In early August we casually mentioned a new proprietary 6.8 magazine coming from Magpul for an LWRC International Six8 project. Called the Ultra Compact Individual Weapon or UCIW, we can now show you a little bit about that gun.

Currently, they have contracts for 6,000 of the new guns and LWRC’s Darren Mellors shared some background of the project on their forums, “All forgings (upper and lower) are coined. Meaning they are struck once (as all AR’s are) to make the forging, then heat treated, then coined which is to take the cold (unheated but heat treated and aged forging) and strike it again in the forging die. This costs more than twice as much to do, but it dimensionally corrects any wandering that may have occurred in heat treating, and creates such a beautiful exterior, they look like they were created by the gods. The argument for billet or forging is over. The best strength characteristics of a forging, with dimensional accuracy of a billet receiver, and beauty that surpasses either.”

Here you can see the ambi controls of the UCIW.

And the reverse of a test gun.

As we understand it, they are also working with a new cartridge in 6.8 (SPCII) manufactured by ATK. Here, you can see an early test gun and ammo boxes.

Based on this ballistics demonstration, looks like this new cartridge and carbine combo is going to do quite well. 0.5 inch AR 550 Brinell Armor plate. Shot an 8.5″ 6.8mm UCIW and SSA Armor Piercing ammunition at 100m. Full penetration.

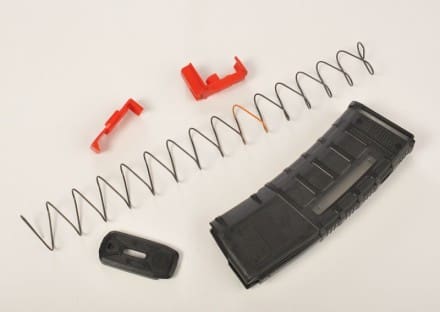

And finally, here is that Magpul magazine we alluded to. As you can see it incorporates much of the M3 technology we discussed.

Notice that we’ve mentioned that this magazine is proprietary to LWRCI. The reason is that the magwell for this Six8 lower is a little different than a standard 5.56 lower. They aren’t ready to release these new dimensions to industry just yet.

Unfortunately, it looks like you won’t be able to just go out and purchase a new upper and slap it on your existing gun. Not only is the lower dimensionally different in a couple of ways but the upper and lower interface differently than standard ARs.

According to LWRCI’s Jesse Gomez some standard AR parts will fit the UCIW.

Parts which will interchange between the AR15/M4 platform and the Six8 architecture:

Upper:

Barrel Extensions and barrel assemblies, Barrel Nut, Forward Assist, E-Port Door Assembly, Charging Handle, Cam Pin, Firing Pin and the Bore C.L. to Gas-Tube/Op Rod C.L. dimension remain unmodified. Most free float hand-guards can be used with no mods.

Please note: A standard Bolt and Carrier will work without modification, but due to tolerances and tolerance stacking rubbing between the outside of the mag feed lips and carrier may occur. Hand cycling of the weapon a few times with the mag insert will easily correct this. We opted to enhance our carrier for additional clearance of the feed lips. In regards to the bolt we included the very same up-grades we developed for the M4 Product Improvement Program (PIP) into our 6.8 ACB (Now the Mk II ACB) for greater extractor to shell interaction for increased performance. Imagine an AK74 extractor in an AR. All other features of the ACB carry over.

Lower:

All lower parts interchange with the exception of the magazine catch assembly and the bolt catch. A standard both catch will work but you will need to remove the ambi bolt catch components. Everything else is a direct drop-in.

For the class III folks, the Six8 lowers are milled to low shelf configuration.

For those of you who are interested, we understand that this new gun will be available late this year, in all barrel lengths, and hopefully in an IC configuration. All photos originated in the forums section of .www.lwrci.com

Already on a wait list for one of these.

I hate to say this, but it doesn’t take a lot of critical thinking to call BS on the LWRC’s “coining” business.

I’m familiar with the process. It is often used in aerospace or medical applications where volume and/or weight constraints call for maximum strength parts, and the market’s margins justify the added cost.

I don’t see LWRC making any substantial dimensional changes to the upper or lower that would warrant using the process. Unless you are shaving ounces of weight off the components by making the walls thinner or something, the only reason you use this process is to… say you use the process.

Personally, I’ve never seen a bog standard upper or lower break. So why all the bother about how great your forging/machining/nano-moleculuar assembly process is for making these pretty standard and well proven components?

Indeed “created by the god’s” is strong language. The virtues of beautiful exterior on an M4 are lost on me.

Can i just get the stock? will they be sold separately?

Anyone have word on who is building their flash hider? Are they doing it? Looks like a 4-prong but not sure. Best of luck to this VMI-linked company!

Guess this won’t be available to civilians, according to Recoil Magazine policy. Obviously has no “sporting purpose”! couldn”t resist!

Some corrections to what is in this article. The plate was shot with SSA Armor piercing, not the fusion bullet ATK has developed for the platform.

The receiver coining is done not for beauty (although it is really nice), does cost twice as much, but was done to ensure a higher level of dimensional accuracy. We did not invent it, as said by the poster is called on many aerospace forgings for increased dimensional accuracy. We are the first to use it in the AR industry. Most of the external dimensions on a forging are irrelevant, however they are relevant when you put them into a machining fixture.

Having the tighter forging tolerance really reduces receiver rejections and reliance on touch probes to set offsets. Most rejections with an AR lower relate to the ejection port door pin holes. There is a very small margin of error in their location. If off, the ejection port will not close. The other features on the receiver are all co-located off of the front take down pin hole, so not as critical. Just limiting and controlling variables. That’s good right?

The context of my comments were to address the internet debate on what is better, a forging or a billet receiver and that this process puts that to debate to rest.

The magazine well was enlarged to accommodate a proper 6.8 magazine made for the 6.8 cartridge constructed of polymer. Well worth doing. If you have a different opinion it must because you do not shoot 6.8 out of an AR platform. Magazines have been a major stumbling block for 6.8 since the beginning that we and customers have struggled with. Now we nor customers have to struggle with it any longer. Magpul thought is was worth doing. So much so, the investment in tooling was theirs. It is a matter or limiting a variable and controlling it.

The stock will be sold separately, we have two lengths, the one in this picture which requires the shorter buffer tube, buffer and spring, and a standard M4 length.

The flash hider is made here and made specifically for this short barrel.

[QUOTE]The context of my comments were to address the internet debate on what is better, a forging or a billet receiver and that this process puts that to debate to rest.[/QUOTE]

What makes you think coining ends the debate on forging v. billet? In reality, the debate itself is asinine insofar as the AR lower and upper are the least failure prone components of the entire system.

Billet is the appropriate method for manufacturers looking to differentiate a low-volume lower with a non-milspec feature set without the massive tooling investment forging dies would cost. If you are gonna make a boatload of lowers/uppers and the forging cost savings versus the tooling investment pans out… go with the forged net shape.

How does coining pencil out vis-a-vis the reject rate reduction? When you coin, are you simply hitting the net forged part a second time in the same die? Or do you buy a whole new die to do the coining hit?

If it is the latter, I can’t imagine how big the non-coined reject rate would be in order to justify buying a big-ass forging die. If, on the other hand, “Doubling the cost” really means “Pay Skippy the Forger to heat up the billet and hit it again in the forge,” that makes a lot more sense.

Coining allows the forger to correct any wander in the forging tolerances after heat treat and aging and hold a tighter tolerance. We had a forging die made $8000 (big coin according to you) to accommodate the wider upper and lower receiver and ambidextrous controls not found on the AR/M4 lower. We asked for tighter dimensional tolerances on the forging. This would guarantee what WE wanted. I really wanted to ensure people had the correct information here as I sincerely respect this website as it usually cuts out much of the fodder.

Really, we do this every day. The forger does it every day. I appreciate your knowing advice though. I think you must be bored or something.

Darren,

thanks for coming in and updating us.

Eric

Mod, I think I put my email address in wrong. Did not notice until after I pressed the submit button.

How much is the MSRP likely to be and will you plan on offering one in a CA friendly configuration? I’ve been wanting an AR for a while and when/if I ever get or build an AR this one would definitely be on my list of ones to consider if it comes in a CA friendly version.