NATICK, Mass. – Research performed in the Helmet Laboratory at the U.S. Army Combat Capabilities Development Command, or DEVCOM, Soldier Center has led to a revolutionary new combat helmet.

Due to the Soldier Center’s Helmet Lab technology, and subsequent efforts working with key industry partners, the new combat helmets will provide the warfighter protection against a higher level threat – protection that previously could only be accomplished with a much heavier applique/helmet combination.

Researchers in the DEVCOM Soldier Center Helmet Laboratory have spent the past decade working to optimize combat helmet performance by developing new modeling, design and processing techniques. Combat helmets are comprised of flat sheets of ballistic material pre-formed into a helmet shape and then processed at a high temperature and pressure.

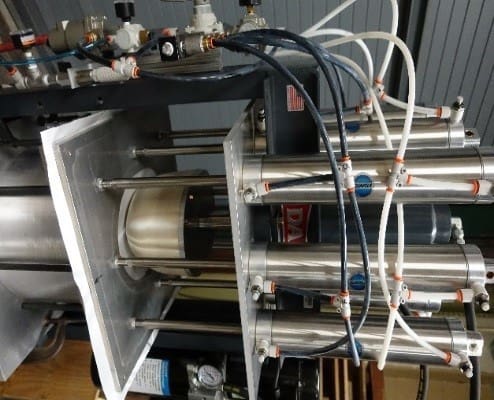

“Wrinkling and folds occur as the flat fabric conforms to the three-dimensional shape” said Jason Parker, a DEVCOM Soldier Center mechanical engineer. “These seams, wrinkles, and folds seriously degrade the ballistic performance, requiring more material and more mass to protect against a given threat. Through our research, we determined how these defects are introduced, how they affect ballistic performance, and how to eliminate them. The culmination of this research is a novel machine and process which produces a seamless, uniform helmet, free from defects such as folds and wrinkles.”

In 2015, the Helmet Laboratory developed a novel pre-form apparatus, process, and optimized helmet ply layup design. The Soldier Center used this technology to develop prototype helmets demonstrating breakthrough performance, providing a higher level threat protection that could previously only be achieved with the addition of a ballistic applique.

“In 2017, we tested prototype helmets targeting a higher level threat that were fabricated using our novel helmet preforming apparatus,” said Robert DiLalla, team lead of the Ballistic and Blast Protection Team in DEVCOM Soldier Center’s Soldier Protection Directorate. “The results far exceeded our expectation as we were getting stops well above the requirement and at 40 percent less weight than the current capability. The results were replicated with another batch of prototype helmets confirming that we had developed a new capability to significantly increase Soldier protection.”

Since 2017, the Helmet Laboratory, at the request of senior Army leadership, continued to mature and transition the technology to industry partners by establishing several Cooperative Research and Development Agreements, or CRADAs, and Research & Development contracts.

“After the Helmet Lab first demonstrated this breakthrough performance, the team worked diligently with our industry partners to rapidly transition this technology and contribute to the advancement from laboratory prototype to production ready helmets,” said David Colanto, PhD, who is the program manager for DEVCOM Soldier Center’s Integrated Multi-Threat Headborne System. “The collaborative effort with industry represents a successful technology transition and highlights the fact that Soldier Center applied research and technology demonstration efforts are critical to providing significant improvements to warfighter protection.”

In February 2021, Gentex Corporation announced that one of their Ops-Core® FAST Helmet Systems passed U.S. Government First Article Testing (FAT), a first for a helmet providing a higher level threat protection. This new helmet leverages helmet design and processing innovations transitioned through a CRADA with the DEVCOM Soldier Center’s Helmet Lab.

“This new FAST helmet is the culmination of a multi-year commitment to innovate the novel production processes necessary to manufacture helmets with next-generation ballistic materials,” said Des Walsh, vice president of Advanced Research and Development for Gentex Corporation. “It serves as an excellent example of successful, outcome-oriented government-industry collaborative development, resulting in the most advanced ballistically protective helmet shell ever qualified for production by Gentex and available to the warfighter.”

“It’s been a long road that started with an Army investment in science and technology which led to an invention,” said DiLalla. “That invention, when combined with industry knowledge, led to a finished product that offers a leap ahead level of protection. Today, the warfighter will benefit from that technological advancement. As a result of our efforts, we are currently undergoing a major renovation to our Helmet Lab having added new processing equipment to expand capabilities to help drive future research initiatives.”

By Jane Benson, DEVCOM Soldier Center Public Affairs

Tl;dr

Prototype helmet offers same protection with 40% lighter weight.

What is the higher threat level? Or is the point to just save weight?

“In 2017, we tested prototype helmets targeting a higher level threat that were fabricated using our novel helmet preforming apparatus,” said Robert DiLalla, team lead of the Ballistic and Blast Protection Team in DEVCOM Soldier Center’s Soldier Protection Directorate. “The results far exceeded our expectation as we were getting stops well above the requirement and at 40 percent less weight than the current capability. The results were replicated with another batch of prototype helmets confirming that we had developed a new capability to significantly increase Soldier protection.”

40% weight savings is excellent achievement. Kudos.

Great work. What are the technical details of the helmet? When will they be produced?

The follow up details necessary for those of us that want to get them.

I’d like to know how the US taxpayer is being rewarded for the use of the money. Yes, I want OUR soldiers to have the best equipment, and as a user of the tech, I want it for me abs my Marines. My question is, after what I’m sure is millions in R&D costs how is the government ensuring the tech isn’t stolen by the Chinese and what kind of cost reduction does the government see since they showed industry how to produce a more protective helmet at a lower weight?

RFfromNOVA,

Kit that weighs less causes less fatigue. Less Spinal column compression injuries due to military service is a real issue that causes a huge problems for soldiers quality of life. Your Taxpayer funds rehabilitation and ongoing pain management. 2 significant instances of your military influencing industry is the ongoing collaboration with FR clothing and hearing protection.

And specifically your PEO team has definitely leveraged the r&d of your armored combat shirt by retaining rights to have 3rd party companies make the products on your behalf. I cannot speak to this initiative. Maybe they did the same arrangement. MTek also worked with DOD.

US industrial complex is very strong. It is important to note many inventions created by DOD and other government institutions help society in many ways.

Your comment about foreign companies or organizations stealing the technology. I mean there is the legal intellectual property rights and patent rights they could invest in securing the technology. Your government could use ITAR and CTAT to protect against export of the goods. It is ultimately a matter of time before someone else does the same thing. Maybe someone else already has similar technology. DOD is looking to improve both your main Battle Rifle and Squad support machine gun reducing weight, sound while increasing accuracy and lethality. Also the USMC is moving to polymer cased 50cal ammo which will by your commander account will save 10-20lbs per box.

I think this is a great develop for the US Military and their allies. There are so many things being attached to helmets now a days that reducing weight and increasing protection is the fundamental.

Kudos ??

I think you missed the point of the post. I completely understand why this is important. So your first para is irrelevant to my post. I suppose you could label taxpayer funds as VA or R&D. In order for that argument to be financially reasonable you’d have to show how many millions of dollars are expected to be saved in rehab/lifetime payments. Neither the article or you did so…..

Influencing industry to invest their own dollars in research and development by creating new standards is a VERY cost effective way of doing business. The buying power of the US military causes industry to spend THEIR OWN money in order to meet the demands of a deep pockets consumer. Especially if they believe they, industry, can utilize the advertising of “we sell a product that meets XXXXX standard to the USMIL” double that if it is a SOCOM contract.

Yeah. I understand ITAR. Too bad ITAR doesn’t answer the mail for industrial espionage.

DOD isn’t NASA, they shouldn’t be developing technology for the sake of technology and human advancement. They should be laser focused on giving US warfighters a battlefield advantage. Technology that gives US soldiers a battlefield advantage which is directly created via DOD R&D, funded directly by tax dollars, needs to be protected. This will anger many of the LE readers here but a 40% weight reduction while increasing ballistic protection is significant. Perhaps this helmet should be handled at a minimum like the most high end NVGs or more like a high end aircraft weapons system. Perhaps it shouldn’t be sold outside the mil for right now. Stuff trickles down eventually but it doesn’t need to come spilling out and right into the hands of our adversaries right away.

If Gentex is allowed to manufacture these helmets in an insecure plant, or allowed to sell the production secrets to another manufacturer via licensing agreements I have a problem with it. And, because R&D often fails and it appears USDOD took on the risk and cost of this R&D, perhaps in order for the tech to be given to GENTEX they should be told they have to sell the helmet at current production costs to USDOD and can raise the cost to NATO allies. I’m not saying what that formula should look like I’m just saying it would be nice to know it was discussed and some reasonable agreement committed to. My guess is it was something like, well GENTEX makes our current Helmet so we give them this and they’ll make the new helmet. Sounds like DOD picking a winner there which they have no business doing either.

I’m a skeptic, I’ll take that label. After over 2.5 decades of seeing money burned by the pallet load I’m just calling it out and asking for the Army to show some sort of accountability.

You are 1000% correct. It isnt an “investment: if we don’t get a return. If that is US Army IP, then do they pay a price to use it or the government get a contracted discount? How are we getting any benefit here?

Sadly I don’t expect DOD accountability on budgets any time soon.

The government owns the material, but they still need outside companies to make it. Yes at some point he chinese will say they have copied it. But what they say they can do and what they do is something else. Look at all the helmets on the market for $250, that is said to be better than an Ops Core Fast helmet and that helmet costs 1600. There really is a reason the helmet costs so much.