innovative Research grant, the diver armor equipped dry and wet suits will be initially available for the military and public safety sectors, and as many next-generation defense technologies have in the past, may transition to the commercial and recreational diving communities.

Leveraging NanoSonic’s R&D 100 award winning HybridSil core technology, virtually any fabric may be infused with a molecularly engineered ceramic nanocomposite for drastic gains in environmental durability and chemical resistance with negligible influence on drape and weight. The primary focus for the first generation of dry and wet suit materials has been enhanced laceration, abrasion and puncture protection over current state-of-the-art materials. These fabrics are 15 times stronger than steel and 40% stronger than aramid fibers such as Kevlar and Nomex.

USIA was chosen by Nanosonic as its exclusive Phase III transition partner due to its extensive experience within the military and recreational diving business and immediate synergy with NanoSonic’s HybridSil technical team.

USIA is led by its founder Kim Johns, who has more than 28 years of experience in the military and public diving industries. “The bottom line benefit is a novel material that creates real dive armor,” said Johns. “For over 30 years we have all been making drysuits and wetsuits from the same types of materials – usually laminated materials (tri-lams and bi-lams), which can delaminate and separate under stress.” This technology infuses a coating on the material that changes the chemical composition and creates a innovative composite material – in this case, drysuit exposure protection. These new nanocomposite materials are fantastic. They are highly flexible and lightweight, yet extremely durable, tough and chemically resistant.

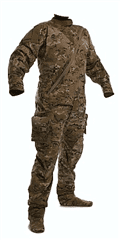

“In the short term, this new material will replace overlays for high wear areas in drysuits and wetsuit,” Johns stated. “High-use places like knees, elbows and shoulders will get an overlay that will add an extremely lightweight, pliable, yet tough layer to protect the diver. In the long term, we will be making entire suits out of these materials.”

According to Vince Baranauskas, PhD, Vice President of Polymer Science and Engineering at NanoSonic, HybridSil Dive Armor crosslinks molecules across the matrix, fiber and host ceramic particle interfaces to create an innovative product that merges the best qualities of any fabric with otherwise unobtainable performance enhancements. Imagine a light fabric that feels like paper but is 10 times stronger than any other product available. Vince Baranauskas received his Ph.D. in Macromolecular Science and Engineering at Virginia Tech, with a focus on the synthesis and characterization of siloxane functional block, random, and graft copolymers for use as durable oxidative barriers for metallic nanoparticles. Baranauskas co-invented the core technology, HybridSil, an advanced copolymer nanocomposite technology that is currently under evaluation on multiple military and commercial platforms.