Despite adoption of polymer magazines by USSOCOM, the Marine Corps, and even the Air Force, the US Army has yet to join them. To make matters worse, the Army has evaluated polymer rifle magazines several times, and seems to have ignored their own results. In fact, the Air Force is said to have based their decision on the last Army test report. Granted, the Army has authorized use of the Magpul GEN M3 PMAG, but unlike the others, they haven’t made it their primary magazine.

While there’s been lots of online conjecture as to why the Army hasn’t adopted a polymer magazine, the true answer may well lie in this slide from a briefing presented by LTC Steve Power, PM Individal Weapons at PEO Soldier’s PM Small Arms, during NDIA’s 2017 Armament Systems Forum, this past May.

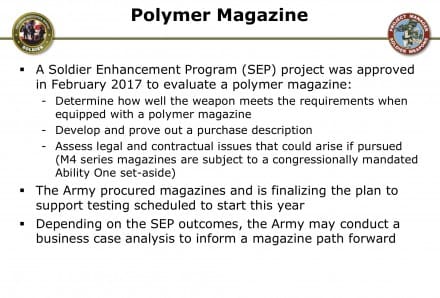

The Army is going to conduct yet another polymer magazine evaluation under the Soldier Enhancement Program. Direct your attention to the sub bullet on the slide below, which states, “Assess legal and contractual issues that could arise of pursued.” Most fail to understand the significance of that statement. Turns out, what’s holding the Army back is something bigger than any of us; procurement set asides.

To begin to understand why it’s so important, you need to know that AbilityOne has a government-only sales website sponsored by three organizations, National Industries for the Blind, SourceAmerica (formerly NISH), and the US AbilityOne Commission, the operating name for The Committee for Purchase From People Who are Blind or Severely Disabled. They are all involved in providing goods to the US Government, based on the Javits-Wagner-O’Day Act or “JWOD Act” authorized under 41 U.S.C. 8501-8506c. These nonprofit agencies manufacture a variety of commodities throughout the United States, and employ people who are blind or have other severe disabilities. It’s a public/private success story.

Not only is the program Congressionally mandated, the AbilityOne Program employs more than 47,000 Americans. As you can imagine, this gives it a lot of clout. Essentially, once a commodity is provided via a directed source, it always will be. That’s why the legal review was mentioned as a factor, perhaps as important as, if not more than, how well the magazines work.

By now, you’ve said to yourself, “Well the other services have transitioned to the PMAG, why can’t the Army?” The answer lies in the numbers. The Army’s buying power is massive when it comes to small arms amd accessories. It buys more than the other three services combined, and that’s even if you add SOCOM into the equation. For the Army to drop a directed source is a very big deal and they will assuredly face Congressional pressure over such a move.

While it’s certainly frustrating to see the Army move so slowly toward the the wholesale adoption of a polymer magazine, we understand that there’s a bit more to it. That’s why we are publishing this information. You need to understand it as well. The Army needs to get its ducks in a row in order to make the business case for transition. But now that all of the cards are on the table regarding what’s at stake, there’s no excuse to keep kicking the can down the road. While performance must trump set asides, the question is, how much does performance need to improve for the Army to upset the rice bowl?

The Army has never come to terms with magazines being disposable items – they want to hang onto all of their old mags until they rust into oblivion.

“Who cares if black followers went out more than a decade ago – that’s what you got from Supply, that’s all you get. And you better keep track of it and turn it in. And don’t give me any of that nonsense about it causing feed failures – that’s because you rest your mag on the ground, or you over-lube your weapon, or something.”

…yet there were several disposable pre-packed magazine programs in the late 1960’s.

In fact, the Australians & Kiwi’s scavenged a lot of perfectly good M193 Ball from the leftovers of one: a resin reinforced fiber affair with a pull pin that released the spring against the round column.

The mags were tossed because some fungus like the resin.

a friend of mine found a 20rd mag from Vietnam when we were in kuwait in 2014.

We deployed to Iraq in ’06 with a footlocker full of 20 round mags. When it was time to return to CONUS, the IG that was inspecting our conexes found them, and couldn’t believe my unit was stupid enough to cart 20 rounders halfway across the planet.

Ahh I remember in 2012 while in the stan a directive coming down banning all of us from using polymer mags and everyone just laughing at it and continuing mission.

Bottom line:

What’s the price difference, Original GI aluminum vs. polymer?

how many does the Army buy each year?

Reliability difference?

Durability difference?

Does anyone know which of the past army, aluminum magazines, or the current enhanced magazine are manufactured by any of the listed Ability-one or related companies?

The current enhanced mag is made by Center Industries Corporation of Wichita KS, they are an AbilutyOne manufacturer.

Thanks.

These magazines are highly reliable. I have fired tens of thousands of rounds without a single stoppage attritued to the magazine (going as far as 1,500 rounds with nothing but 3 drops of oil and a quick wipe of the bolt without further disassembly). They green and gold followers are absolutely fantastic. Saw multiple failures of the PMAG…to include highly embarrassing failures in front of foreign couterparts…unless they fixed this problem I will continue to advise people from using PMAGs with MILSPEC M4A1 rifles when they try to load a 30 round magazine with a round in the chamber…and before the arm chair shooters chime in about their fake Vietnam experience, this has not been a problem with the last two generations of issued magazines.

I know Brownells was making magazines a couple years ago and were using Co-Line to bend the shells. My dad worked there during the time and talked to the management about things, they said it was fun when the military came to inspect the magazines and got to go to the range with them to test them. I don’t think either Brownells or Co-Line are Ability-one certified.

Ahhh! I don’t want my lifesaving equipment made by blind people.

Why not, when your universal camouflage pattern looks like it was chosen by blind people? Not letting it go…

Were phaising that uniform out. I havent worn it in avout a year

What is wrong with Lighthouse for the Blind? They feed us, And they feed us well….and if you are super lucky you get an extra pound cake in your MRE.

Nothing, it’s a joke. I thought it would be funny.

I see that it’s a joke. Blind people are actually extremely good with their hands. In Japan, blind people give massages. That could be for a variety of reasons….

The Enhanced Performance Magazine (1005-01-630-9508) is, as are at least two prior versions (1005-00-921-5004 & 1005-01-561-7200).

You can search their procurement list – http://pl.abilityone.gov/procurement_search/procurement_product_search.aspx

So if that is the case, why doesnt Magpul subcontract with AbilutyOne?

Farm out some licensing and manufacturing to them and then everybody wins.

– Magpul sells a billion more mags

– AbilutyOne employs a whole basket full of new manufacturing people.

– Soldiers get mags than dont suck

– Taxpayers can stop paying for yet another freakin test.

Because some high ranking official is waiting for their share of the cut, who ever gives them the bigger pay check, we adopt that one ;)… not a joke…;)

Do you have evidence to that end?

https://www.youtube.com/watch?v=4f2XbOY9kcg

What does that have to do with the allegation that an official is involved with malfeasance regarding rifle magazine purchasing?

By that reply Eric, do you think the SCAR program test was “fair”?

What’s up with the “I love lamp” comment?

I do “love lamp”! Is that a problem??

What does your love of lamps have to with rifle magazines?

Something something something… industrial base… jobs program…

Source America… yet another example of fraud, waste and abuse. SourceAmerica is the reason why the government is still buying JSLIST suits, even though they dont need them. The Government is still obligated to purchase them, even though we don’t need them, to the tune of 60,000 per year over the next 3 plus years.

You have heard of this place called North Korea, right? Somewhere Joe (and the contractors supporting him) will be changing suits up to 3 times a day for 6 months.

Pretty much. Hopefully they don’t hit us with Bio, because the JSLIST does awesome against those tricky little bugs…

Point is, all JSLST (and successor technologies) purchases are necessary. The fight the CinC seems to be picking demands it.

Gear Guy,

Fedgov not needing a contracted item and wasting tax dollars on it’s procurement, has been going on more than 72 years.

When World War Two ended many brand new aircraft were flown from the factory, directly to a scrap yard. Brand new. Never to used. Just sat in a boneyard waiting to be scrapped.

No matter what anyone thinks, it is what it is and Ability One will play a huge determining role in if the Pmag ever gets adopted.

This is why the Army continues to improve the GI mag, and why Center often makes them.

I can speak from first hand experience in Navy and Marine Corps buying, from new flight gear to office furniture. NIB and NISH, now Abilitiy One TRUMP everything! Yes, all reason, logic, cost analysis, competitive bidding. You want your major purchase approved in less than 10 years, go Ability One! If not you must submit detailed dimensions, intended use and function, materials and after those requirements are approved buy the bureaucracy up the chain it goes for open bidding. Or, you just go though Ability One contracting source and buy what you want.

Example is office furniture. I was directed by a 3 Star USMC to require our building that, his words, was a “shit hole”. We had millions in end of FY dump money to spend and I had two weeks to do it. I tried to buy from a proven contractor I had used while serving in the Navy side. MC purchasing said I could not specify a single contractor. I had to specify number of desks, desktop size, number of drawers per desk, size of drawers, number of chairs, swivel, reclining, etc. WTF? Then Purchasing would review and approve or decline. That wasn’t going to happen in two weeks, especially for a building. General and his Staff Action Officer was getting very impatient with me. “Spend this money, NOW!” Then Purchasing told me if I went NIB/NISH I could go sole source without any hassle. I called the NIB/NISH contractor, she came out, measured the office space, produced a furniture replacement plan and Shazam, it was instantly approved. $500,000 worth, in three days.

Thank you for the explanation. Action One is a pet of Congress. They go for photo ops and get to take credit for all the jobs in their districts even though they had no direct hand in it. Action One by Congrssional direction trumps everything. Frustrating but that is our system.

THANK YOU SSD for digging and publishing the details out.

No doubt the Army screws the pooch all too often but having the logistics behind the current state of affairs is so much better than listening to the wholesale schadenfreude from gear groupies and Army haters.

You continue to prove the old adage, “Amateurs talk about tactics, but professionals study logistics.”

Remember thst time that USSOCOM ordered a magazine reliability study of all six manufacturers of NSN USGI mags and Center Industries performed so poorly that Crane put out a stop use on them and authorized units to circumvent the NSN system to avoid them?

Pepperidge Farms remembers……

Let me guess you hear about that on a YouTube podcast?

I realize that most of the “action” these days is in HOT places.

However, what happens to polymer mags at sub-freezing temperatures?

Certain batches for mags for the Steyr AUG / (F-88) were prone to fracture when dropped (filled) or struck on hard objects when it got a bit frosty.

Polymers. especially “inappropriate” ones, tend to do that.

On the other hand, on hot days, the heat-induced softness of the mag LIPS caused “round spillage”, in the pouches, especially during “vigorous’ exercise.

If your putative polymer mags are glass-fibre reinforced, they will not go “soggy” and may even better withstand the usual abuse.

Aluminium mags suffer more from damage to feed lips, especially when filled and dropped on their heads, by careless troops.

Maybe the correct grade of steel, correctly heat-treated, would be the go.

I dropped a canteen in the mountains while I was in Ranger School in January. I forgot to place it directly next to my body like the RIs said. It shattered. Had that lesson driven home again when I closed the soft top to my Jeep in Colorado in minus degree weather too hard. It cracked. Plastic gets brittle when it gets cold. It gets really cold in North Korea, China, and Russia….

The PMAG is tested to -60F in both feeding performance and drop testing that exceeds any mil test.

I can recall all sorts of equipment that was tested in laboratory conditions that failed to meet operational conditions. Example, the PMAG was dropped tested originally empty….have those drop tests been updated with a full 30 round magazine? I don’t have that concern with the last two generations of issued magazines. They are metallic, they don’t create stoppages because of weak springs, and are lighter than several other options.

Just a quick one: How do the Canadians get on with THEIR polymer mags?

Doesn’t Canada mostly use GI mags?

I am not sure I agree with the endorsement of PMAGs. I have personally witnessed multiple instances of failure to seat when a 30 round magazine is loaded during rapid magazine transition drills when a round is already in the chamber (in other words you get that extra little bit of downward pressure). If you didn’t give the PMAG that deliberate extra effort to seat it would often simply fall out or cause a stoppage. Did they solve this problem? I mean the tiny bit of weight saving was great (ounces equal pounds). However the PMAG circa 2013 was not acceptable. This was an issue even with experienced shooters, and given the fact that the Army caters to the lowest common denominator, this issue could become a serious problem. So are there any recent shooters who have been to Range 37 course or the annual train up prep course that ran PMAGs without any issues? Asking for a friend.

Have you been to Range 37 for any course? I have, I still go there to visit quite a bit.

1. The PMAG is slightly heavier than a GI mag actually

2. If the PMAGs weren’t as good or give them issues , why do they keep buying them.

I don’t care why dumb people buy things. I only care bout what really works. If you are a Range 37 vet, you should remember the HK mag fad that was part of the prevalent pop culture of the day. It was heavier that the standard mag, but the lip of the magazines was highly vulnerable to being bent. Still, “shooters” swore by them because they were HK. PMAGS were offered to teams, because they were funded for a bit…but you don’t see a lot of guys carrying them today do you? Explain that.

Oh, and to directly address your question…if things weren’t as good or give them issues…them why is the M9 still being used when the Glock 19 has proven to be superior? Could it be there are other, more deeply embedded issues to contend with?

RE: M9 vs. Glock, one is stock funded and required to be in the arms room by big army, the other is bought by the unit with discretionary funds. In the last six months, we’ve been over this at least thrice that many times.

Last I knew, Center Industries is the is the primary supplier of the aluminum mags. They are a “sheltered workshop”. No idea if affiliated with the companies mentioned.

How many posts until somebody says that we need to bring back the Garand or M-14? I wish I was joking, but I’m honestly waiting for it at this point.

Paging H20-MAN.

I think that the Ability One job program is an excellent opportunity for all of the disabled people. Hopefully a resolution can be made.

Y’know… I think there is something more to the whole issue than just the “hire the handicapped” set-asides.

Way back when, circa 2003-ish, I had a conversation with a DA technical support type of person, from either TACOM or PEO Soldier (can’t remember which agency it was, but he was a small arms guru), and I asked him why the hell the Army was not adopting the MagPul anti-tilt follower. His reaction? “The Army will never buy anything from MagPul, and will spend millions to avoid doing so…”. I asked why, and about all he’d say was “Are you familiar with the reason why the US Army didn’t buy the Lewis Gun…?”.

You’ll note that MagPul had their anti-tilt mag follower on the market long before the Army decided to “product-improve” the standard magazine, and that they spent millions having Lancer and others develop an Army-sponsored polymer magazine, instead of just doing what everyone else who was actually out in the field suggested: Buy MagPul.

Why this was? Dunno, but you can see an outline here of something very similar to the whole fiasco with camouflage, in that they didn’t want to pay someone like MagPul or Crye for their proprietary intellectual property. MultiCam arguably came out of the Scorpion pattern that the Army paid for, but the improvements implemented were Crye’s own work on their own dime. Just like with MagPul and the improved anti-tilt followers, along with the polymer magazines…

There’s a thread here, one that smacks of an essential moral corruption in the procurement field. They’ve done similar things to folks like Eagle and others with the body armor and nylon gear, over the years–Solicit bids, and then somehow, the Army-ized copies of the proprietary gear wind up being what gets procured, without a dime going back to the original innovator. Look at what they did to Tyr, over that backpack-mounted magazine deal, for another example. The folks at PEO-Soldier sold that deal as something they innovated themselves, expecting the world to believe that they didn’t know about the Tyr Tactical product that predated their own implementation of the idea.

What’s not at all funny about this shit? We’re paying for this crap with our tax dollars, and I have the sneaking suspicion that there’s a factor here where folks in the procurement agencies are padding their resumes and evaluations by what they “invent” on their own by swiping ideas from outsiders, and then not giving them credit.

Not to mention, there’s a certain whiff of sheer incompetence about it all. One of the guys I spoke with about that backpack MG magazine thing was completely (or, so he said…) unaware that Stoner had already been there with the AR-10, back in the 1950s.

Another thing we did? Circa 1969-ish, in Vietnam, we paid Hughes Aerospace (or, whatever the hell name they were doing business under, back then…) millions of dollars to evaluate thermal sights and IR as a means of locating mines and IEDs in Vietnam. There was field testing of a jeep-mounted sight system that I think was derived from what eventually became the thermal imaging system on the M60A3 TTS and the M1 Abrams. During that testing, they determined that the use of that equipment was not effective, and that the idea was probably a dead end–Not enough thermal differentiation between a buried mine and surrounding soil, out in the real world.

Come 1991, some guys tried using that technique with the M1 tank sights, and probably what few M60A3 TTS systems got into Kuwait and the Gulf. From that, someone else had the brilliant idea that maybe we could use thermal imaging to locate mines and IEDs… So, the Army let a contract for millions of dollars with Hughes, again, to test the idea. This time, maybe they can make the excuse that they were thinking there might be a difference that mattered, based on doing it in a desert. Turns out, not so much.

Funny thing, though–I spoke with the engineer who was the project manager for that series of tests during the 1990s, at the behest of my then-boss, and that engineer was shocked and dismayed to learn from me that he was repeating work that Hughes had already done, some twenty years earlier. Both the Army and Hughes had lost institutional memory on the idea, and were re-inventing the wheel. First that the project guys at Hughes knew of that was when some smart-ass Staff Sergeant called them up with a few questions from his boss, and blithely informed them that there was probably a raft of information in their company archives, if they could find it.

The guys at the Engineer School who’d initiated that whole thing, in the nineties? Blithe ignorance, and they hadn’t even checked whether or not the work had already been done. Hell, one of them wasn’t even aware that they’d had thermal or IR back then–He was shocked to learn just how far back that technology went. He genuinely thought he’d come up with a new idea.

Which just goes to illustrate the points I’ve repeatedly made, that the Army is essentially ahistorical and unable to learn from past experience as an institution. Too many people let their personalities and egos get engaged, and whatever it is that MagPul did to piss them off…? Well, it’s still having an effect. I don’t know the ins-and-outs, but I’m pretty sure there’s something there, in the background, and whatever it is, it likely doesn’t reflect well on our institution.

I think that the camo problem was more of having Scorpion developed, but UCP being fielded. Afterward, even though supporting companies is good, why would it make since to pay for Multicam when they had already developed and owned Scorpion? If there was no significant/justifiable operational advantage in Multicam, they made a good decision. UCP blows my mind and will forever. I wish those who made the decision would be clearly singled out and made to testify.

The question is, why the hell didn’t the powers-that-were go with the pattern they’d already paid to have developed once, for the Force XXI project?

Hell, everyone out in the field was expecting the new pattern to be MultiCam, when the announcement was made. When UCP showed up, instead? Yeah, we were all a little shocked and going “WTF…?”. I honestly expected the new pattern to have had some damn basis in real-world testing, or something. Turns out, not so much–It was down to the prejudice of some higher brass.

As well, note the issues with the ACU trouser crotches–Same-same issue can be found in the hot weather uniforms going back to WWII. The original WWII jungle uniforms had problems with the crotches blowing out, the OG-107 initial issue during the Vietnam era had the problem, the initial fielding of the Hot Weather BDU, and the initial versions of the ACU. I mean, seriously…? By this point, there should be a f**king wall hanging up at PEO-Soldier that says something to the effect of “Don’t forget about the crotches on new hot-weather uniforms” in six-foot tall letters. Literally–The first iteration of the ACU had the same damn design and stitching done on them that I remember from the initial HWBDU back in the 1980s. How the hell did they forget that shit?