NAVSUP Weapon Systems Support, Mechanicsburg, PA has issued a Request for Information to industry for Suppressors compatible with the M2A1 .50 Machine Gun.

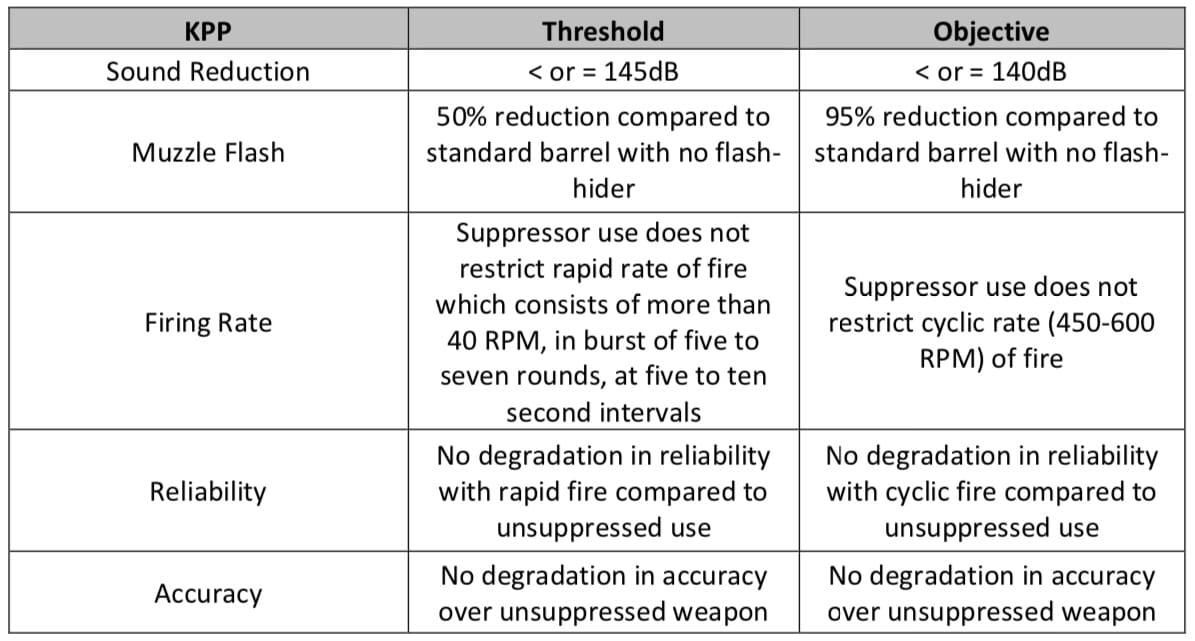

In addition to being resistant to a maritime environment and having no impact in barrel life, the Navy desires these capabilities as well:

This shall be interesting. I’m legitimately curious as to how each company that enters this, will combine all the engineering, technology, manufacturing, and design to withstand all the force of a .50 cal.

In the long run, I hope the civilian market benefits from this.

They want a COTS item.

I’m not aware of a COTS Fiddy can that can withstand sustained F/A fire.

And, oddly enough, .50 BMG is the only suppressed caliber that i have shot that the recoil is actually increased. Enhanced wear and tear on parts is to be expected.

This will be interesting.

Heat

Bulk

Sights

Barrel change

Its going to be complex. Titanium is almost mandatory, I suspect the suppressor to be as long as the barrel. Is this for ship board use or special opps?

Shipboard

Have a look at a M1921

It has a reciprocating barrel within a air/water tight jacket.

This holds promise for a ‘reflex’ style suppressor that does not add considerably to the length of the barrel or require the reduction of barrel mass to compensate for the mass of an attached suppressor.

In addition, the large internal volume of a M1921 sized suppressor should work in it’s favour.

Total bastard to clean though.

Further thinking: it would work…but I can’t accurately calculate how much extension beyond the muzzle bearing you would need to be effective.

You could even use existing M2HB barrels if you made the outside of the muzzle uniform, maybe hard chromed it.

Existing M3 would be an easier conversion but lower barrel mass means sustained fire limitations.

300C maraging alloy would be a good material candidate (Like in the Energetic Armament Vox series), as it’s stronger at 1000 degrees C than anything else at room temperature, allowing extreme strength with minimal material, allowing lighter weight and higher operating temperatures. It’s used in rocket casings and is ITAR controlled.

and DeltaP for the win..

Agreed. With the rocket nozzle nickel alloy.

5-7 rounds every 5-10 seconds lol. I hope they build it stronger than that. I suspect it’s going to see a bit higher rate of fire than that. Just sayin.