Lakewood, WA – Grey Ghost Precision, leading manufacturers of accurate, reliable, and attainable weapon systems, is excited to announce the hiring of Jason Curns as the company’s Vice President of Firearms, effective September 25th. In his new position, Curns will be responsible for setting the strategic direction for all sales, customer service and marketing initiatives for the Grey Ghost Precision brand.

“Through his combined passion for the firearms industry and undeniable track record in personal customer service and care, adding Jason to the Grey Ghost Precision team was one of the most common sense decisions we’ve ever made,” said Grey Ghost Precision, CEO Casey Ingels. “His extensive experience in the commercial sales and firearms industry as a whole positions him to help lead our team and take our products to the next level.”

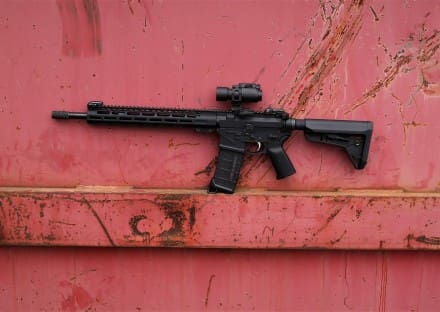

Curns joins GGP with more than 22 years of combined experience in sales, customer service, customer logistics, manufacturing and supply chain. His previous experiences include the development and execution of Grey Ghost Precision’s premier rifles, the S-Series Heavy and Light, under the partnership of then-Mega Arms (now ZEV Technologies).

“It’s an honor to be aligned with such strong, brand with Grey Ghost Precision,” Curns said. “Within the team at GGP, there is such a strong, collective passion that mirrored my own personal ethos. One that was not just for the products, but for the end-users. The primary focus is to connect with the consumers on a level that most manufacturers cannot, because they don’t try to establish that relationship of trust and reliability. Through this passion and strategy we can continue to grow the GGP brand and set ourselves further apart from the field.”