FORT BELVOIR, Va. (Sept. 11, 2025) — The Army recently awarded $65.5 million in delivery orders Sept. 11, 2025, to Hardwire LLC and Leading Technology Composites, Inc., for the production of 72,179 Lightweight Small Arms Protective Inserts (LSAPI). The awards mark the official start of production for LSAPI, the newest component of the Soldier Protection System under Project Manager Soldier Survivability.

The official contract, awarded under the Army’s existing multiple-award indefinite delivery/indefinite quantity (IDIQ), allows the Army to place orders with approved vendors as requirements are finalized. Delivery Orders W91CRB-25-F-A210 (Hardwire) and W91CRB-25-F-A211 (LTC) were issued under Notice of Fair Opportunity 0001. The total delivery order value of $65,564,335.70 covers 72,179 plates, with anticipated delivery to Program Executive Office (PEO) Soldier within 18 months, no later than March 15, 2027.

LSAPI plates are approximately 30% lighter than the current Enhanced Small Arms Protective Insert (ESAPI) Generation III, reducing the Soldier’s combat load while maintaining ballistic protection. The plates also use a shooter’s cut geometry to improve mobility and range of motion. LSAPI integrates with the Army’s Modular Scalable Vest (MSV) Gen II and other systems in the Soldier Protection System (SPS) family of equipment.

“The Lightweight Small Arms Protective Insert award reflects our team’s dedicated effort to advance and optimize Soldier protection,” said Lt. Col. Ken Elgort, product manager for Soldier Protective Equipment (PdM SPE). “With this milestone, LSAPI moves into production and will soon begin fielding alongside the Modular Scalable Vest, reducing combat load while maintaining state-of-the-art ballistic performance. It also reflects a major win for domestic manufacturing and a proud moment for our team as we deliver on PEO Soldier’s commitment to equip Soldiers with world-class protection,” he added.

The LSAPI award is the latest step in modernization under Product Manager Soldier Protective Equipment (PdM SPE), Project Manager Soldier Survivability (PM SSV), and Program Executive Office (PEO) Soldier, reducing weight, enhancing lethality and delivering modular protection across the Army’s combat formations.

I had questions when these contracts were announced a month ago.

Some were now answered, some weren’t.

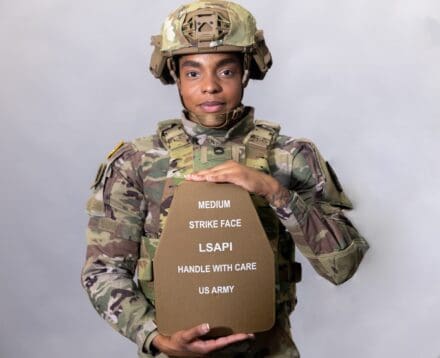

The initial announcements indicated that LSAPI’s were for small frame men and/or female soldiers, the award and contract size make sense for that use case. However, the image appears to show plates that are dimensionally similar, if not identical, to Gen IIIS ESAPI.

How are LSAPI 30% lighter, if they are the same size/shape as VTP ESAPI? The notice specifies that they “maintain ballistic protection”…what standard? ESAPI Gen III spec, or a lower protection standard?

If LSAPI protection standards are lower…how low? Rev E SAPI/ISAPI would be understandable (though unadvisable IMO), anything else would be quite problematic.

If LSAPI do meet ESAPI Gen III protection standard…how? Was there a significant material advance that allowed for the same performance at a lower weight?

Additionally, are side plates covered by these contracts, or will soldiers who wear torso LSAPI be issued Gen III ESBI as a side plate?

I also curious what else is going on with the VTP family of plates…at the last update I was aware of, only 1 manufacturer had successfully passed first article testing of VTP XSBI… and no manufacturers had successfully completed FAT for VTP XSAPI.

30% lighter huh? Probably to offset the the gain in weight from the M7 and it’s ammo.

Whatever happened to all those XSAPI plates? Did the Taliban get a hold of them during the disastrous withdrawal from Trashghanistan during the Biden administration?

IIRC XSAPIs sat in a warehouse because they’re too damn heavy and no one wants to wear them unless a war breaks out where the enemy is using AP rounds as general issue.

Pretty much.

They sat in Kuwait for a long time, though they’ve likely been stateside for a longer time.

I will say, they weren’t as heavy as they were made out to be. XSAPI’s were actually lighter than some of the alumina ESAPI’s issued in the early GWoT.

Still, the Army wants to have plates that can defeat medium caliber tungsten threats (as opposed to traditional hardened steel core) in their armor portfolio, so they are working on a next gen XSAPI.

They targeted a 5-10% weight reduction for the Gen III ESAPI and got it. They want something similar for the next gen XSAPI…but have had trouble with OEM’s passing first article tests.

Think about HardWire and what they make, and who was the original order for the LSAPIs and who that branch was fighting mostly… that occam’s razors all but the side plate questions.

I’m partially following you…

Hardwire predominately makes LE armor. The initial LSAPI order was for “small frame male and/or female soldiers” in the Army.

I’m not sure how that relates to protection though…unless you’re positing that female soldiers are unlikely to find them selves in the CCF, and thus can make do with a lower protection standard…

Still, if that’s what you’re getting at, it begs the question…what is this new lower standard?

You could drop a couple of the more exotic threats in the ESAPI threat profile and drop some weight, but IMO, maintaining standard steel core medium caliber and light AP protection is a must.

That’s a swimmer’s cut.

Yes and no.

“Swimmers” cut is a very specific geometry that comes out of SOCOM’s Spear line. SOCOM swimmers plates have a wide top edge, sharper corner relief, and are shorter than SAPI spec counterparts. Much shorter.

In contrast, the Gen III ESAPI (and this LSAPI) are multicurve plates with a shorter top edge and much more severe corner relief, but they maintain SAPI/ESAPI plate length.

That’s important because swimmer plates are optimized for…swimming, and the trade offs necessary for that.

True SOCOM swimmer plates actually leave some pretty crucial sections of the wearer’s vitals exposed.

The Gen III ESAPI cut fixes that.