This was shared by Spuhr on Instagram.

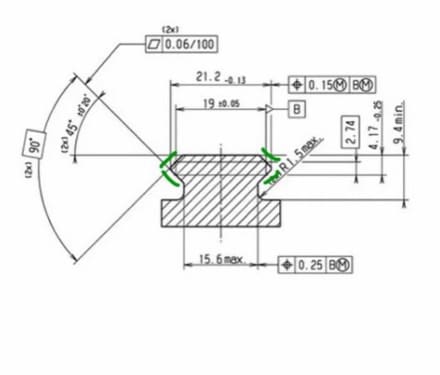

When the Picatinny rail (MIL-STD-1913) was originally designed, it was intended to use only the 45-degree angled surfaces for clamping and reference (highlighted in green on the drawing). The tolerance to the top flat surface was deliberately made very large.

Advantages of the original design (green surfaces):

• A QD mount can be attached and detached on a huge variety of rails with extremely tight control — total width tolerance is only about 0.1 mm!

• This makes the system very forgiving of manufacturing variations between different rails.

Disadvantages:

• The mount will always sit slightly canted depending on the exact width of the rail.

• For most practical purposes, this doesn’t matter at all… but it drives people with OCD absolutely crazy…

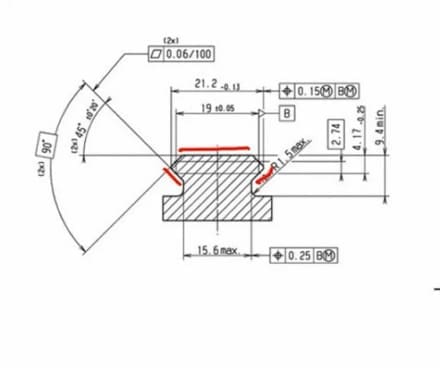

NATO’s recommendation since 2009 (STANAG 4694): Use three surfaces instead (highlighted in red): the two 45-degree sides plus the top flat as the primary reference.

Advantages:

• The mount will always sit perfectly straight and level

Disadvantages:

• In addition to the ~0.1 mm width tolerance, you now also add 0.25 mm tolerance to the top flat.

• That adds up to a cumulative tolerance of up to ~0.6 mm (0.024”).

• This works fine for screw-fixed mounts, but it’s a disaster for QD mounts — they become much harder to get consistently straight and repeatable across different rails.

What we do at Spuhr:

• Fixed mounts: We follow the NATO/STANAG recommendation (red surfaces) for maximum straightness and repeatability.

• QD mounts: We stick to the original Picatinny design (green surfaces only) to keep tolerance stack as low as possible and ensure compatibility with as many rails as possible.

The last picture shows one of our custom inspection fixtures for QD mounts — we use it to verify that they sit reasonably straight despite rail variations.

NATO really missed an opportunity by not tightening up that loose 0.25 mm top-flat tolerance — it would have made QD systems so much better!