ABERDEEN PROVING GROUND, Md. — Army researchers are advancing the capabilities of tactical batteries as a critical piece of the military’s comprehensive effort to improve U.S.-based manufacturing and strengthen the industrial supply chain.

Engineers at the Army’s Command, Control, Communications, Computers, Cyber, Intelligence, Surveillance and Reconnaissance Center are focused on integrating advanced cell chemistry into batteries as the next generation of modernized Soldier electronics are fielded. The team is focused on developing standardized form factors for use in Soldier-worn and handheld equipment such as radios, GPS, night-vision devices, and weapons.

“By standardizing battery form factors, the Department of Defense aims to aggregate demand throughout the services and improve buying power among the industry’s battery cell manufacturers,” said Dr. Ashley Ruth, a C5ISR Center research chemical engineer. In addition, standardization avoids the old model of fielding a proprietary battery for each piece of gear, as technology developers have historically delivered unique batteries for new capabilities.

The Center is an element of the Army Combat Capabilities Development Command, known as DEVCOM.

“The Army is working on forecasting a fully developed demand signal for a range of Soldier batteries,” said Dr. Nathan Sharpes, a research mechanical engineer with the Center. “This provides an incentive for industry to onshore battery manufacturing to the United States and support the domestic industrial base and secure the supply chain. The overall DoD goal is the ability to procure cutting-edge batteries affordably and reliably with a coordinated strategy.”

The C5ISR Center’s latest R&D effort in support of battery standardization is the Operational Single Cell for Accessory Readiness, or OSCAR. The program’s benefits include safety, performance, and cost, according to Sharpes.

OSCAR research originated from the need to develop a AA form-factor military battery capable of recharging.

New electronics in the Army’s R&D pipeline can require higher instantaneous power draw than current AA form-factor batteries can provide, according to Sharpes. OSCAR will be capable of performing like a AA battery in legacy applications but also enter a high-power mode to satisfy next-generation enabler devices such as night-vision scopes that are typically mounted to a rifle or helmet.

With the capability for recharging more than 100 times, OSCAR batteries represent significant cost savings compared with existing single-use options. The C5ISR Center anticipates prototypes available for lab and safety testing in the near future.

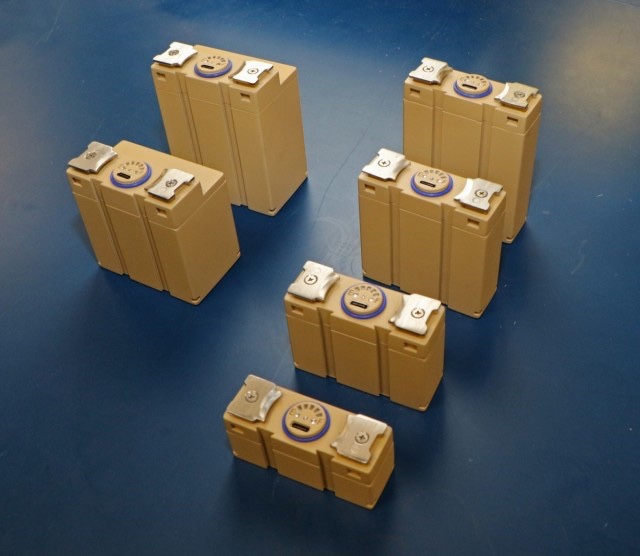

OSCAR follows the team’s successful development of the Small Tactical Universal Battery, or STUB, which is a standard family of batteries for handheld and small form factor devices, with eight sizes that share a common mechanical and electrical interface — the key to unlocking interoperability, Sharpes said. Each battery size provides a different amount of energy, from which Soldiers could choose, depending on their mission needs. This interoperable battery system seamlessly delivers the correct voltage and power level needs to any device.

Army project managers can now procure these batteries for integration into fielded Soldier-worn and handheld systems. The STUB program’s current emphasis is to mature manufacturing to ensure the Army has sufficient and consistent demand for industrial production.

These C5ISR Center’s research projects support the broader effort within the Defense Innovation Unit’s Family of Advanced Standard Batteries program, along with DEVCOM’s Ground Vehicle Systems Center and the Navy.

“We’ve committed our R&D to the collective goal of building a robust U.S.-based battery supply chain that incorporates the latest technological advancements,” Ruth said.

By Dan Lafontaine, DEVCOM C5ISR Center Public Affairs

This is backwards thinking. Standard form factors exist. Require equipment developers to use them. Help domestic production of superior chemistry to make American batteries superior and then dominate global market share. The fight of the future is going to stretch us logistically like nothing we’ve experienced in the last 8 decades. The enemy we will face WILL contest air and sea resupply efforts. Our warfighters will need to be able to put locally sourced batteries in the gear.

Hopefully they’ll tackle the 18650/21700 size next. There’s at least one battery model they could use for the added draw -some of the 18650’s that Olight makes has both positive and negative on one end allowing higher output, and retained 2xCR123 /standard 18650 buttontop use at diminished output. Would imagine this 14500 would be somewhat similar. Form factor is enough. Rechargables aren’t what they used to be- way more reliable and one of those stubs could keep you in AA’s for a month, even without adding a panel.

This isn’t a terrible idea. But you would have to run all battery powered devices on the rifle on one battery to realize any weight savings. Anything that increases the weight of a rifle is going to be non-starter.

What kind of flashlight is shown mounted in the photo?

I’m pretty sure there’s a Surefire KM3 hiding under that over-molding, based on prior images showing an affinity for SF heads, and a current pic on T-Worx’s website.