Thursday 1 Oct, 2020 – D3O is proud to be the specified helmet suspension pad supplier in the recently awarded Integrated Helmet Protection System (IHPS) Suspension System contracts. The split awards to VisionCorps (Lancaster, Pennsylvania), and Winston-Salem Industries For The Blind Inc. (Winston-Salem, North Carolina), are Firm Fixed Price Indefinite Delivery Indefinite Quantity (IDIQ) contracts, with deliveries through 21 June 2023. Under the terms of the contract, D3O will deliver up to 100,000 suspension pad sets per year. Building on D3O’s past performance delivering IHPS helmet pads to the US Army as a sub-tier supplier during the Low Rate Initial Production (LRIP) program phase, these latest awards cement D3O’s market position as a leading provider of next generation head protection to the US Armed Forces.

The IHPS is one of four subsystems of the cutting-edge Soldier Protection System (SPS), a modular, scalable, tailorable platform designed to defeat current threats at a reduced weight in comparison to the Army’s existing Personal Protective Equipment (PPE) system. SPS increases the warfighter’s survivability, mobility and modularity by optimizing soldier protection while effectively reducing weight with the latest technologies and managing all lifecycle aspects of personal protective equipment. SPS provides the soldier with multiple levels of protection tailorable to a broad range of missions.

The IHPS consists of a helmet, with provision for adding mandible protection and/or ballistic visor for mounted use. The system is designed to protect a soldier’s head, enabling soldiers to configure its various components to optimize protection to the specific threat and mission.

D3O, a UK-based impact protection company with offices and Berry Amendment-compliant production capability in the US, was the first company to simultaneously meet the IHPS system’s rigorous 14 foot/second impact protection requirement while delivering improved performance for the traditional 10 foot/second requirement. The company is now producing a one-size-fits-all IHPS helmet pad system that is also lighter and more comfortable than the previous generation. This reduces soldier burden, allowing for increased survivability, agility, and maneuverability.

To develop the system, D3O leveraged its previous helmet pad design expertise supplying multiple Defense customers, including prominent international protective kit providers, as well as its expertise developing market-leading impact protection across the industrial, sports, motorcycle and electronics markets. The result, developed in collaboration with the National Industries for the Blind (NIB), is a helmet pad set that exceeds the requirements set by the US Army. D3O commenced IHPS Generation I LRIP in summer 2018.

Bill VanMullekom, Executive Vice President, said: “Our ultimate goal for the SPS IHPS program is to bring the benefits of next generation D3O Impact Protection to those that need it most. Our next generation helmet pad systems meet the most stringent impact standards while being suited for a wide array of helmet shells, offering maximum protection to the warfighter. D3O invests heavily in its new material and product engineering pipeline initiatives and is proud to serve US Army needs with this latest technology.”

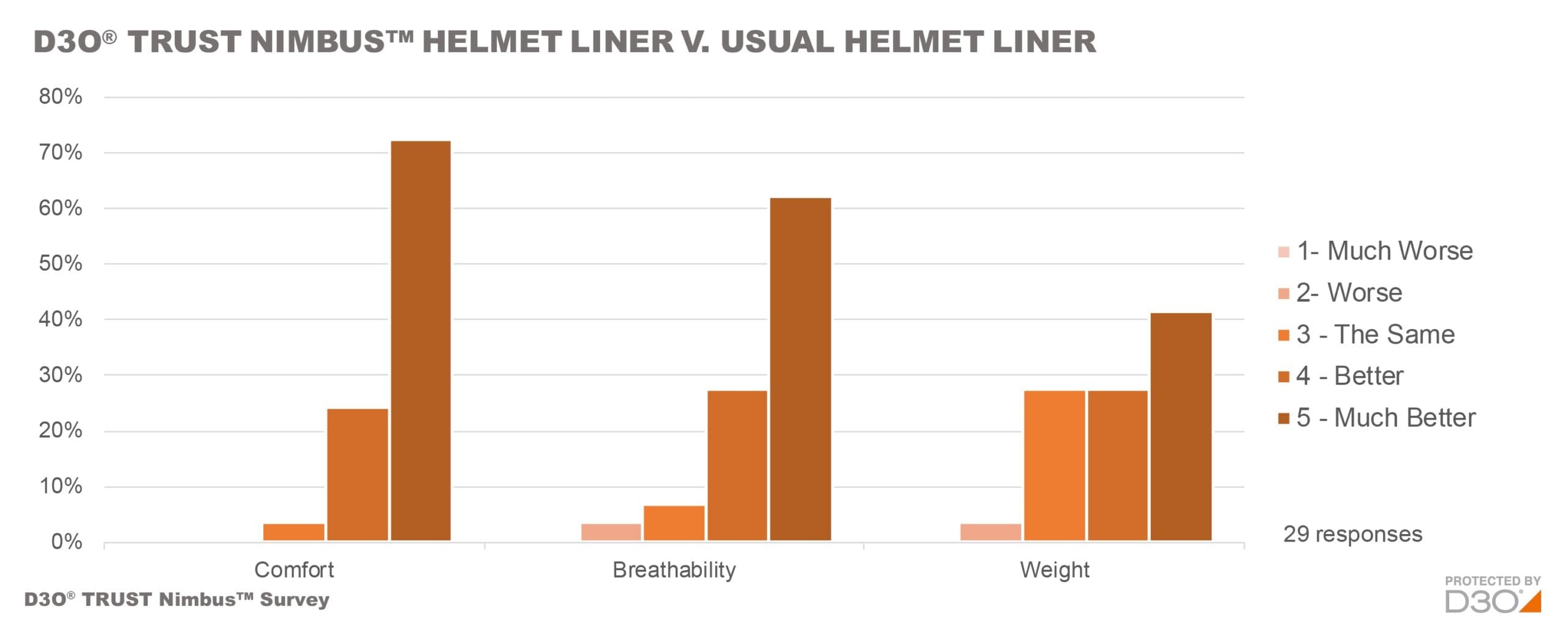

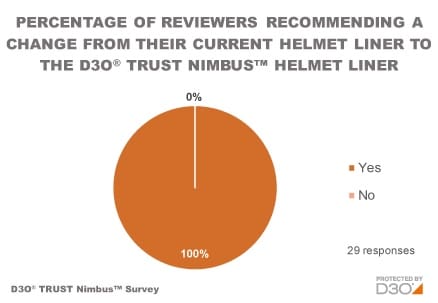

The new offering complements D3O’s helmet pad range, consisting of the original TRUST Stealth and Berry Compliant TRUST Nimbus, the company’s latest lightweight system tested for use in both aramid and polyethylene helmet shells for greater versatility. Nimbus is available in 7- and 9-pad configurations, the latter affording end users the option to remove a single pad to create a channel for over-the-ear hearing communication straps. A study conducted in the second quarter of 2020 to obtain both military and law enforcement user reviews on TRUST Nimbus confirmed it is suitable for wear all day, every day. A majority of users advised this system was better or much better in terms of comfort, breathability, weight and overall than their prior helmet liner, and 100 percent recommended a change from their prior system to the TRUST Nimbus system.

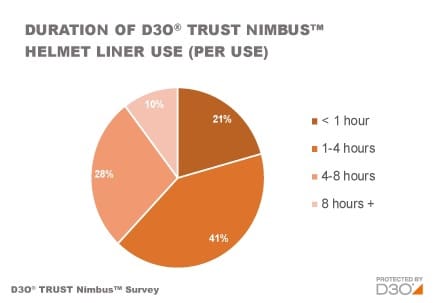

So the majority of these people who recommend the pads have used it for less than 4 hours total? That doesn’t really sound like testing….

Hi Lasse, thank you for your question, this is duration per use. The original survey question was “For how long per use did you wear D3O TRUST Nimbus pad system?”. The graph title has now been added to accordingly, for 100% clarity.

This system is long overdue. Law enforcement across the nation, should be requesting these in mass numbers. With all of the chaos ensuing major liberal cities across the UNITED STATES, these are needed and should be mandated by police chiefs everywhere.

Not a fan of the IHPS. I am sure the new suspension system is better than the old ACH pads but the IHPS helmet itself is barely better than the old ACH. I have both sitting here on my desk as I write this. The single best thing the Army could have done is go with a high cut profile and the OPSCORE style mounting accessory rail to lighten the overall weight. Instead Uncle Sam did his own thing and now we have a proprietary mounting system that has no aftermarket accessibility, doesn’t solve the over the ear coms issues and is barely any lighter than the old ACH.

#WINNING???

I guess now they have a better suspension system at least. Cool I guess. Hopefully it will help with the extra weight we are bolting to the helmet.

This news is actually surprising. For those who don’t know, about 10 or so years back, D3O submitted their helmet pads for evaluation in the army combat helmet and it was found to be incredibly bad at reducing forces to the head. In fact, it made it worse , as the D3O used at that time hardened up so much on impact that forces transmitted to the test dummy head were nearing permanent damage/fatality levels. The actual study results are/is open source and should be searchable for those who want scientific backed specifics on all the pads tested at that time.

Hello PLiner, thank you for your comment.

D3O currently has almost 30 active material grades of different material families, used in everything from phone cases, to CE-certified motorcycle protection. Each is carefully tuned over a period of time – sometimes several years – for its specific application.

The IHPS suspension system is the result of years’ worth of research and development. It either meets or exceeds the stringent performance parameters set by the US Department of Defense. With this in mind, the results of a study conducted 10 years ago serve to reinforce the point that R&D expertise is crucial to meet the needs of the US Army.