Dive Knifes

The general maintenance of your dive knife is easy and will not be hard as long as you get into a good habit of always raising the knife and scabbard in fresh water properly.

Post Dive care

After diving, rinse the knife and sheath in fresh water. Wash the scabbard thoroughly to ensure no salty residue is left inside, remove the knife from the sheath and operate any moving parts while soaking. This helps remove sand and other debris that may have gotten inside. If not done properly when you put the knife back the remaining salt will cause the blade to rust. If the knife can be disassembled (usually by taking the handle off), take it apart and rinse the individual pieces in fresh water after every couple of dives or if you plan to store for a long time. This helps prevent salt buildup and corrosion from happening underneath the grip where you can’t see it. Dry all of the pieces thoroughly before putting the knife back together.

If you are done diving for the day you can apply a light coat of silicone to the blade to prevent corrosion, but don’t use a petroleum-based lubricant. Petroleum will attract dust and sand. Use a light oil designed for knifes for lubricating and storage. You will want to use a lightweight honing or mineral oil designed for knife care. If your knife does start to rust try and clean it as soon as possible. For very light corrosion, you may be able to wipe it off with just a towel or toothbrush. Again you can also use a cleaning cloth that is designed to help remove light rust marks. For more stubborn stains and rust, soak the knife in distilled white vinegar for about three – five minutes. Remove the blade from the vinegar and wipe it down. Again, a toothbrush will work nicely for removing the lighter stuff. An abrasive sponge can be used for tougher jobs but be careful not to scrub too hard because you could scratch the blade and you can also remove some of the outer coating and it will make it rust faster. Do not use a steel wool, as that will cause more rust to form later. The steel wool will leave small pieces of steel behind that will start to rust.

Rinse the knife in fresh water in the same manner as you would for post-dive care. Dry the knife thoroughly and apply a light coat of silicone to protect against corrosion.

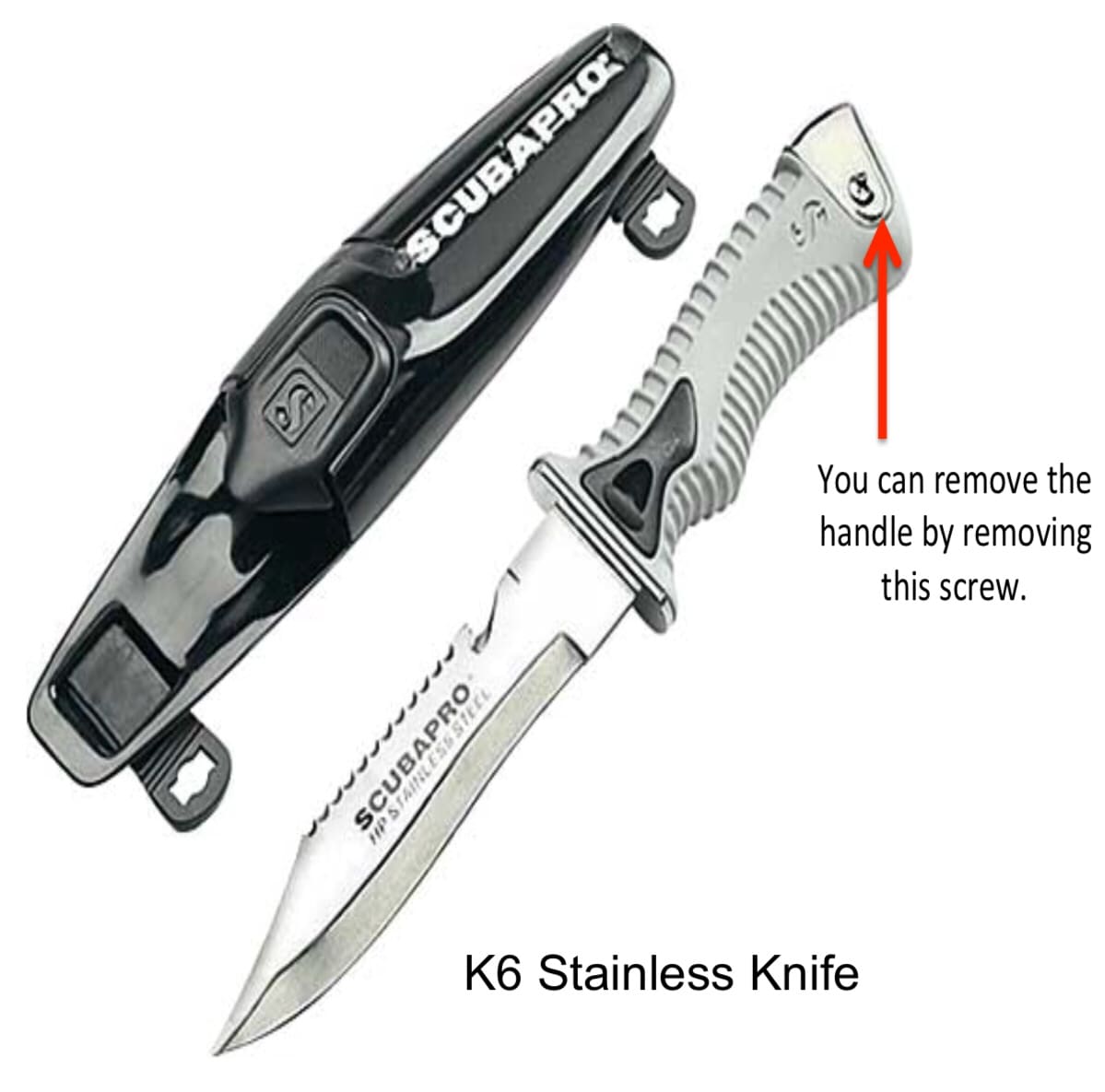

K6 Stainless Knife

Storing your knife

You can store your knife in the scabbard once you are sure both the knife and scabbard are dry. For long-term storage you should store the knife outside the sheath/ scabbard. If you have a leather sheath, that retains moisture and will cause rust. You can store the knife outside the scabbard in a cloth that has some oil on it. They make cloths that are treated with mineral oil you can use or just spray some on one. Store the knife in a dive mask box or put the knife wrapped in the cloth in a Zip lock bag.

Sharping your knife

Dive knifes can be hard to sharpen as most have a straight edge and a serrated edge to them. So you cannot really use the easy methods, like a quick pull sharpener, that you just pull the knife thru. You can use a sharpening stone for the straight edge and a ceramic rod for the serrated edge.

1. With your knife at the correct angle, slowly draw the knife down and across the stone in a smooth motion, starting at the heel and finishing at the tip.

2. The number of times this must be done will vary depending on how dull your knife is. But what’s most important is that you do the same amount of pulls on both sides of the knife.

3. After five draws, flip the knife to the other side and repeat the heel-to-tip motion.

4. Repeat this process, but instead push the knife from tip to heel. Knives are used to cut in both push and pull motions, so it’s important to sharpen them in both directions as well.

5. Flip the stone over to the finer side, and complete steps again until your knife is sharp.

Serrated Edge sharping

There are lots of ceramic rods out there so I am just going to talk about one the Lansky rod. It is tapered so it will fit all sorts of sizes of serration bevels.

1. First size the bevel by taking the rod and place it in a serrated bevel so that the angle is the same. Run the rod from the top (side closest to the spine of the blade) to the bottom (the cutting edge) a few times in each serrated groove. Try and stay with the angle of the serration.

2. Knock off the burr by taking a fine grit sandpaper or sharpening stone and remove any burr from the flat side of the serrated grooves by making a few light passes. Be sure to only take the tapered rod to the width of each serrated groove so that it does not deform them. You don’t need to use a lot of pressure with this method.

3. If you don’t understand this look on YouTube there are a ton of ways to do this.

Titanium Dive Knives

Sharping a titanium dive knife is the same as a stainless steel, but there is a difference. Most companies recommend a diamond sharpener. You will have to make sure you know what type of titanium knife you have as some are only coated with titanium. If it is called military grade it should be pure titanium. Remember when sharpening to use a light touch, titanium is easy to deformed and excessive pressure in sharpening will roll the edge causing difficulties getting a sharp edge.

SCUBAPRO Professional Knife

The SCUBAPROs TK15 is the first in a new series of Tactical dive knifes. It is built around a single piece of marine-grade stainless steel machined to achieve the ideal balance of strength and weight. Its surface is specifically polished to let water drain easily and prevent oxidation. The thickness of the stainless steel is consistent from one end to the other, creating a high level of stiffness. This is a traditional, heavy-duty, no-frills type of knife designed to handle all cutting jobs, large and small.

The blade is a generous 15cm/6in long and features a lower full-length smooth-edge and an upper serrated edge positioned close to the handle so you can maintain maximum control of the cut. A line cutter is positioned closer to the tip of the blade to enable you to easily hook lines, plus in this position it doesn’t weaken the blade. Also, a shackle key is built into the body of the blade, a great addition for boat divers.

Marine-grade stainless steel offers the best balance between cutting edge reliability and resistance to corrosion. This can be a difficult balance to achieve on the same piece of steel, but SCUBAPRO succeeded by adding a handmade polish finishing on the steel surface which promotes water run-off for long-term oxidation-free durability.

The TK15 comes with a heavy-duty handle that’s sized and shaped for solid gripping. The rugged sheath is made from fiberglass reinforced polyamide. The knife is kept in place by two teeth on the sheath matching the recesses on the handle. The sheath includes heavy-duty nylon straps for easy attachment and a SCUBAPRO branded hand cover with bungee to secure the knife to your hand under critical conditions.

Tags: Scubapro

Looks like they put a better retention system on the TK-15, I never liked the locking system on my Mako, it just doesn’t seem intuitive as you can’t unlock it while having a perfect grip on the knife.