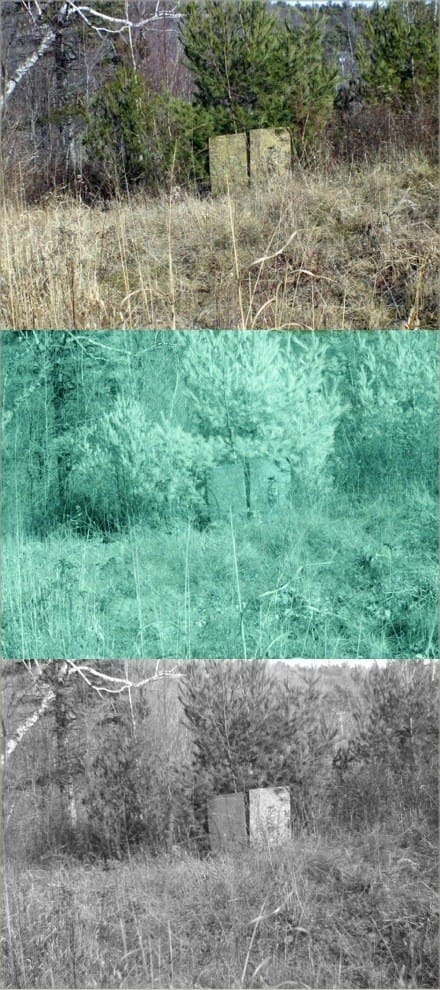

UVR Defense Tech, Ltd. has sold licenses to Essex Flameproofing, Ltd. (Euroflam) to apply UVR’s technologies – UVRC and nanoTarge – within the U.K. UVRC(patented) is a camouflage for the ultraviolet spectrum that may be applied to conventional camouflage without altering the visible and near-Infrared properties of the fabric. nanoTarge (patent pending) both strengthens and protects technical and ballistic fabrics, providing as much as a 2.5 fold increase in tear strength. See http://nanotarge.com for details.

“We are pleased to have Euroflam presenting our technology to the U.K..As government and military budgets tighten, Euroflam will be able to offer a low-cost method of strengthening, and providing longevity to, all their technical textiles. This is significant to all sectors. For example, a firefighter’s turnout gear is made of a heat-resistant fabric with a short lifespan due to ultraviolet degradation. With nanoTarge, Euroflam can increase the tear strength of the fabric, as well as prevent UV degradation, resulting in significant cost savings for financially-strapped municipalities” stated Reed F. Curry, President of UVR Defense Tech, Ltd.

Alan Eyers, the Operations Director of Essex Flameproofing Ltd. / Euroflam noted “We are very pleased to add the unique treatments, developed by UVR Defense Tech, Ltd., for the coating of Fabrics & Textiles used by the Military, Emergency Services, & Law Enforcement Agencies. These give added protection to a wide range of textiles, offering new permanent UV signature management solutions for uniforms, tenting, equipment covers, and also reduces the effect of degradation by direct Sunlight UV rays on these types of fabrics. The License Agreement affords us the ability to treat such textiles for UK base suppliers and manufacturers, as they sit very nicely alongside, and are compatible with, the other advanced Flame Retardant and Protective treatments we offer.”