FORT DETRICK, Md. — The U.S. Army Medical Materiel Development Activity’s Warfighter Deployed Medical Systems and the U.S. Army Medical Test and Evaluation Activity, or USAMTEAC, recently partnered at Fort Detrick to assess three commercially available medical-grade oxygen generating systems in early August.

Soldiers from Fort Bragg and Joint Base Lewis-McChord participated and received training on each system prior to the evaluation and testing. Once trained the Soldiers operated the products as if they were deployed.

During the testing process, standard-sized cylindrical oxygen tanks are vacuumed before being refilled to verify the flowrate. Next, the oxygen is tested for purity before the tanks are vacuumed and recycled through the process again.

“On the battlefield, patients who need oxygen would come to us,” said Staff Sgt. Lorrence Wilder of the 551st Medical Logistics Company at Joint Base Lewis-McChord. “For example, a field hospital may need purified oxygen and it would be our job to use one of these products to refill their oxygen supply.”

The Soldiers and the USAMTEAC personnel verify that the products meet the standards and perform as expected.

“This modernization is a two-year process,” said Austin Langdon, deputy product manager at Warfighter Deployed Medical Systems — Modernization. “In phase one, the teams gathered data and information, to develop a list of essential characteristics to describe the requirements products had to meet. That wasn’t done in a vacuum, we worked with the Future Field Integration Division, the Capability Development and Integration Directorate, and others to put the list of essential characteristics together.”

Each essential characteristic has a minimum level and a desired level that vendors must meet to be considered.

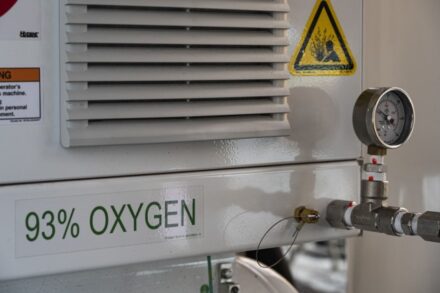

All three devices operate on pressure swing absorption systems, which take in ambient air and filter-out other gases until the oxygen reaches the desired purity level.

“We are conducting unbiased testing on one system at a time,” said Eitter Rodriguez, one of the USAMTEAC test officers. “Each system evaluated on its own merits. The tests are the same across the board. They are all different systems, but the requirements for each are the same.”

“Maintenance and sustainability are considered in addition to the test results,” said Langdon. “If two machines meet the requirements, but one requires significantly more costs to maintain, then that needs to be assessed as well.”

Evaluators say the goal is to make a selection, field and fully deliver a product to the field to take care of Warfighters. The Army Medical Logistics Command maintains and sustains the product throughout its lifespan.

“Our Medical Maintenance Operation divisions throughout the United States, Europe and Korea call us when there’s a maintenance issue,” said Leigh Anne Alexander, director of the Integrated Logistics Support Center under the Army Medical Logistics Command. “So, identifying test parameters early-on, ensures the system is doing what it is supposed to do, is really important.”

Story by Scotty Hogan

Photos by Denver Beaulieu-Hains and T. T. Parish